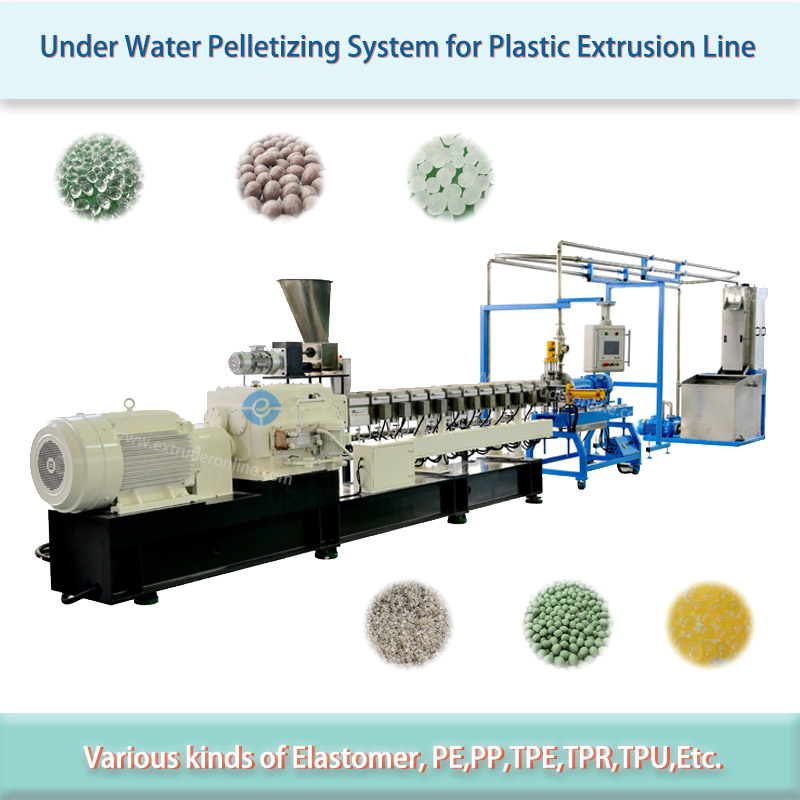

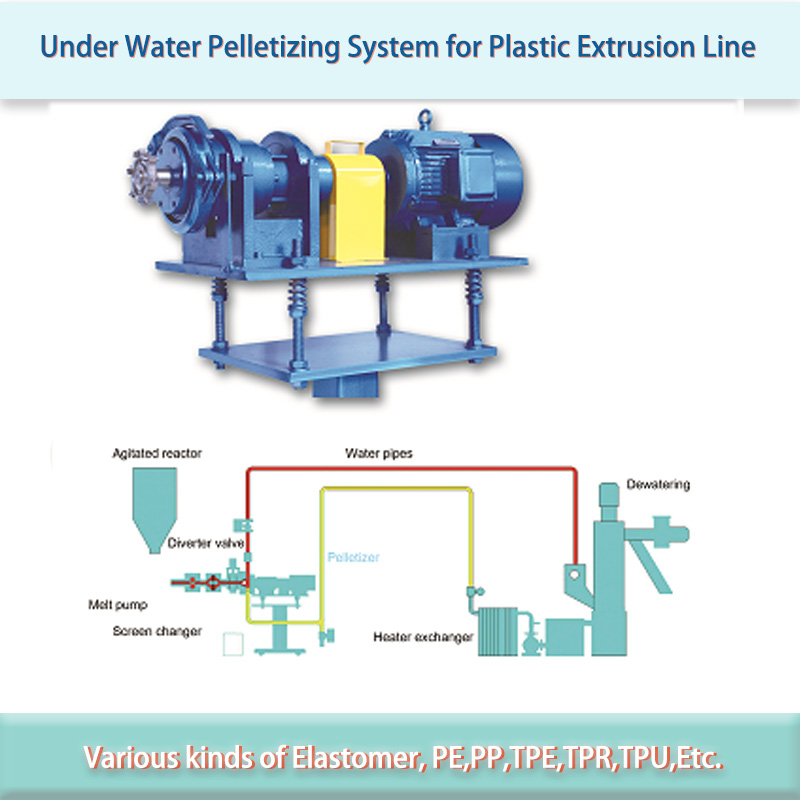

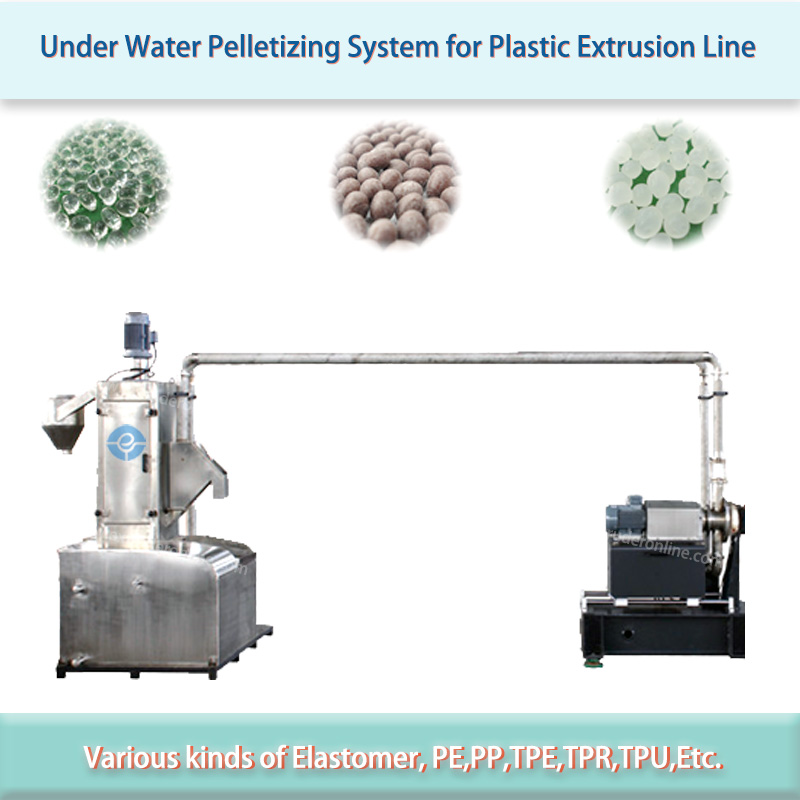

Underwater Pelletizing system for Twin screw Plastic Extruder

Model: 300/500/800/1000 for various kind of twin screw or three screws(shafts) extrusion machine.

HS CODE: 8477.2010

Such kind of machine is special for elastomer plastic rubber making according to the clients' detailed request.

We have various of models for different kind of output capacity, the smallest one is that for labortoury to