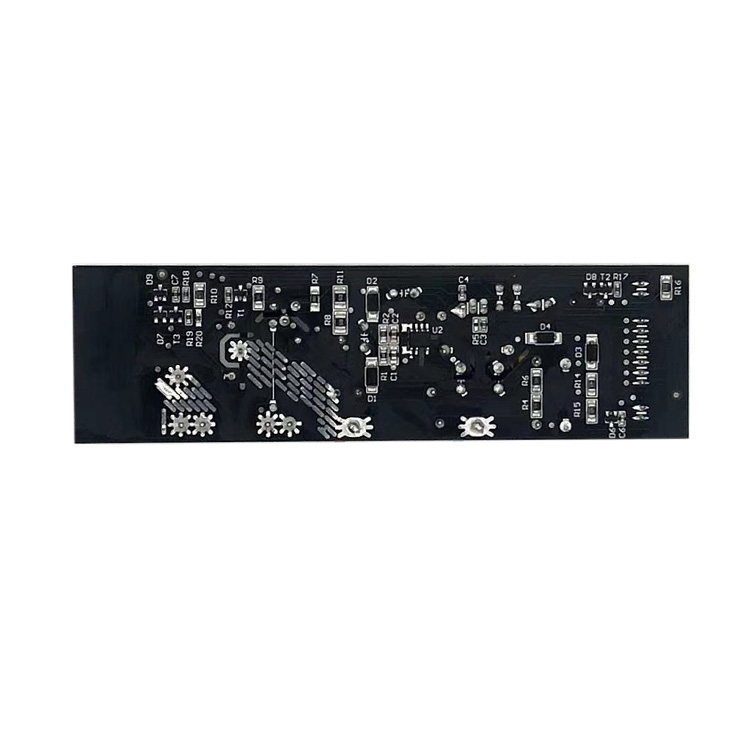

Air Fryer PCBA Manufacturer

Xianglong Electronics focuses on PCBA development solutions

for smart homes, deeply cultivates core technologies, and supports customized

development to meet the diversified needs of the small household appliance

consumer market. After years of in-depth research, we have launched air fryer

program design, dedicated to serving major domestic and foreign brands, foreign

trade merchants and cross-border e-commerce; at the same time, we can also

provide industry customers with the highest quality program design services. To

meet the needs of different customers, we can provide R&D, design and

production of PCBA.

Advantages of the air fryer solution launched by Xianglong:

1. Precise time control and temperature control

The precise control system defines food: high temperature and

tender roasting, good color and taste; crispy outside and tender inside, juicy

taste; fragrant but not dry, strong but not woody, smooth and moist, and long

aftertaste.

2. Multi-speed operation mode, which can meet the cooking

requirements of different foods

We can meet the different requirements of different

customers, and we can meet 600 recipes for you to choose.

3. Simulate customer requirements to achieve multi-purpose

use of one machine

It can realize frying, frying, baking, roasting, and can be

compatible with the functions of mini oven, fryer, frying pan, toaster,

sandwich maker, egg cooker, and defrosting box. A pot in hand, there are many.

4. Multi-level voltage design

It can realize the selection of different models under

multiple voltages, and can also customize the solution, which can be realized

from 85-264VAC.

5. Reliability

Our solution design has undergone strict reliability verification:

vibration, drop, gravity shock, high temperature and high humidity, cold and

heat cycle and high acceleration stress, double eighty-five, salt spray, EMI.

6. Process control

Our production has undergone strict quality control and

process control to ensure the quality assurance of each PCBA. Each process is

checked by quality personnel, and advanced production equipment is used to

ensure the consistency and reliability of processing. Automated testing

equipment ensures that all products are screened before shipment.