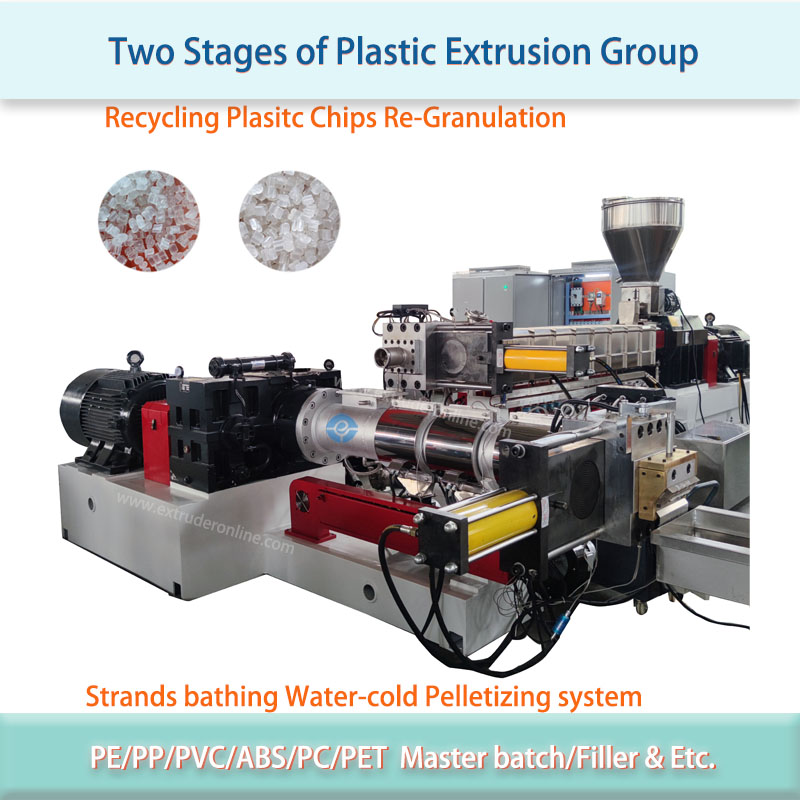

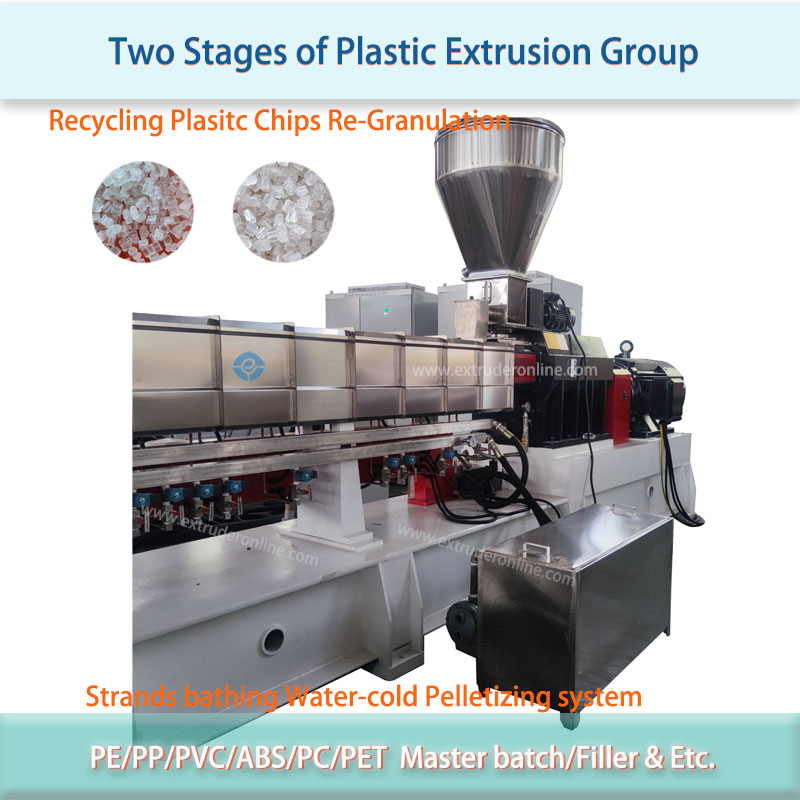

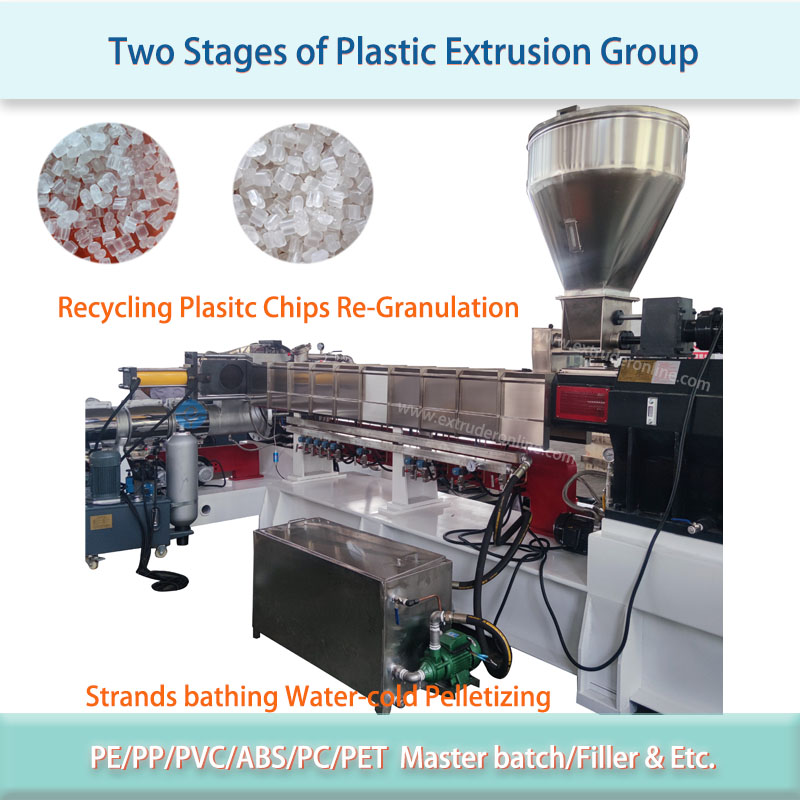

Strand Bathing Water cooled pelletizing system for 75-180 Two stage plastic polymer extruder

Two Stage of Plastic Extrusion Group

HS CODE: 8477.2010

https://youtu.be/ALI8Ka1iETk

Usage: This machine extrusion group is used for: PP chips ( has broken, the size is less than 8mm for each piece.) re-granulation. The machine is also could be used for heat sensitive material and high percentage added filler, CaCo3 (Calcium Carbonate) powder, BaSo4(Barium Sulfate) powder, Talcum powder, black carbon and Etc.