double check the formula is workable or the technical processing is right. The largest one is that the SHJ-95, for 95 twin screw plastic extruder, we also have differnt model: SHJ-95A, SHJ-95B, SHJ-95C,SHJ-95D and SHJ-95G.

For plastic elastmer under water pelletizing making, if you need large output capacity, you can select our large output capacity model: 800 or 1000, it means 800Kgs/h or 1000kgs/h for output.

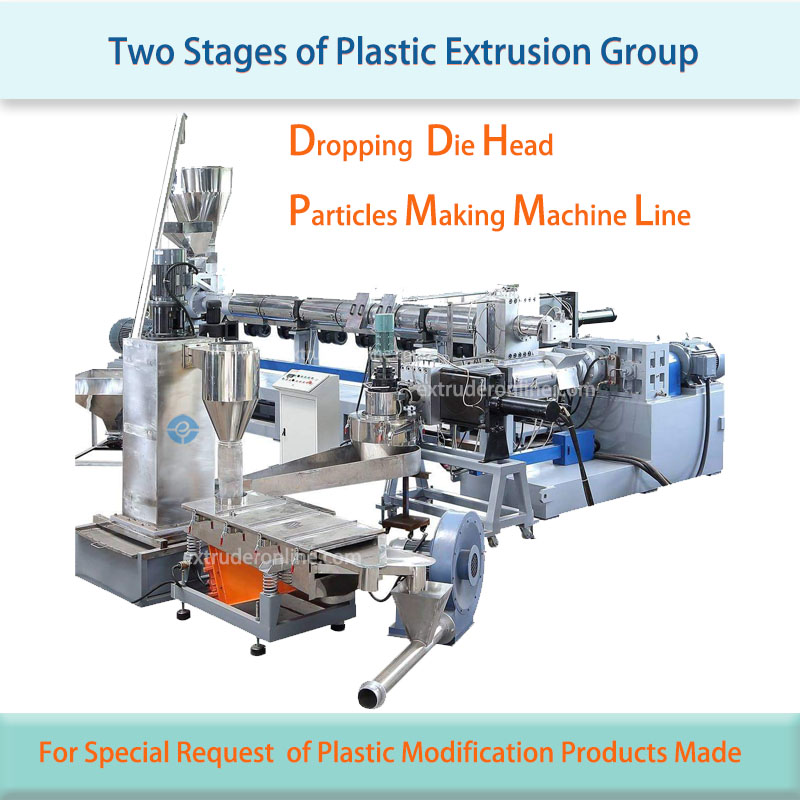

We also made other pelletizing method machine for the plastic extruders.

