Wooden grain coated aluminum coils are widely applied to ACP,

aluminum ceiling, roofing, fireproof roller shutter, doors, wall panel , facade cladding, etc.

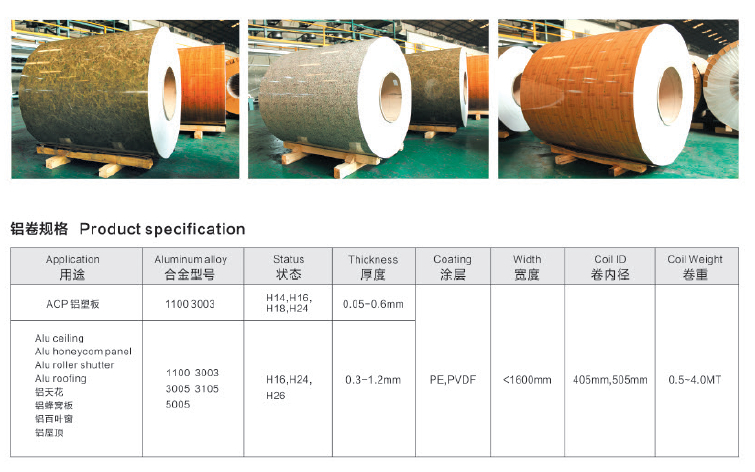

1. Specification for coated aluminum coils

01)Material: aluminum alloy A1100, A3003, A3005, A3105

02)Aluminum thickness:0.04-1.20mm

03)Max coil width: 1600mm(standard 1240mm)

04)Coil ID: 405mm,505mm, Coil OD: 1000-1400mm

05) Coil standard weight: 2500kgs/coil

06) Coating: PE or PVDF coating

07) Surface treatment: anti-scratch, glossy, matte

08) Color: wooden grain, marble stone, plain color,3D, HD, metallic, patterned, etc.

09) Dried and baked: oven baked at 450 degree F

10) Coating thickness: double coating-25 micron, single coating-18 micron

11) Coating hardness: (pencil hardness) 2H

12) Coating adhesive: no lower than first grade

13) Impact resistance: no cracking and peeling(50kg/cm, ASTMD-2794:1993)

14)Flexibility(T-bend):2T or by your option

15) MEK resistance: more than 100

16)Outer packing: wooden plate, covering with craft paper and film, Eye to Sky or wall to Sky packing.

2. Applications

Interior applications: ACP skin, door skin, wall cladding, ceilings, kitchen cabinet, balconies, shutters...

Exterior applications: roller shutters, gutters, wall cladding, facades, roofing, canopies, tunnels, column covers , renovations...

Advertisement and market applications: display platforms, signboards, fascia, shop fronts...

| Coating Characteristic table |

| Item |

Test Item |

Standard |

National standard |

DF Test Result |

| 1 |

Color Difference |

ECCA T3 |

Δ E≤ 2.0 |

Δ E≤ 1.5 |

| 2 |

Gloss Difference |

ECCA T2 |

≤ 10 |

≤ 5 |

| 3 |

Coating Thickness |

ECCA T1 |

Two layers Min 23um |

≥ 24um |

| |

|

|

Three layers Min 30um |

≥ 33um |

| 4 |

Pencil Hardness |

ASTM D3363 |

≥ HB |

HB |

| 5 |

T-bend |

ASTM D4145 |

≤ 2T |

≤ 2T |

| 6 |

Adhesion |

ASTM D3359 |

Grade 0 |

Grade 0 |

| 7 |

Impact |

ASTM D2794 |

≥ 50 kg/cm |

≥ 50 kg/cm |

| 8 |

Boiling water Resistance |

GB/T17748 |

2h No Change |

4h No Change |

| 9 |

Solvent Resistance |

ASTM D2248 |

200 times paints remaining |

500 times no break |

| 10 |

Acidity Resistance |

ASTM D1308 |

5%HCL 24hrs no change |

No change |

| 11 |

Alkali Resistance |

ASTM D1308 |

5%NaOH 24hrs no change color Δ E≤ 2.0 |

No change |

| 12 |

Nitric acid Resistance |

AAMA620 |

Δ E≤ 5.0 |

Δ E≤ 5.0 |

| 13 |

Oil Resistance |

ASTM D1308 |

20# oil 24hrs no change |

No change |

| 14 |

Salt Spray Resistance |

ASTM B117 |

4000hrs≤ Grade 1 |

No change |

| 15 |

Abrasion resistance |

ASTM D968 |

≥ 5L/um |

≥ 5L/um |

| 16 |

Dirt Resistance |

GB/T9780 |

≤ 5% |

< 5% |

| 17 |

Color retaining |

GB/T16259 |

4000 hrsΔ E≤ 4.0 |

4000 hrsΔ E≤ 3.0 |

| 18 |

Gloss weaken Level |

GB/T16259 |

4000 hrs ≤ Grade 2 |

4000 hrs ≤ Grade 2 |