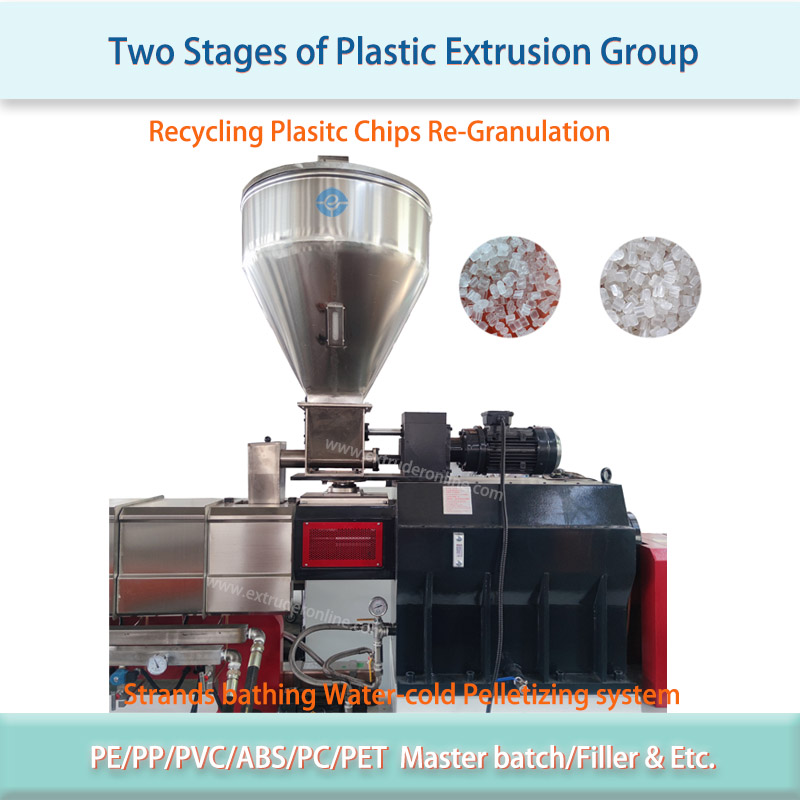

This machine is special for waste PP chips to re-granulate them into plastic particles, the model is 75/180, the group has two stages:

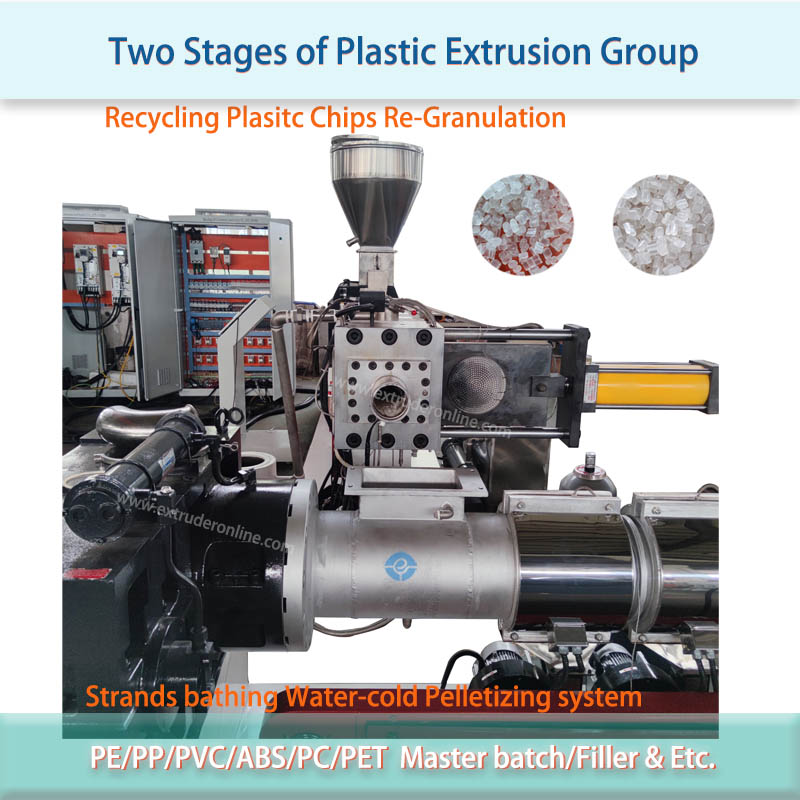

1) The first stage is: Twin screw plastic extruder, model: SHJ-75B, equipped 132KW AC motor, L/D ratio is : 40:1, 500rpm, heating power is around 50KW;

2) And the 2nd stages is single screw plastic extruder: Screw diameter is 180mm, L/D ratio: 9:1, main motor 75KW, 6 poles , 60rpm, 25Kw for heating power, and total installation power is around 300KW, Actual power consumption: total power* 70%, and output capacity is around 500Kgs/hr.