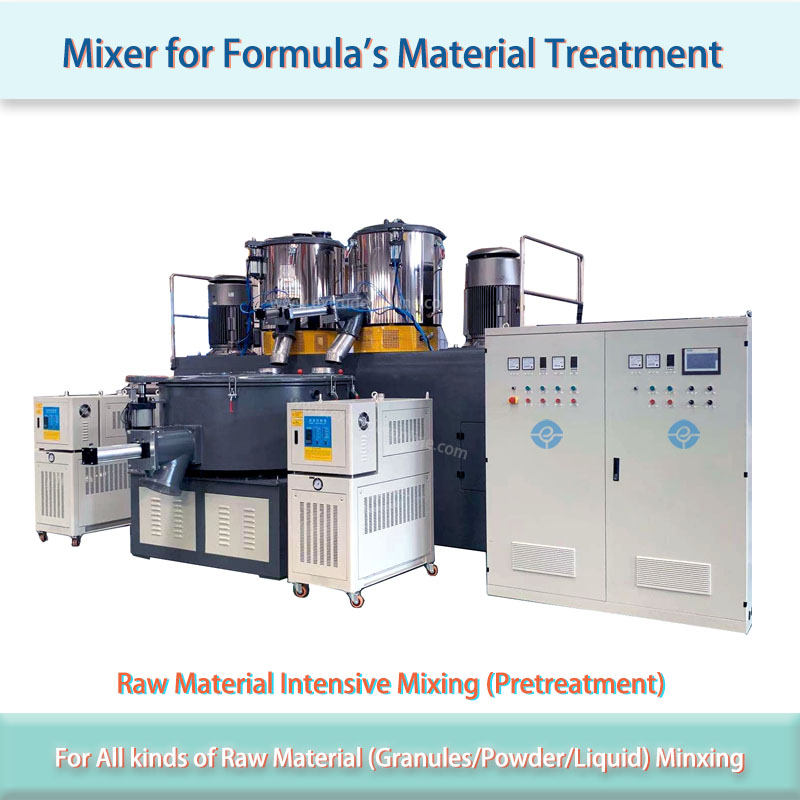

Anyway, for such plastic extrusion machine line set, you have to set a pretreatment machine for them: plastic mixer.

The plastic mixer have different kind of , like to say color pigment mixer, high speed mixer, corn starch powder two stage mixing group and so on.

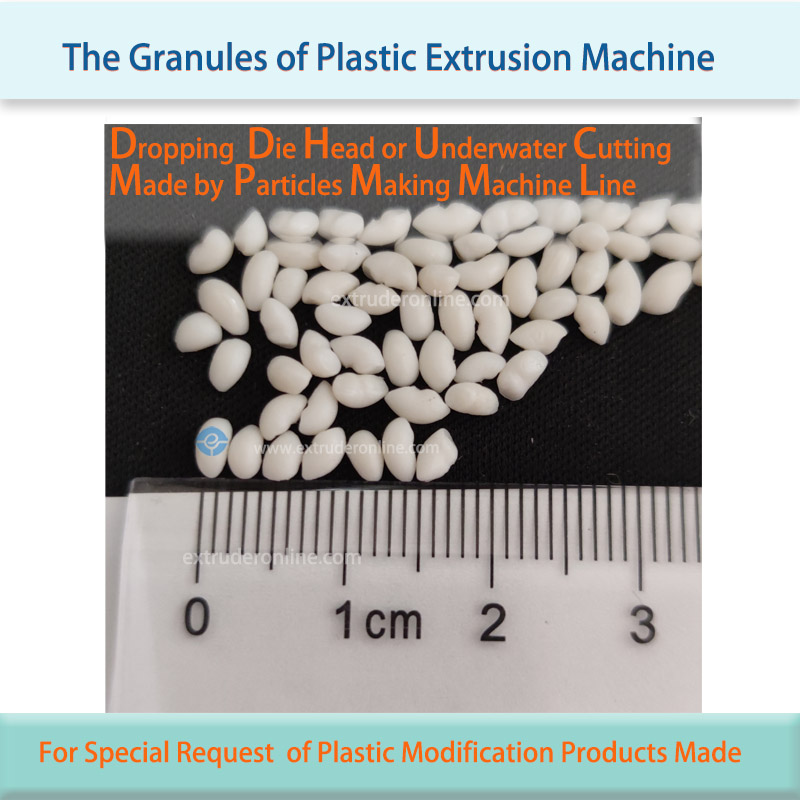

In the meantime, if you select the different kind of the die head and pelletizing system, you will get the plastic granules or particles by your special demads.

