What is 3D Printing

3D printing is a manufacturing process that creates three-dimensional objects by building layers of material based on a digital model or design. It involves the use of computer-aided design (CAD) software to create a 3D model that is then translated into a series of 2D cross-sectional layers. These layers are then printed one on top of the other to create a physical object. 3D printing can use various materials, including plastics, metals, and even food or living cells. It has various applications in industries such as aerospace, automotive, healthcare, and consumer goods.

Our 3D Printing Solutions

Comely CNC specializes in industrial 3D printing services, with a focus on direct metal laser sintering (DMLS), fused deposition modeling (FDM), selective laser sintering (SLS), and stereolithography (SLA).

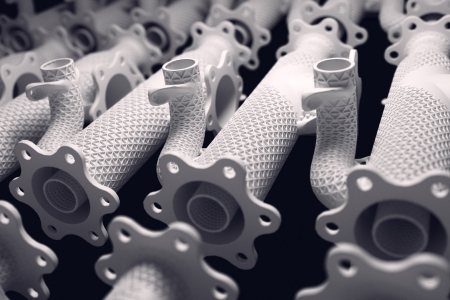

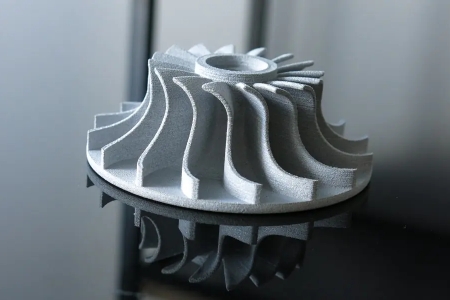

• DMLS and SLM

They use a fiber-laser system and atomized powder to create fully functional metal parts for industries such as automotive, aerospace, and medical. While SLS isn't used for metallic parts, DMLS and SLM can produce parts from single-element materials and metal alloys.

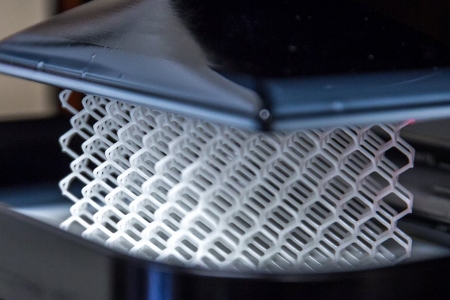

• FDM

FDM is widely used for design validation and low-volume production, using affordable plastic filaments to create parts for idea validation and quick prototyping. However, FDM parts may not have tight tolerances and excellent surface texture post-print.

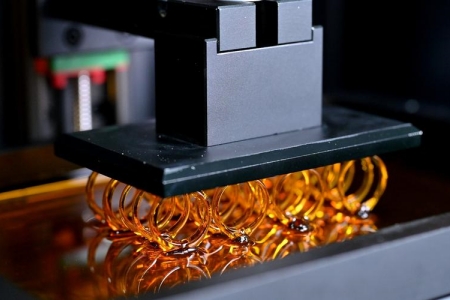

•SLA

SLA is a 3D printing technique that uses a UV laser to cure liquid thermoset resin and form production-grade parts, making it ideal for projects where visual appeal is crucial and injection mold-like finishes are desired.

•SLS

SLS is used to create finely fused thermoplastic parts that have excellent mechanical and functional attributes. The process involves directing a laser, acting as a power source, towards powdered material at points dictated by the 3D CAD model.

Why You Should Choose 3D Printing

• Customization:

With 3D printing, you can easily customize your products or parts to meet specific needs and requirements. You can adjust designs and dimensions to create a unique, one-of-a-kind product.

• Cost-effective:

3D printing can be a cost-effective manufacturing option, particularly for low-volume production runs. It eliminates the need for expensive tooling and molds that are required in traditional manufacturing methods.

• Faster production:

3D printing can significantly reduce the time it takes to produce a part or product, especially when compared to traditional manufacturing methods.

• Reduced waste:

Since 3D printing is an additive process, it only uses the necessary amount of material required to build the part or product, reducing waste and making it an environmentally friendly manufacturing method.

• Design flexibility:

With 3D printing, there are fewer design limitations, allowing for more complex and intricate designs to be created that may not be possible with traditional manufacturing methods.

Applications of 3D Printing

3D printing has numerous applications across various fields, some of which are:

• Prototyping:

Rapid prototyping is made possible with 3D printing, an essential tool for developing and testing new products.

• Manufacturing:

3D printing finds its application in low-volume manufacturing where it is used to produce customized products and replacement parts.

• Healthcare:

The medical industry uses 3D printing to create custom implants, prosthetics, and surgical tools, revolutionizing healthcare.