The machine line present scope is : HOST with oil cooling system for gearbox, water cooling system/heating system/air discharging system/vacuum system for barrels, screen change and extrusion system for die head, (75B twin screw plastic extruder + 180 single plastic extruder), water trough, air knife(two heads), pelletizer, power cabinet with PLC+ Touch screen.

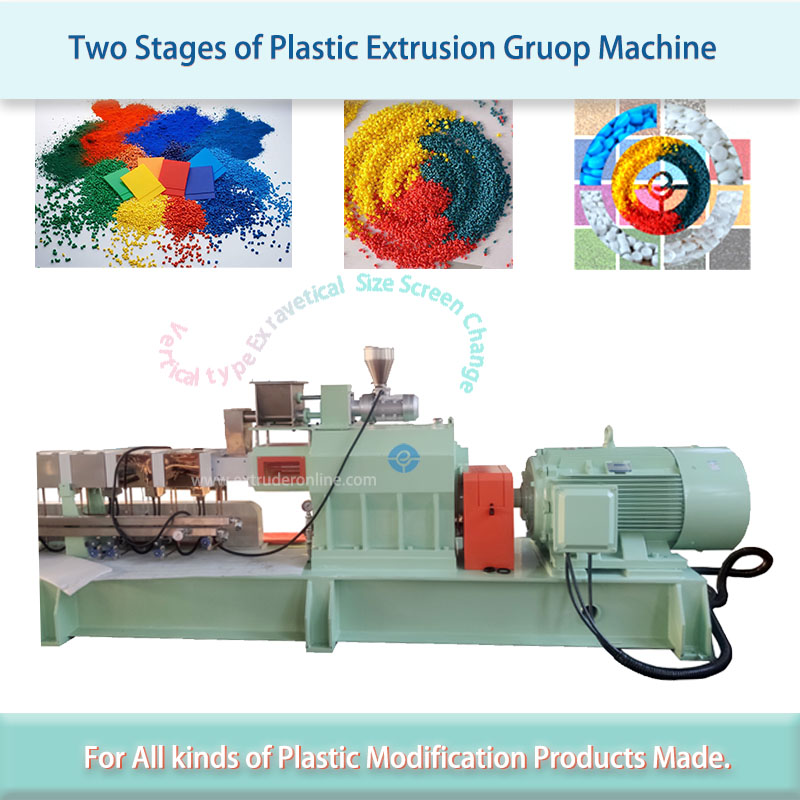

Two stage extruder mode, Standard type of 2 stages of extrusion group is equipped twin screw plastic extruder on the first stage, and the 2nd stage is single screw extruder, like TS50/D120, TS65/D150, TS75/D180, TS95/D200 and over; but we have different type of two stage plastic extusion machine group:

1) Twin screw extruder in 1st stage, and single screw extruder in 2nd stage:

50/120;65/150; 75/180; 95/200;

2) Single screw extruder in 1st stage, and twin screw extruder in 2nd stage

120/50; 150/65; 180/75; 200/95 (or 220/95);

3) Single screw extruder in 1st stage, and twin screw extruder in 2nd stage

120/120; 120/150; 150/150; 150/180 (or 150/200);

This machine extrusion group is used for:

1) heat sensitive material, like to say PVC cable, cross-liked material, & Etc.;

2) high percentage added filler, CaCo3 (Calcium Carbonate) powder, BaSo4(Barium Sulfate) powder, Talcum powder, black carbon and Etc.

The high-speed of twin screw extruder is for material melting, compounding, plasticizing and extrusion into 2nd stage: single screw extruder;

The 2nd stage: low speed of single screw plastic extruder is for material’s temperature controlling and extrusion to match the designed output capacity and quality demands.

The representative material of this extruding group machine is PVC cable granules, high percentage of CaCo3 Fillers making;