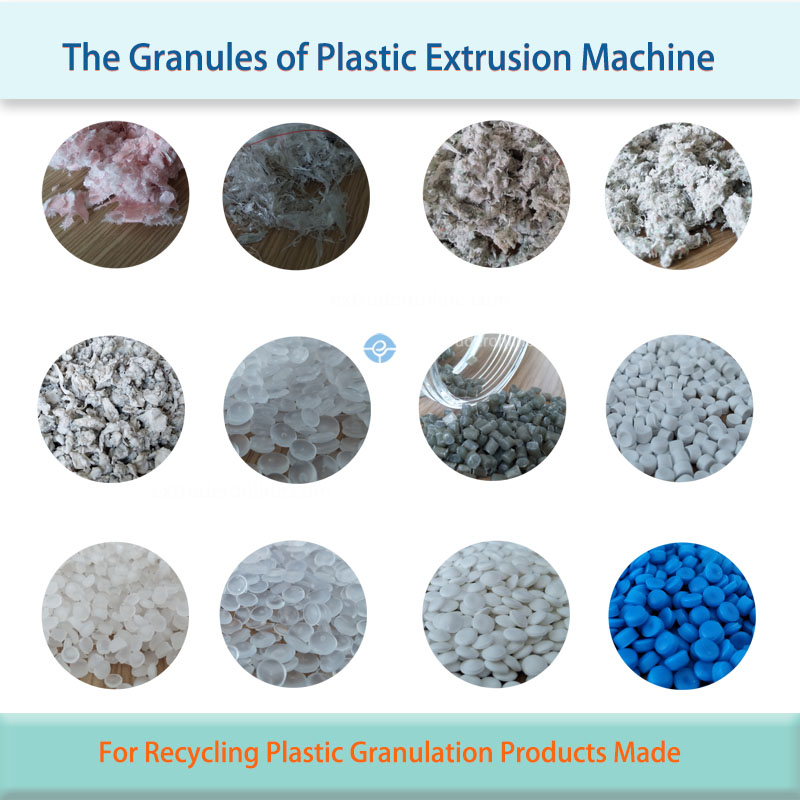

Other pelletizing method treated granules:

Installation and debugging charges: will be collected, please ask for our clerks in overseas markets department.

Documents presentation: B/L, INVOICE, PACKINGLIST, C/O and Insurance policy (If CIF terms);

We also present the following SHJ series plastic extrusion machine, the detailed technical parameter is as follows:

|

Model

|

Screw Dia.

(mm)

|

Screw Rotary

Speed (rpm)

|

Motor Power

(kw)

|

L/D

|

Output Capacity

(kg/h)

|

|

SHJ-20

|

21.7

|

600

|

4

|

32-60

|

0.5-15

|

|

SHJ-35

|

35.6

|

500

|

11-15

|

32-60

|

15-40

|

|

SHJ-50

|

50.5

|

500

|

45/55/75

|

32-60

|

135-225

|

|

SHJ-65

|

62.4

|

500/600

|

55-75-90

|

32-60

|

25-375

|

|

SHJ-75

|

71.0

|

500-600

|

90/110/132

|

32-60

|

330-550

|

|

SHJ-95

|

93.0

|

400-500

|

250/315

|

32-60

|

750-1250

|

Both screws and barrels are designed according to the principle of building block type. Let the machine line has excellent dispersion, mixing and compounding performance, controllable material duration of staying time in the barrels. In the meantime, this design also has good exhaust release performance, excellent interchangeability, self-cleaning, flexible module combination and other characteristics, to achieve a wide range of muti-function, multi-purpose and specific requirements of the specific unity。

New Mixing & Extrusion Elements (segments)

The SHJ series extruders have newly developed screw elements (segments) for good distributive and dispersive mixing and extrusion process. The special screw elements will be greatly conductive to the even shearing stress, even axial elongation rate, and low temperature distribution. All these factors will determinately lead to the final material or products’ quality.

The SHJ series extruders have unique features with a balanced shaft drive mechanism, a solution offering decisive advantages over the conventional gearing chain with a simple split of the driving torque. In the new solution the torque for the second screw is split again in half to drive two auxiliary shafts at levels above and below the second screw shank. Consequently the balanced gearing shafts have to bear the 25% torque of the overall. The extreme load ability connected with this type of gearing chain enable to work with the kind of torques required to achieve high output rates at lower screw speeds that will be decisive to the final performance of the mixing polymer.