Product Overview

|

Product Name

|

Frequency Inverter/ AC Drive

|

|

Model Number

|

V5-BA-4Txx

|

|

Power Range

|

7.5kW-90kW

|

|

Rated Input Voltage

|

3 phase 380V/480V

|

|

Rated Output Voltage

|

3 phase 0 to rated input voltage

|

|

Input Frequency

|

50Hz/60Hz

|

|

Adaptable Motor

|

Asynchronous Motor

|

|

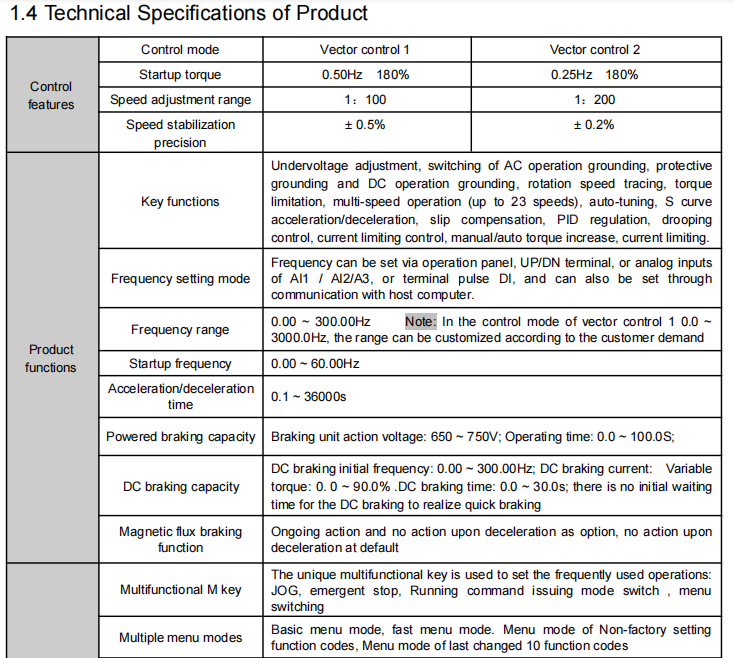

Control Mode

|

V/F Control, Vector Control, Sensorless Vector Control, Vector Torque Control

|

|

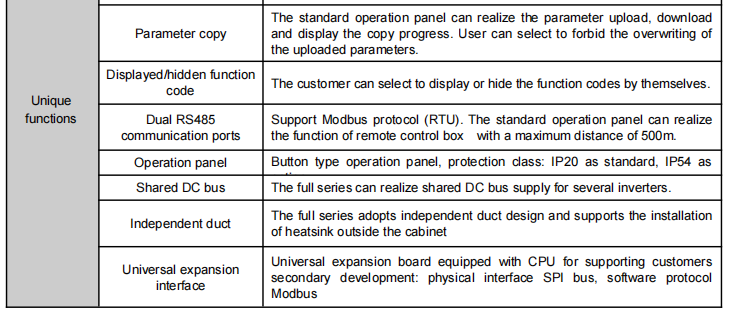

Communication

|

Modbus 485 RTU

|

|

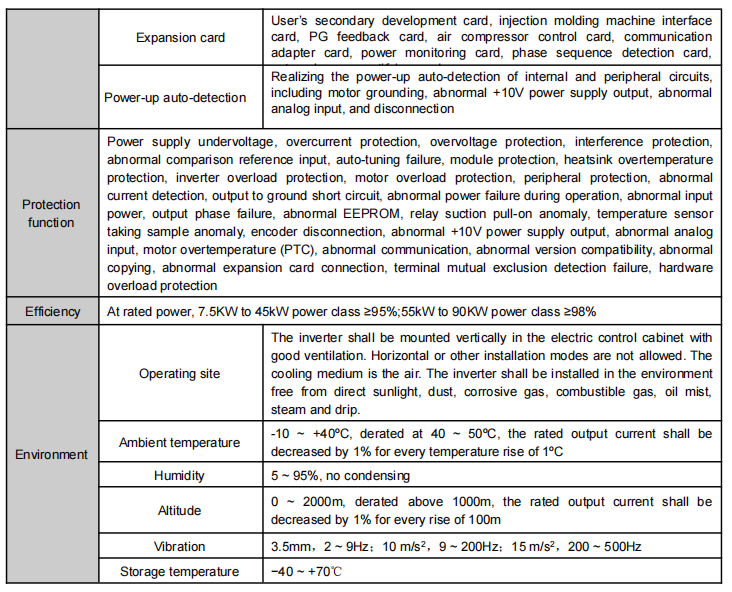

IP Class

|

Standard IP20

|

|

Overload Capacity

|

150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag feature)

|

Feature

■ Designed for requirements of spinning frames in textile machinery with convenient installation outside cabinet;

■ Suitable for dusty industrial sites, and the radiator is easy to clean;

■ After the inverter temperature exceeds the set value, it reminds the user to clean the radiator and fan;

■ Easy to operate, single button to stop, being zero on full yarn and wire break;

■ Built-in swing frequency function can output triangle frequency and kick frequency to prevent yarn overlap and facilitate unwinding;

■ Stop automatically to avoid wire break ;after the pulse feedback signal misses;

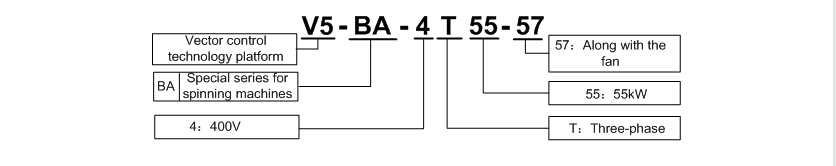

Model Explanation

Product Catalog

V5−BA−4T□□□ ;

|

Power (kW)

|

7.5

|

11

|

15

|

18.5

|

22

|

30

|

37

|

45

|

55

|

75

|

90

|

|

