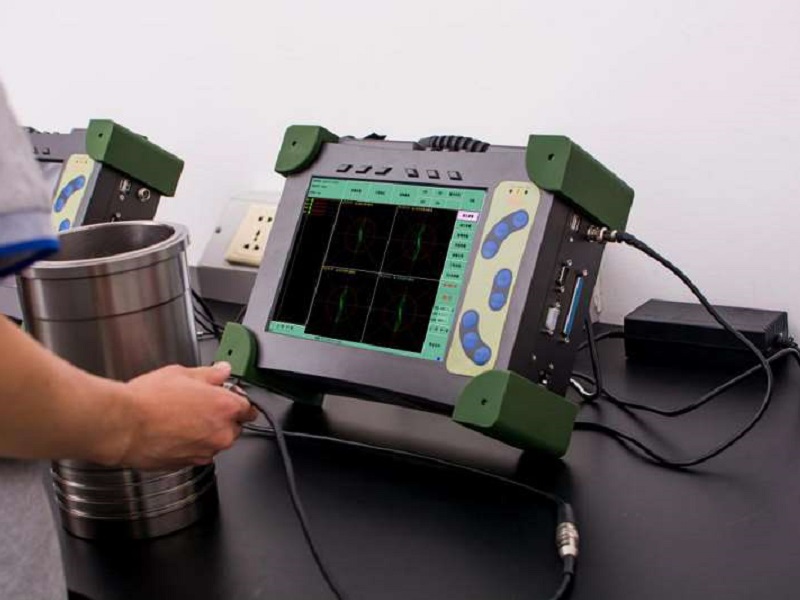

V-P5D-ET Intelligent Multi-frequency Eddy Current Detector adopts the most advanced microelectronic digital processing technology, real-time multi-frequency eddy current detection & microprocessor technology, which can effectively real-time detect the defects of metal components, distinguish alloy types & heat treatment condition. The detector realizes human-machine interaction, screen menu prompt, is easy to operate. Parameters and expert procedures can be preset according to the user's needs.

Functional Information

· Multi-frequency&Multi-channel eddy current detecting

· Fast High Precision/Digital Electronic Balance

· The excitation amplitude of the probe can be adjusted

· Displaying Dual Impedance Plane Graph& Time Based Scan Graph

· Built-in high-performance solid-state lithium battery can work continuously for more than 8 hours.

· Interfaces: U port, network port and encoder interface

· 10.4 "TFT LCD Display with High Resolution

· Having Multiple filtering methods

· Special process parameters can be preset

· Having various storage methods.

· Having unique function of crack sounding

· Having Detection waveform recording/playback function

· Having simple operation with Chinese&English operation interface.

Technical Parameters

|

USB port

|

2

|

|

RS232 port

|

1

|

|

video output

|

Standard VGA output

|

|

Alarm output

|

8

|

|

Start input

|

8

|

|

Coder input

|

1

|

|

Work Temp.

|

–10°C~50°C

|

|

Relative Humidity

|

Not over 80%

|

|

Size

|

W 320 mm * H 235 mm * T 103 mm

|

|

Weight

|

3kg, Li-battery included

|

|

Language

|

English / Chinese

|

|

Data Storage

|

30GB

|

|

Battery ON time

|

8hours

|

|

Power supply

|

AC:200 VAC ~ 240 VAC,50 Hz ~ 60 Hz

|

|

Adapter:

|

DC15.6V,6A

|

|

Monitor

|

10.4” Screen

|

|

Detection Channel

|

1~4

|

|

Probe frequency

|

10 Hz ~ 10MHz,Increment 1Hz

|

|

Probe drive

|

1~16 classes

|

|

Hardware gain

|

0~40dB,min step 0.1dB

|

|

Software gain

|

0~99dB,min step 0.1dB

|

|

Phase rotation

|

0~359°, min Step 1°

|

|

Display mode

|

full line, blanking

|

|

Detection

|

Full wave, positive half wave, negative half wave, radio frequency wave

|

|

Filter factor

|

0~4000

|

|

Alarm window

|

Sector, rectangle, negative circle

|

|

Filter

|

Grade 3 Filter

|

Application Areas

· For general defect evaluation (surface inspection of aircraft components such as blades, hubs, landing gears, etc.)

· For rivet holes or bolt holes, cracks on the inner surface of the holes can be detected without removing or detaching fasteners.

· Detection of Surface Cracks on Various Metal Parts and Welds

· Detection of in-service copper, titanium, aluminum, zirconium and other non-ferromagnetic heat exchanger tubes

· Detection of interlayer gap corrosion of composite materials, such as detection of multilayer structures of aircraft, aluminum skin and fuselage wing joints, etc.

· Monitoring the change of heat treatment state and sorting materials

· With additional functions of weld seam detection with anticorrosive coating, crack depth measurement and conductivity measurement (optional), the instrument is especially suitable for in-service and pre-service detection in the fields of aviation, aerospace, electric power, petrochemical and mechanical manufacturing, etc.