Each kinds of roll forming machines (such as steel roof, floor deck, roller shutter door, door guider, door frame, storage bracket, purlins) are acceptable.

Product name: Steel Metal Floor Deck Roll Forming Machine

This steel metal floor deck roll forming machine has been designed into 24 stations roll forming, with dot and embossing forming sections on floor deck top. To keep whole floor deck panel can be installed well on steel construction, the steel floor deck sample should be straight and the cutting of place should be smoothly, see bellow sample pictures, the embossing is for decoration function and whole sample should be flat not any bend. Normally, this type of steel floor is together working with concrete and sand.

For ensure whole steel metal floor deck roll forming machine is working safe enough, the running indicator is another new safety design of ours, this is the machine working state indicator.After we switch on the power supply, this indicator will be light. It can remind staffs work more carefully after seeing the indicator is light, also good for reminding staffs switch off the power supply after been off duty every day.

Due to floor deck raw material thickness normally is bigger, there is hydraulic pre-cutter device on metal floor deck roll forming machine beginning end, the hydraulic motor can be the same unit as post hydraulic cutting device, it can cut the waste material head when off it needs,and this cutting action can be finished on PLC control system.

All the hydraulic cutting type for steel sheet decking floor roll forming machines are the three pieces cutting blades, two fixed pieces at bottom and one movable piece cutting blade on up side. We also called this type of cutting type into waste cutting, because there are small waste material come out after floor deck panel has been cut off. All the waste material type cutting off are for keeping steel deck's cutting end is more beautiful.

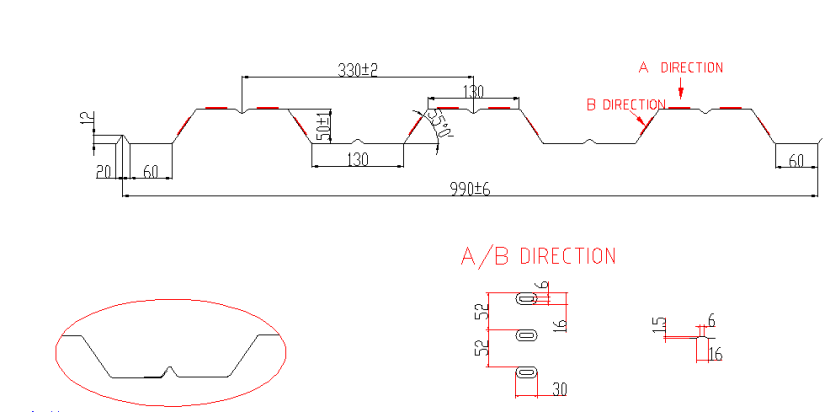

Profile Design Drawing

The raw material width is 1220mm, the material thickness is 0.8-1.2mm, with embossing and dot on surface, if you need any custom design of steel deck floor roll forming machine, feel free to contact with us soon.

Technical Parameters

|

Parameters

|

Specification

|

|

Voltage

|

380V/50HZ/3PH or customized

|

|

Driving Motor

|

15KW*2

|

|

Forming Steps

|

24 steps

|

|

Working Speed

|

10-15m/min

|

|

Thickness for Steel

|

0.8-1.2mm

|

|

Shaft Diameter

|

95mm

|

|

Shaft Material

|

High grade 45# forged steel

|

|

Roller Material

|

G45# steel, CNC lathe,polished and chrome plated

|

|

PLC Cabinet

|

Schneider, Delta

|

|

Encoder

|

Omron

|

|

Sprocket Wheel

|

45 steel high-frequencies quench

|

|

Cut-off System

|

Post cutting, no waste cutting

|

|

Cutting Blade Material

|

Cr12 steel

|

|

Machine Frame Material

|

Fine welded structural steel;

|

|

Raw Material

|

GI steel G330-550

|

|

Painted Color

|

Blue+Orange Or Customization

|

|

Overall Size

|

13500*1650*1750mm

|

|

Weight

|

120000KGS

|

For whole steel deck roll forming lines, we can matched with 7tons hydraulic uncoiler, safety cover, product rack or product pneumatic product stackers, it can be customized manufacture.