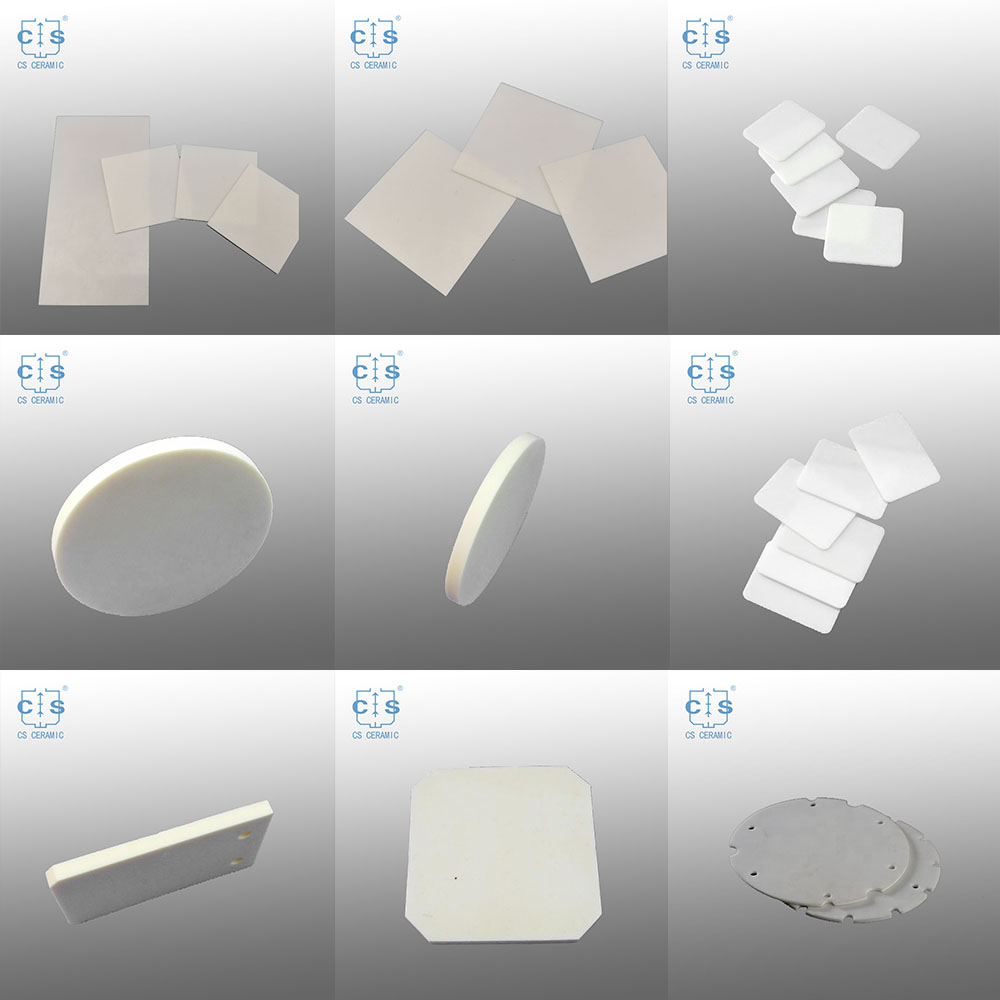

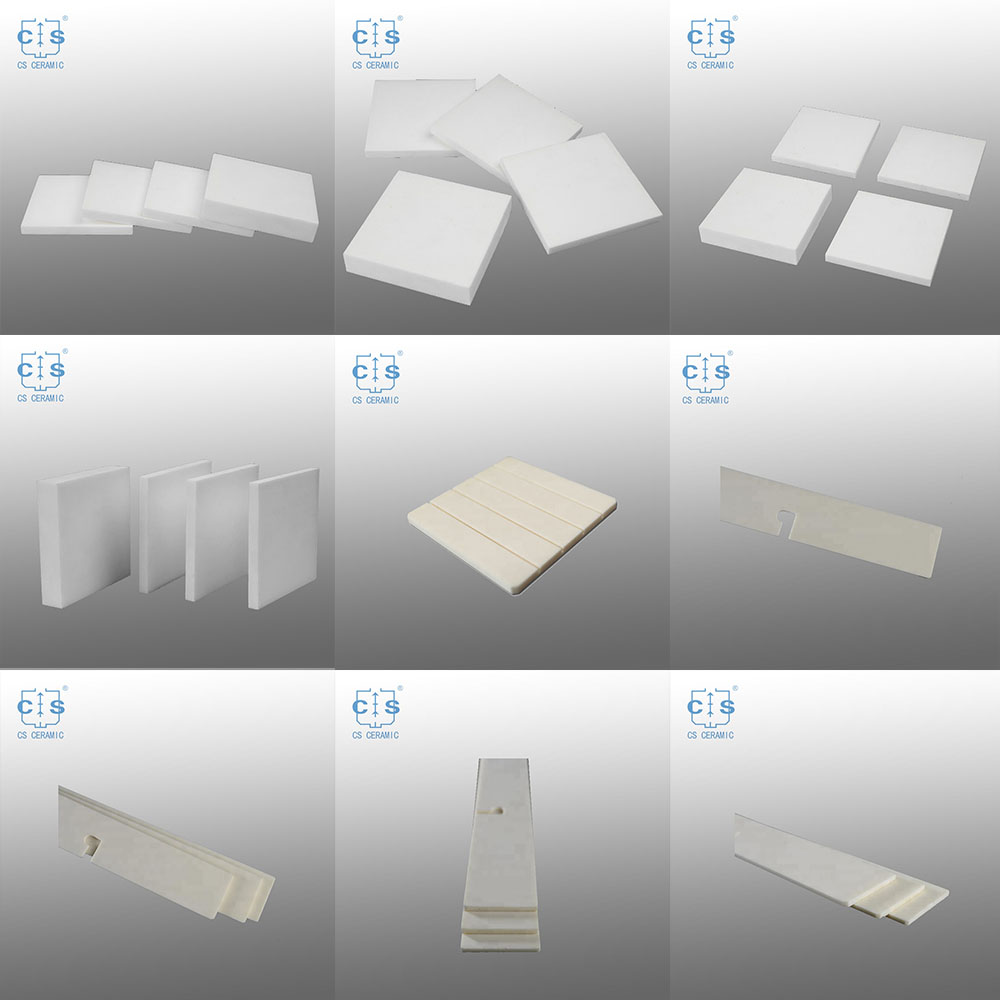

