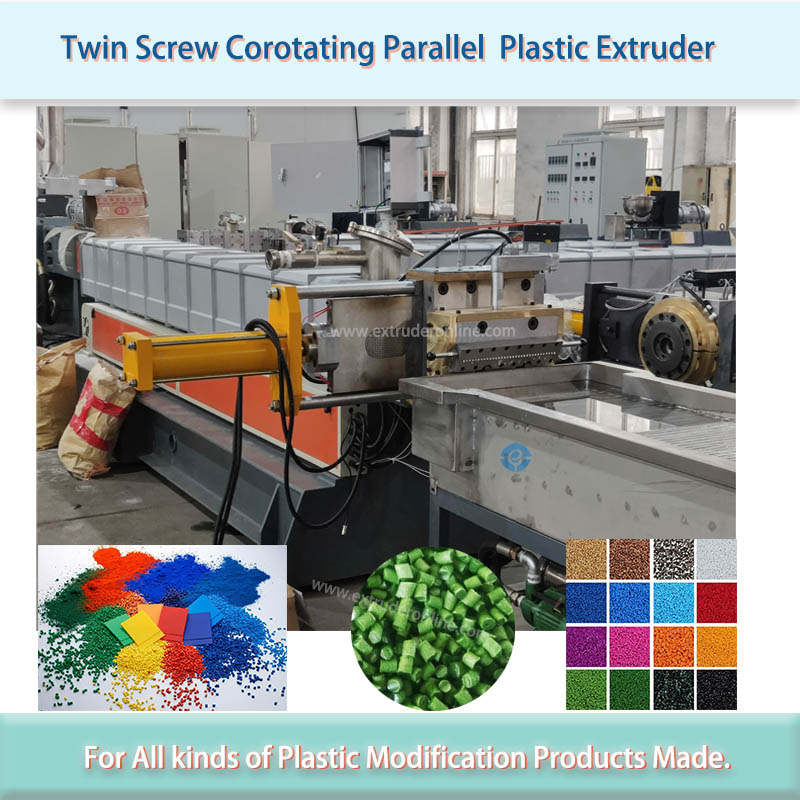

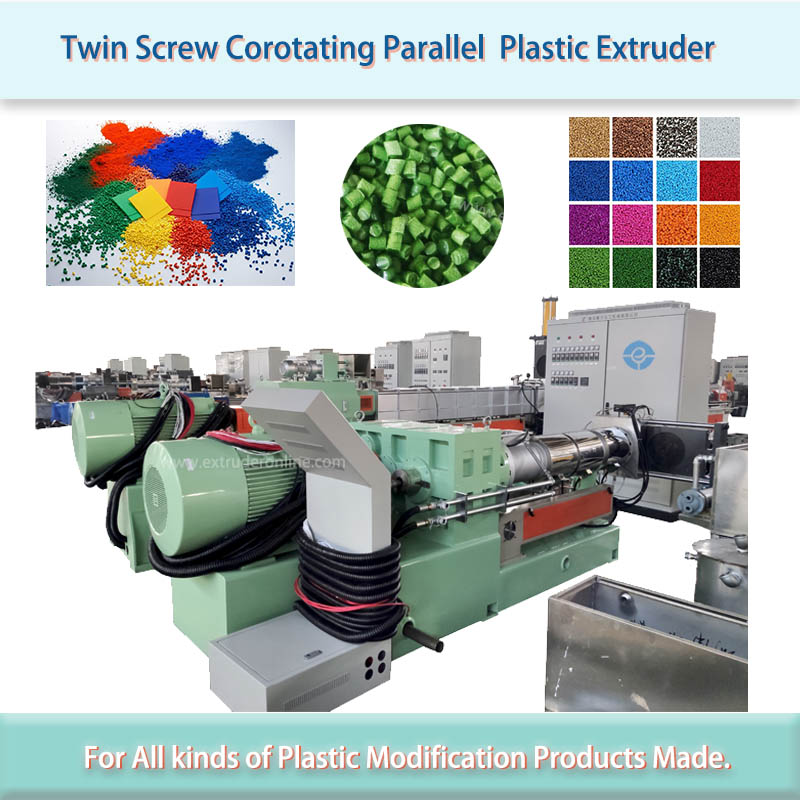

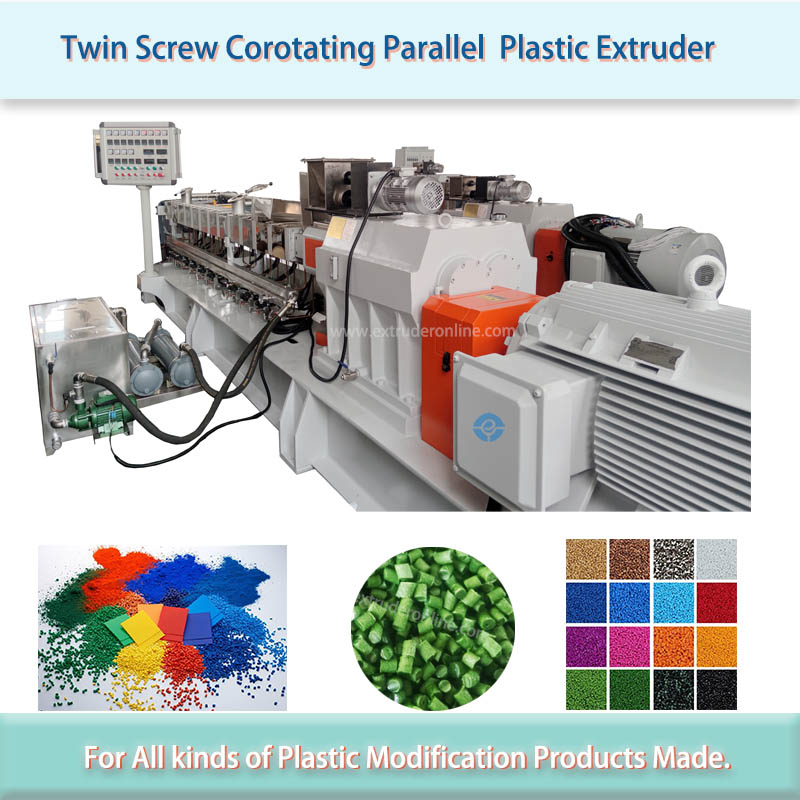

Twin Screw Plastic Extruder 65mm Diameter

65mm Diameter by the barrel's middle hole by the Twin Screw Plastic Extruder , and it belong to the Co-rotating Parallel Twin Screw Plastic Polymer Extruder

HS CODE: 8477.2010.00

This machine line is wild used for many business field, like to say, filler, master batch, engineering granules, bio mass, bio-degradable extrusion, GFL ( glass Fibre added) and other modification plastic business scope.

This machine line has different kind of cutting system:

1) air cooling hot-face cutting system;

2) air cooling belt convoying system;

3) strand bathing water cooled pelletizing system;

4) water-ring cooled hot-face cutting system;

5) under water cutting system;

for its' wild usage, not only for engineer granules making, but also for single color(white, black, red or other single color large output capacity orders.) master batch, functional granules(anti-static, anti-flame, fire retared, anti-UV,anti-aging granules.) production. If you need to produce the Plastic sheet or panel, then just change the die-head when you place the order to us or equipped extra die-head and other auxiliary equipments ( Auxiliary machine, like three rollers calander, dragging machine and others.)

Rough configuration for strand bath water cooled pelletizing system:

L/D ratio:40:1

Screw Dia.: 62.4mm

Barrel hole Dia.: 63mm

Whole hardness: 62-64

Screw Speed: 400/500/600 rpm (optional)

Motor power: 75Kw/90Kw(selection, according to the raw material of carrier),

Motor Brand: Wannan or Siemens-beide brand;

Machine line includs HOST(main machine includs water cooling system for barrels, vacuum system for barrels, oil ilubrication system for gearbox), Power cabinet for HOST, water trough, air knife, pelletizer and some spare parts.

