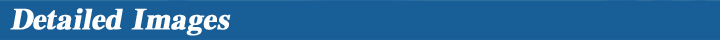

Vacuum Electrode Thin Film Coater Coating Machine With Vacuum Chuck and Dryer

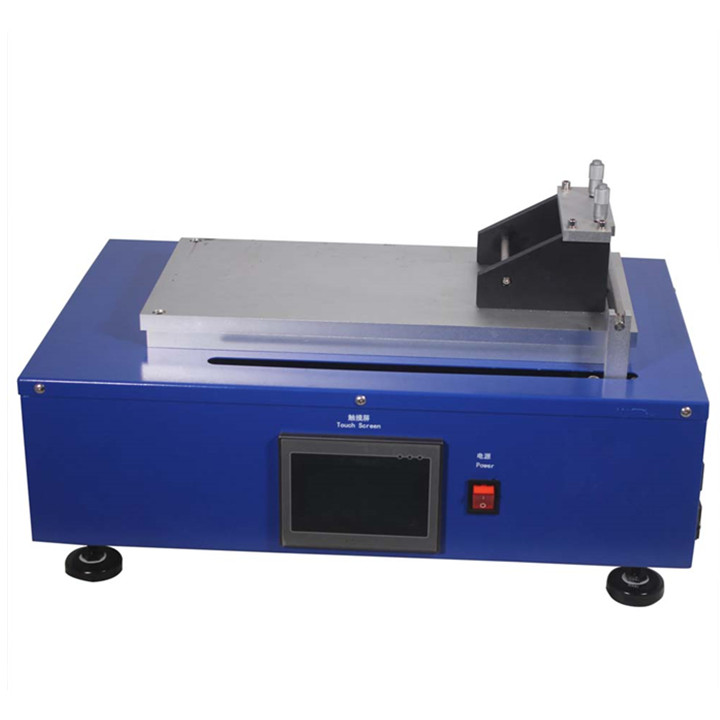

TMAX-TMH is a CE Certified ready compact tape casting coater with a heating cover designed to produce films with consistent thickness. It has a unique driving system to produce a smooth coating on all types of materials. The flat vacuum chuck is built in to hold the substrate sheet in place, which is particularly useful when making thin coatings. There is a 100 mm width adjustable micrometer applicator (doctor-blade).

Heating cover with digital temperature controller can dry films after coating up to 100°C with a temperature accuracy of +/-1°C. This equipment can be used for researchers on ceramic tape castings and Li-Ion battery electrode coating. We are committed to providing high quality vacuum coating machine for you!

|

Model

|

TMH250

|

TMH300

|

TMH350

|

TMH550

|

TMH800

|

TMHXXX

|

|

Effective Coating Size

|

100*250mm

|

200*300mm

|

250*350mm

|

250*550mm

|

250*800mm

|

customized

|

|

Machine Weight

|

80kg

|

100kg

|

115kg

|

130kg

|

160kg

|

N/A

|

|

Accessories: Film Applicator

|

Optional 50 up to 300 mm width micrometer film applicator is included

Or customized

|

|

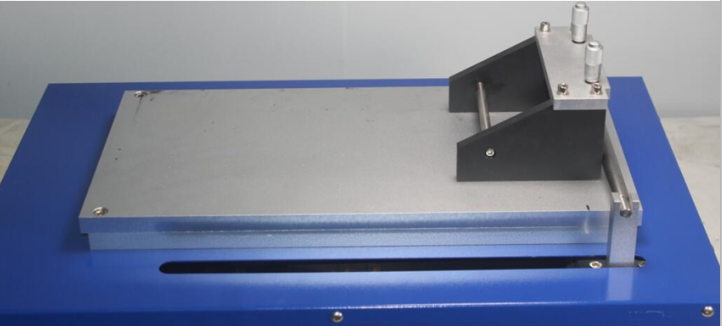

Optional Heating Cover Voltage and Power

|

110VAC or 220VAC

|

|

Traverse Speed

|

0 - 120 mm/sec variable

Accuracy: 10mm/sec

|

|

Vacuum Pump

|

Vacuum pump is included

|

|

Heating Cover

|

1. Pre-installed on the top cover

2. Built in digital temperature controller with accuracy of +/-1°C

3. Suspension support helps open cover easily and safely

4. Max. Heating Temp: 200°C

|

|

Compliance

|

CE Certificate

|

|

Warranty

|

Two years limited warranty with lifetime support

|

|

Operating procedures

|

1. Put the Electrode on the vacuum plate, start the power supply, open the vacuum, the electrode adsorption on the vacuum plate.

2. Place the film applicator on the electrode and add the coating slurry.

3. Open the film, the film device automatically pushes the film applicator to move, automatic film.

4. Take out the film applicator and push rod, cover with the heating cap, set the heating temperature and time, and heat and dry.

5. After drying, open the heat cover, take out the coated film electrode, film device reset complete.

|

|

Maintenance method and matters needing attention

|

1. Every time before work to use a soft cloth with alcohol carefully wipe the film head, the body, keep clean.

2. Film head, differentiator and other high-precision parts of the use do not collide, gently take gently, differentiator to adjust the left and right to be symmetrical and even.

3. Regularly check screws, nuts, pins and other fasteners in various parts to prevent looseness and prevent product quality accidents.

|