5 Layer Co-extrusion OBSTRUCTIVE FILM BLOWING MACHINE

The barrier layer in the 5-layer structure is usually in the core, which is isolated from the moisture in the atmosphere. Because the barrier layer is in the core, other materials can be used to substantially enhance the barrier properties. Also you can add color on the outer layer, which is without affecting the tie layer or the barrier layer.

Compare to the 3layers film, 5-layer structure, it is more common to use a symmetrical or near-symmetric structure to reduce curl. In a 5-layer structure, the processor can utilize nylon 6 to make it possible to obtain a nylon layer that is approximately half the thickness of the 3-layer film. This saves raw material costs while providing the same barrier properties and improved processability

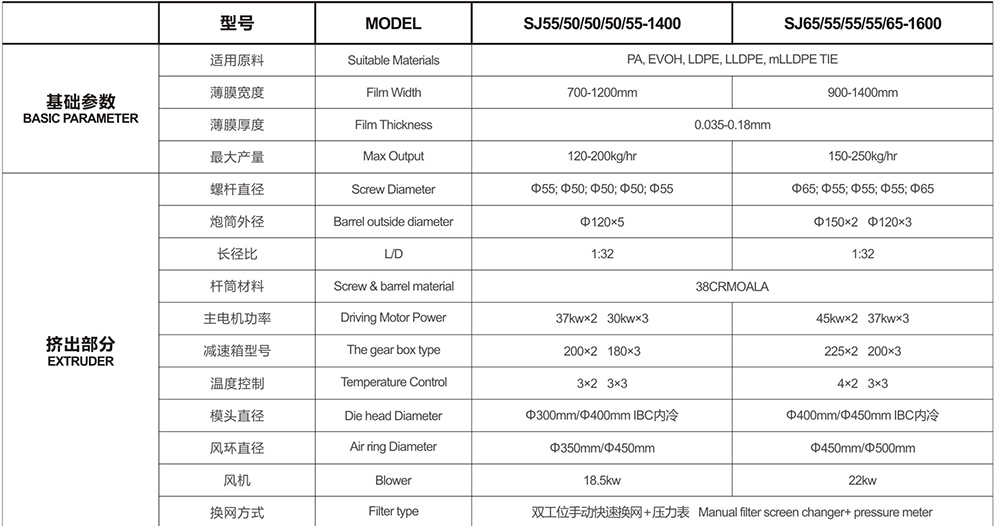

Film Width:700-1200mm

Material: PA, EVOH, LDPE, LLDPE, mLLDPE

Output: 120-200kg/hr

Characteristics:

1. for food package, and column air bag.

2. Gravimetric Dosing Unit

3. Conical 5 layers die mould

4. Central Gap Winder

5. Auto Thickness control system

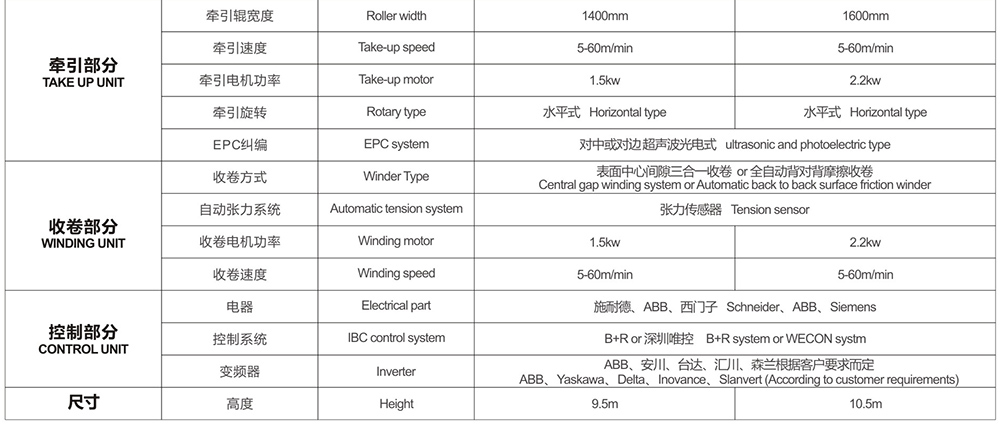

Spec: