Overview

TianKang HongJi Coplanar Five Valve Manifold (for Gas) is specially engineered for natural gas transmission and measurement applications. Featuring a robust sector-shaped body, this manifold integrates two isolate valves, two equalize valves, and one vent valve to ensure safe, accurate, and stable pressure control. Its optimized internal flow path is designed to meet the demanding requirements of natural gas pipelines, metering systems, and pressure transmitters, providing reliable isolation, calibration, and system protection under continuous operation.

Manufactured from corrosion-resistant materials and built to withstand high-pressure and high-purity gas environments, this five-valve manifold delivers enhanced sealing performance, minimized leakage risk, and long service life. It is widely used in natural gas distribution stations, pipeline monitoring systems, and instrumentation skids, offering a compact, safe, and maintenance-friendly solution for precision natural gas control.

Technical Specifications

| Type |

Coplanar Type

|

Net Weight |

3.3kg |

| Body Material |

316L,Alloy |

Manufacturing Capacity |

1800 pics/Month |

| Type of Connection |

Thread/Flange |

Warranty |

1 year |

| Seal Type |

Hard Sealing |

Manufacturing |

Forging and CNC |

| Packing |

PTFE/Graphite |

Pressure Range |

6000Psi-10000Psi (414Bar-690Bar) |

| Media |

Liquid, Gas, Steam, Oil |

Inlet/outlet |

1/2 NPT, 1/2 BSPP, M20*1.5 |

| Test/Vent |

1/4 NPT with Plug |

Orifice: |

0.157(4.0 mm) |

| Graphite |

-65°F to 1200°F (-54℃ to 649℃) |

PTFE |

-65°F to 450°F (-54℃ to 232℃) |

Applications

- Oil & Gas Industry: Valve manifolds play a vital role in controlling pressure and flow in oil and gas operations. They ensure safe isolation of high-pressure systems during drilling, refining, and flow measurement processes. Their reliable performance enhances system integrity, minimizes downtime, and supports accurate instrumentation across upstream and downstream applications.

- Chemical & Petrochemical Plants: In chemical and petrochemical facilities, valve manifolds ensure precise control of process fluids and gases. They help maintain stable operating conditions in reactors, distillation columns, and mixing systems. By providing dependable isolation and venting, manifolds enhance safety, prevent leaks, and support accurate monitoring of chemical reactions.

- Power Generation: Power plants rely on valve manifolds to regulate steam and water flow in boilers, turbines, and auxiliary systems. These manifolds allow for safe pressure measurement, system balancing, and quick isolation during maintenance. Their robust design ensures reliable performance in high-temperature and high-pressure environments typical of power generation systems.

- Pharmaceutical & Biotechnology: In pharmaceutical and biotech applications, valve manifolds provide hygienic fluid control essential for sterile processing. They ensure contamination-free manufacturing by enabling precise isolation, cleaning, and calibration. Designed for sanitary compliance, these manifolds support critical operations in vaccine production, fermentation, and laboratory testing environments.

- Water Treatment & HVAC Systems: Valve manifolds regulate flow and pressure in water treatment plants and HVAC networks. They optimize filtration, distribution, and temperature control while simplifying maintenance through easy system isolation. Their durable, corrosion-resistant construction ensures dependable performance in water purification, cooling, and heating applications.

- Laboratories & Research Facilities: In laboratory and research setups, valve manifolds enable accurate control of multiple fluid channels. They support complex testing, sampling, and calibration systems where precision is essential. Their flexibility and leak-tight performance make them indispensable for experimental setups, analytical instrumentation, and pilot-scale process systems.

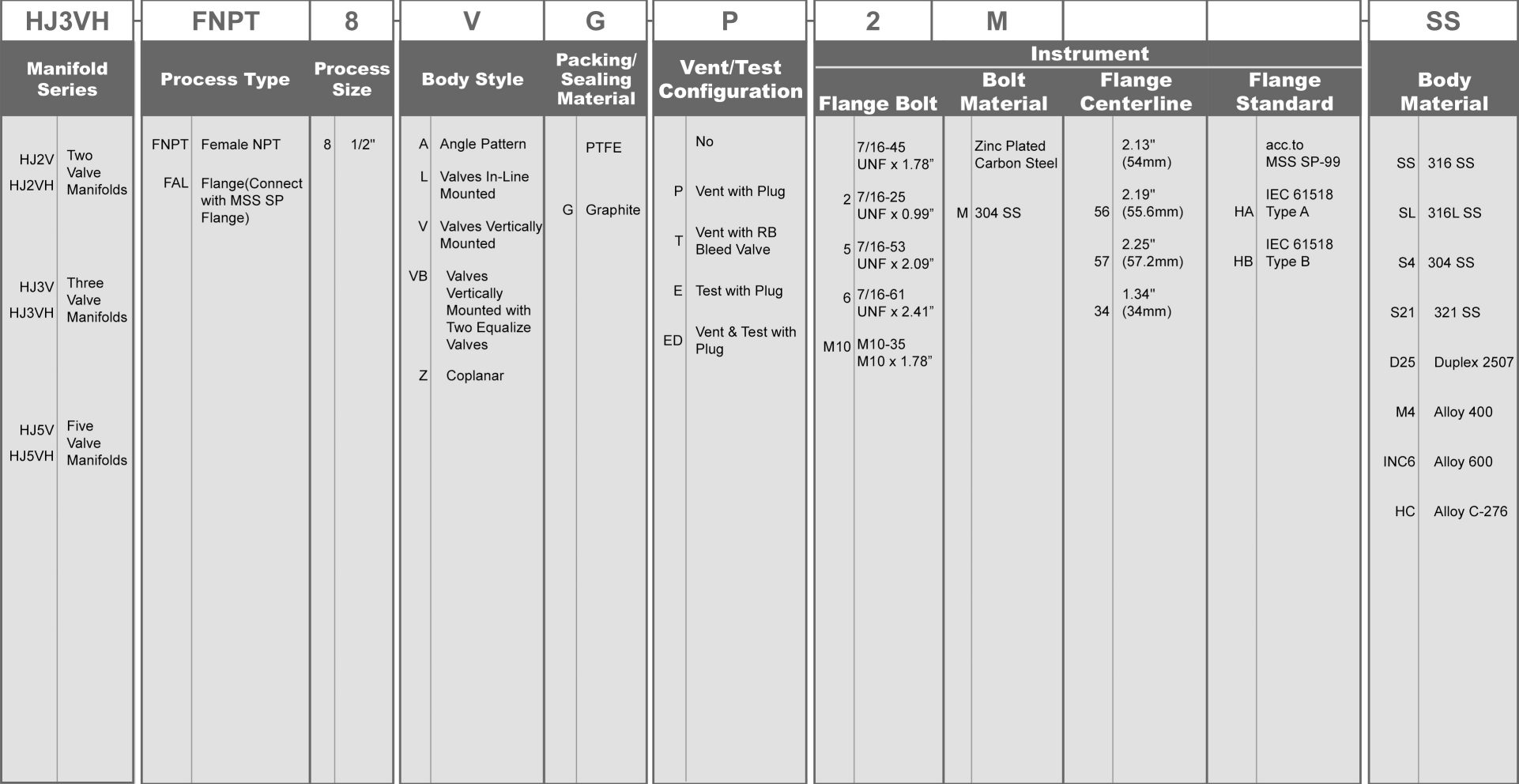

Ordering Number Description

Notes:

- Standard manifold instrument is flange (according to MSS SP-99), flange distance (center-to-center) is 2.13 (54 mm).

Distance of 2.19 (55.6 mm) suitable for transmitters of range 6, 7 and 1151.

Distance of 2.25 (57.2 mm) transmitters of range 8 and 1151.

- Ordering Number Indication illustrates the classification and combination of Hongji products, which can not be randomly combined.

- For those valves made of other type of material other than listed ,please contact the Hongji sales personnel.

- If an oxygen-dedicated valve manifold is required, include “O2” in the basic order number, for example:HJ2V-MNPT8-FNPT8-H-P-SS-O2

Customization & Technical Support

• E-Mail: overseasales@tiankang.com

Sales Support:

• E-Mail: sales06@tiankanginternational.com