• Aerospace:

The aerospace industry utilizes 3D printing to create intricate and lightweight parts for spacecraft and aircraft.

• Automotive:

In the automotive industry, 3D printing is used for prototyping, customized parts, and tooling, bringing efficiency and accuracy.

• Education:

Schools and universities incorporate 3D printing to impart design and engineering skills to their students.

• Architecture:

Architects use 3D printing to create complex models and prototypes of buildings, augmenting their design process.

• Art and Design:

3D printing is a popular choice for artists and designers, who use it to create unique sculptures, jewelry, and other works of art.

• Food:

The food industry utilizes 3D printing to create intricate designs and shapes, such as chocolate and cake decorations, enhancing their presentation.

• Fashion:

The fashion industry uses 3D printing to create personalized accessories and unique designs, giving their creations an edge.

3D Printing Materials

Here are some of the most common 3D printing materials:

• PLA (Polylactic Acid) - a biodegradable and compostable thermoplastic that is easy to print and commonly used in consumer 3D printing.

• ABS (Acrylonitrile Butadiene Styrene) - a strong and durable thermoplastic that is often used for functional parts.

• PET (Polyethylene Terephthalate) - a strong and lightweight thermoplastic that is commonly used in the production of bottles, containers, and packaging.

• Nylon - a strong and flexible thermoplastic that is commonly used in the production of gears, hinges, and other mechanical parts.

• TPU (Thermoplastic Polyurethane) - a flexible and rubber-like material that is commonly used for phone cases, shoe soles, and other flexible products.

• Metal - a range of metals can be 3D printed, including stainless steel, titanium, and aluminum. These materials are commonly used in the aerospace, medical, and automotive industries.

• Wood - a material that can be 3D printed using a blend of wood particles and plastic. It is commonly used for creating decorative objects.

• Carbon Fiber - is a lightweight and strong material that is commonly used in the production of racing car parts, bicycles, and aerospace components.

Finishing options

After 3D printing, there are various finishing options available to improve the appearance and functionality of the final printed object. Here are some common finishing options for 3D-printed parts:

• Sanding:

Sanding is a process of smoothing the surface of the printed object using sandpaper or abrasive pads. This process is used to remove layer lines and any imperfections present on the surface.

• Painting:

Painting is a common finishing option used to enhance the appearance of a 3D printed object. It can be done using spray paint, brush-on paint, or airbrush.

• Polishing:

Polishing is the process of smoothing the surface of the object using polishing compounds or machines. It can give the object a glossy finish.

• Vapor smoothing:

Vapor smoothing involves exposing the printed object to a chemical vapor that dissolves and smoothes the surface of the object. This process is commonly used for parts printed with ABS or other thermoplastics.

• Plating:

Plating is a process where a thin layer of metal is deposited onto the surface of the printed object. It can improve the appearance, strength, and durability of the part.

• Texturing:

Texturing is the process of adding patterns or textures to the surface of the printed object. This can be done using specialized printers, texture rollers, or other tools.

• Assembly:

Assembly involves combining multiple printed parts to create a more complex object. This can be done using glue, screws, or other fasteners.

Why Choose Us

• Streamlined process flow

At Comely CNC, our 3D printing operations follow a dedicated process flow that minimizes risk, verifies raw materials, and ensures the production of high-quality prototypes and end parts consistently.

• Scalable and consistent manufacturing

Our additive manufacturing solutions prioritize scalability and repeatability, providing you with the flexibility to prototype or manufacture according to your budget without compromising print quality.

• Comprehensive finishing services

In addition to our precision printing capabilities, we also offer post-printing finishing solutions to enhance the aesthetic appeal of your parts. Our in-house finishing services are subject to the same stringent quality control measures for a lasting guarantee of quality.

• Quick turnaround

Leverage our industrial-grade 3D printers to accelerate your product development cycles and hasten your time-to-market. With our expertise, we can help you overcome bottlenecks and fast-track your product development right away.

3D printing FAQs

1. What is the maximum printable size?

Our current maximum printable size is 800x600x400mm, but please note that larger sizes may result in decreased precision.

2. What is the thinnest wall thickness you can print?

Our minimum achievable wall thickness is 1mm.

3. How strong are the printed units?

We evaluate each part for its size and required strength to determine if it is suitable for 3D printing. If a part is not suitable, we inform our clients.

4. Can you achieve high precision in printed parts?

3D printing is inherently less precise than CNC machining. For high-precision parts, we recommend CNC machining.

5. Which parts are suitable for 3D printing?

Parts that require lower precision and are used for fit or concept validation are ideal candidates for 3D printing.