Adapter motor power (kW)

|

7.5

|

11

|

15

|

18.5

|

22

|

30

|

37

|

45

|

55

|

75

|

90

|

|

Output

|

Voltage (V)

|

3-phase 0 to rated input voltage

|

|

Rated current (A)

|

17

|

22

|

30

|

37

|

44

|

56

|

72

|

91

|

110

|

142

|

176

|

|

Overload capability

|

115% 1 minute, 160% 0.5 seconds, interval 10 minutes (inverse time characteristic)

|

|

Input

|

Rated voltage / frequency

|

3-phase 380V/480V; 50Hz/60Hz

|

|

Allowable voltage range

|

323V ~ 528V; voltage imbalance: ≤ 3%; allow frequency fluctuation: ± 5%

|

|

Rated current (A)

|

19

|

26

|

33

|

41

|

48

|

62

|

79

|

100

|

121

|

156

|

194

|

|

Brake unit

|

Built-in as standard

|

Built-in as optional

|

|

IP

|

IP20

|

|

cooling method

|

Forced air cooling

|

Model table

|

Voltage

|

Model

|

Three-phase 400V variable torque / light load application

|

|

Motor (kW)

|

Rated output current (A)

|

Rated input current (A)

|

|

400V

|

V5−BA−4T7.5

|

7.5

|

17

|

27.9

|

|

V5−BA−4T11

|

11

|

24

|

39

|

|

V5−BA−4T15

|

15

|

30

|

50.3

|

|

V5−BA−4T18.5

|

18.5

|

37

|

60

|

|

V5−BA−4T22

|

22

|

44

|

69.3

|

|

V5−BA−4T30

|

30

|

56

|

86

|

|

V5−BA−4T37

|

37

|

72

|

104

|

|

V5−BA−4T45

|

45

|

91

|

124

|

|

V5−BA−4T55

|

55

|

110

|

150

|

|

V5−BA−4T75

|

75

|

142

|

190

|

|

V5−BA−4T90

|

90

|

176

|

235

|

Installation Dimension

V5−BA Outline and installation dimensions ; ;V5−BA−57 Outline and installation dimensions

V5−BA series Outline and installation dimensions and approximate weight

|

Voltage

|

Model

|

Outline and installation dimensions (mm)

|

weight (kg)

|

|

W

|

H

|

D

|

W1

|

H1

|

D1

|

W2

|

Hole d

|

|

V5−BA−4T7.5

|

206

|

303

|

153

|

166

|

251

|

96

|

136

|

8

|

6.5

|

|

V5−BA−4T11

|

|

V5−BA−4T15

|

236

|

386

|

201

|

236

|

318

|

102

|

170

|

8

|

9.5

|

|

V5−BA−4T18.5

|

|

V5−BA−4T22

|

345

|

483

|

238

|

295

|

410

|

130

|

220

|

8

|

18

|

|

V5−BA−4T30

|

|

V5−BA−4T37

|

|

V5−BA−4T45

|

400

|

610

|

297

|

340

|

520

|

183

|

260

|

10

|

30

|

|

V5−BA−4T55

|

|

V5−BA−4T75

|

470

|

639

|

302

|

410

|

545

|

183

|

320

|

10

|

40

|

|

V5−BA−4T90

|

V5−BA−57 series Outline and installation dimensions and approximate weight

|

Voltage

|

Model

|

Outline and installation dimensions (mm)

|

weight (kg)

|

|

W

|

H

|

D

|

W1

|

H1

|

D1

|

W2

|

Hole d

|

|

V5−BA−4T7.5−57

|

206

|

303

|

185

|

166

|

251

|

96

|

136

|

8

|

7.5

|

|

V5−BA−4T11−57

|

|

V5−BA−4T15−57

|

286

|

386

|

245

|

226

|

308

|

102

|

170

|

8

|

10.5

|

|

V5−BA−4T18.5−57

|

|

V5−BA−4T22−57

|

345

|

482

|

286

|

285

|

400

|

130

|

220

|

8

|

19

|

|

V5−BA−4T30−57

|

|

V5−BA−4T37−57

|

|

V5−BA−4T45−57

|

400

|

610

|

343

|

330

|

520

|

183

|

260

|

10

|

31

|

|

V5−BA−4T55−57

|

|

V5−BA−4T75−57

|

470

|

639

|

350

|

400

|

545

|

183

|

320

|

10

|

41

|

|

V5−BA−4T90−57

|

Optional Expansion Card

|

category

|

name

|

model

|

Function Description

|

reference

|

|

Operation panel

|

Operation panel (shuttle ;type)

|

V6−DP01

|

Full range of models

|

P2−**

|

|

Operation panel (button type)

|

V6−DP02

|

Full range of models

|

P2−**

|

|

Text display

|

EX−MT01

|

Man-machine interface - text display

|

P2−**

|

|

touch screen

|

EX−MT02

|

Human-machine interface - touch screen

|

P2−**

|

|

Fake panel

|

V6−DP03

|

Customer option

|

P2−**

|

|

Pallet

|

V6−DP05

|

Operation panel mounting accessories

|

P2−**

|

|

Expansion Card

|

Power monitoring card

|

EX−PA01

|

Three-phase input power supply phase loss / instantaneous power failure monitoring

|

P2−**

|

|

Phase detection card

|

EX−PA02

|

Three-phase input power phase detection

|

P2−**

|

|

External power rectifier card

|

EX−RF01

|

Control power is provided by external power supply

|

P2−**

|

|

Programmable CAN bus expansion card

|

EX−CA05

|

;

|

P2−**

|

|

Profibus DP communication card

|

EX−CA06

|

;

|

P2−**

|

|

Keyboard extension cord

|

2 m keyboard extension cable

|

CB1−200

|

;

|

P2−**

|

|

3 m keyboard extension cable

|

CB1−300

|

;

|

P2−**

|

Applications

Representative Industry

The textile spinning frame can also be used in other industries where dust is frequently cleaned.