Product Item:Alumina ceramic bushing

Ceramic bushing types:

Multiple fluted and capped bushings

Re-entrant bushings

Tubular bushings

Barrel and cylindrical bushings

Cable terminations

Function of bushing

The flexibility of the use of bushing is relatively high, it can play a lot of role, generally speaking, bushing is a kind of parts to protect the equipment.The use of bushing can reduce wear, vibration and noise of equipment, and has the effect of anti-corrosion.The use of bushing can also facilitate the maintenance of mechanical equipment, simplify the structure of equipment and manufacturing process.

The function that bushing plays in actual work has a lot to do with its application environment and purpose.In valve applications, bushing is fitted to cover the stem to reduce valve leakage and seal.In the field of bearing application, the use of bushing can reduce the wear between bearing and shaft seat and avoid the increase of clearance between shaft and hole.

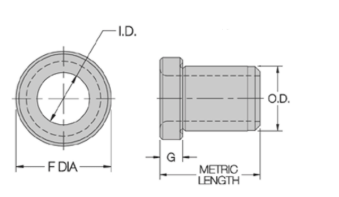

Size:

|

Alumina ceramic bushing

|

|

Item NO.

|

ID (mm)

|

OD (mm)

|

LENGTH (mm)

|

F DIA (mm)

|

G (mm)

|

ID (mm)

|

OD (mm)

|

LENGTH (mm)

|

F DIA (mm)

|

G (mm)

|

|

CS-B-01

|

1.75

|

4

|

6

|

7

|

2

|

8.4

|

15

|

12

|

18

|

3

|

|

CS-B-02

|

2.55

|

5

|

6

|

8

|

2

|

10.8

|

18

|

12

|

22

|

4

|

|

CS-B-03

|

4.5

|

8

|

12

|

11

|

2.5

|

14.5

|

22

|

28

|

26

|

4

|

Application:

Ceramic bushing is a ceramic connector for industry parts. Bushing can be welding, adhesive, inset with the metals use for the industry parts. Due to Ceramic bushing produced by technical ceramic with excellently properties.like a alumina ceramic bushing,zirconia bushing,siliconia bushing.

In the moving parts, because of long-term friction caused by the wear of parts, when the shaft and hole clearance wear to a certain extent must be replaced parts, so the designer in the design of the lower hardness, better wear resistance material for the shaft sleeve or bushing, so as to reduce the wear of the shaft and seat.

Points of Alumina Ceramic Bushing Sleeve:

1.High alumina purity:al2o3>95%,good corrosion resistance.

2.High temperature resistance,1600C in long use,1700C in short use.

3.Good thermal stock,no easy to crack.

4.High slip casting density.

Properties :

• High hardness with low density

• Wear & abrasion resistant

• Resists strong acid and alkali attack at high temperatures

• Excellent electrical insulation properties

• High compressive strength

• High mechanical Strength

• Excellent refractory material

• Moderate thermal conductive and thermal expansion rates

• Resistant to thermal shock

• High dielectric strength

• Transparent to microwave radio frequencies

Why choose CS CERAMIC

6 Steps Inspection Processes

15+ Years Oversea Market experience

30+ Years Manufacturer

300+ Members Professional Team

8000+ Kinds of alumina ceramic parts in Stock

Shipping:We do international shipping .

OEM : All sizes can be customized,Can be made into various of complex shapes, high dimension accuracy.

Please mark clearly height, bottom diameter, top diameter, wall thickness and any special requirements i.e. lips etc. To speed up quotations please supply a drawing and if appropriate, the name of the system in which they are to be used.

Technical reference

|

CS Ceramic's products accuracy

|

|

Shaft part:

|

0.0015mm for axial dimensions

|

|

0.001mm for circular degree

|

|

0.0025mm for concentricity

|

|

0.01 for roughness

|

|

The minimum processing aperture:

|

0.3mm, and depth limit 3mm

|

|

0.002mm for axial dimensions of diameter 1mm aperture

|

|

0.02~0.04 for roughness

|

|

Tolerance of plane processing:

|

0.002 for flatness

|

|

0.0015mm for measuring tolerance

|

|

Ceramic processing thread:

|

processing internal thread size limit M2

|

|

Thread accuracy gb-7h

|

|

Unlimited size for external thread

|

|

Thread accuracy gb-6g

|