Our machine can process the following materials:

|

Process

|

Representative materials

|

|

Mixing nature-changing

|

PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA +Silicon rubber, etc.

|

|

PE,PA,PC,CPE+ABS(alloy),PBT+PET,PP+ PE etc.

|

|

Filling nature-changing

|

PE,PP,EVA, etc.+ Calcium carbonate, talcum powder, titanic powder

ABS,PC,PS, etc.+ aluminum hydroxide, magnesium hydroxide, antimony oxide.

|

|

PP,PA,ABS +ferrous powder, sulphuric powder ceramic powder

|

|

Functional machine pellets

|

PP,PA,ABS,PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets

|

|

PE,PP,PS, etc+ starch: de-composing machine pellets

|

|

PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets

|

|

PE,EVA=ABS etc+ carbon black: black machine pellets

|

|

Colored machine pellets

|

PE,PP,ABS,AS,PA,EVA,PET +pigment and auxiliary

|

|

Intensified glass fibers and carbon fibers

|

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET etc.+ long fibers, small fibers, carbon fibers, crystals and so on, etc.

|

|

Various cables

|

HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP, etc. insulating cables,coatings,

PE peroxide silicon alkyl crossing cables: radialization crossing cables

|

|

Special materials

|

EVA heat-melting glue, polyurethane, fluorine rubber, fluorine plastics, PP cigarette filtering material and TPR sole material

|

|

Reaction extruding

|

Poly-amide condensate, poly-amide melting polymerization, poly-amide polythene-adding, poly-carbonate condensate, etc.

|

|

Exhausting and volatilization

|

Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene

|

|

Powder paint

|

Polyester, ring oxide, lactide, polyurethane, acrylate

|

Production Standard: Export Standard

Packing: Export standard packages

1) FCL: Metal frame on the bottom for transportation by lift when loading or unloading into/from the container to workshop; wrap film cover whole machine and parts; if it has meter or PLC outside, then will pack it carefully avoide crush.

2) LCL: Wooden case for package, but we will charge the packing cost to the clients.

Minimum order: 1unit/order placed by one time;

Quality Guarantee: 1 year from B/L issued date, except quick-ware parts (like segments, heaters, shafts, sensor and Etc., we will list them on delivery packing list; We will collect the cost of the replace parts if the problem by man-made damage.

Installation and debugging charges: will be collected, please ask for our clerks in overseas markets department.

Documents presentation: B/L, INVOICE, PACKINGLIST, C/O and Insurance policy (If CIF terms);

We can also present the following machine lines, Technical Parameter is as follows:

|

Model

(A/B/D/G)

|

Screw Dia.

(mm)

|

Screw Rotary

Speed (rpm)

|

Motor Power

(kw)

|

L/D

|

Output Capacity

(kg/h)

|

|

SHJ-20

|

21.7

|

600

|

4

|

32-60

|

0.5-15

|

|

SHJ-35

|

35.6

|

500

|

11-15

|

32-60

|

15-40

|

|

SHJ-50

|

50.5

|

500

|

45/55/75

|

32-60

|

135-225

|

|

SHJ-65

|

62.4

|

500/600

|

55-75-90

|

32-60

|

25-375

|

|

SHJ-75

|

71.0

|

500-600

|

90/110/132

|

32-60

|

330-550

|

|

SHJ-95

|

93.0

|

400-500

|

250/315

|

32-60

|

750-1250

|

Field of application:

SHJ series co-rotating twin screw extruders are mainly applied in polymer processing. To meet the increasingly demand from new materials and process, our company has been providing more new technologies and products accordingly.

Filling modification Cables & Wires

Powder-coating Blending

Degassing Reinforcing modification

Master-batch preparation Reactive Extrusion

Other Applications

New Mixing & Extrusion Elements (segments)

The SHJ series extruders have newly developed screw elements (segments) for good distributive and dispersive mixing and extrusion process. The special screw elements will be greatly conductive to the even shearing stress, even axial elongation rate, and low temperature distribution. All these factors will determinately lead to the final material or products’ quality.

The SHJ series extruders have unique features with a balanced shaft drive mechanism, a solution offering decisive advantages over the conventional gearing chain with a simple split of the driving torque. In the new solution the torque for the second screw is split again in half to drive two auxiliary shafts at levels above and below the second screw shank. Consequently the balanced gearing shafts have to bear the 25% torque of the overall. The extreme load ability connected with this type of gearing chain enable to work with the kind of torques required to achieve high output rates at lower screw speeds that will be decisive to the final performance of the mixing polymer.

Both screws and barrels are designed according to the principle of building block type. Let the machine line has excellent dispersion, mixing and compounding performance, controllable material duration of staying time in the barrels. In the meantime, this design also has good exhaust release performance, excellent interchangeability, self-cleaning, flexible module combination and other characteristics, to achieve a wide range of muti-function, multi-purpose and specific requirements of the specific unity。