|

Stone

Type

|

Artificial Quartz Stone

|

|

Iteml

No

|

SS6141-Shadow

|

|

Size

|

a)-Slabs size: 3000x1400mm,3000x1600mm, 3200x1400mm, 3200x1600mm etc.b)-Cut-to-size:

1200 x 1200 mm, 800 x 800 mm, 1200 x 800 mm, 600 x 600

mm, 300 x 300 mm, 300 x 600 mm and can be customized as per your

require.

c)-Counter top: 48*26". 70*26", 78*26", 96"x 26",

108"x 26"

d)-Island: 72"x 36", 96"x 36", 96"x 40",

108"x 44"

e)-Vanity top: 22"x 25", 22"x 31", 22"x 37",

22"x 49", 22"x 61", 22"x 73"

|

|

Thickness

|

12 mm, 15 mm, 18

mm, 20 mm, 30 mm

|

|

Thickness

tolerance

|

±1mm

|

|

flexural

Strength

|

25~35 Mpa

|

|

Sample

size

|

80*60*15mm,100*100*15mm

|

|

Ideal

Use

|

Kitchen counter tops, worktops,

island tops,bar tops, wall tile, etc.

|

|

MOQ

|

100square Meter

|

|

Quality standard

|

We have our own

professional QC team to insurance the quality of course its our pleasure to

welcome your QC team to check quality in our factory

|

|

Package

|

a)-Slabs: 15-20pcs pack

in a seaworth bundle (after funmigation)

b)-Cut-to-size: 60-80pcs

pack in a seaworth crates (after funmigation)

c)-Countertop, Vanity

top: 12 - 25pcs pack in a seaworth crates, each surface cover with PE film

(after fumiation)

|

The hottest new trend

in kitchen design is quartz stone countertops. Quartz is now the countertop style of

choice for most homeowners designing their dream kitchen. And while quartz slab

comes in a range of beautiful finishes and colors, this countertop material’s newfound popularity

isn’t just about looks. The quartz countertop material is compressed into slabs

that have similar color and texture to natural granite and marble. One

difference you’ll notice is that the color is more uniform than the variations

in hue you’ll find in most slabs of natural stone. Quartz can fit practically

any style.It also comes in a wide range of colors, unlike granite, which can be

more limited due to the natural process from which it is made.

Quartz is heat and scratch resistant., but it is not

recommended that hot pots and pans be placed directly onto quartz surfaces.

Quartz can be affected by extreme heat, so it is best if you use cutting boards

and hot pads in order to protect your stone.

The high quartz content in quartz countertops makes it harder, stronger

and more stain resistant than granite. Unlike granite, quartz countertops does

not need sealing.

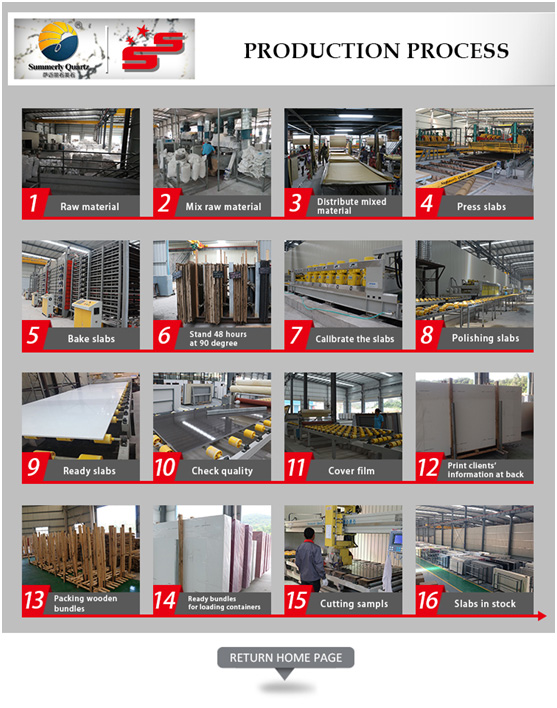

Production Engineering:

1. The process begin with a rigorous inspection

of raw materials.

2. Feeding natural quartz raw material and

polymer resins and inorganic pigments in to mixers and blending them together.

3. After stirring the mixture, then pouring

them into a mold and form them into slab size.

4. Pressing: Then the slab is compacted by a

special vacuum and vibration process at pressure machine.

5. The slab then moved to the curing kiln and

heated for a period time which give them ultimate strength and solidity.

6. Trimming edges, leveling , thicknessing and

polishing surface to perfect finished.

7.Finally, the quartz stone slabs passed

through quality inspection and packed with a plastic film.

Packing wooden

crate (slab) wooden box (tiles/

countertop)