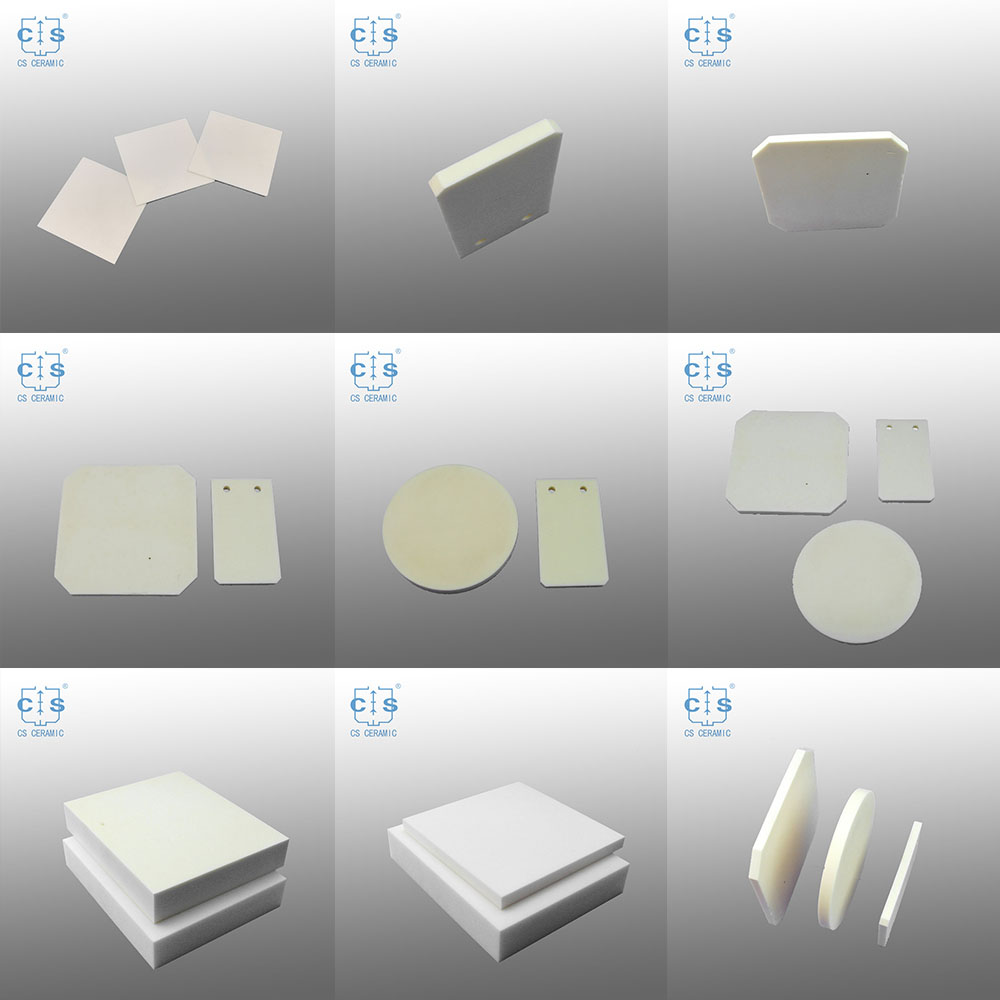

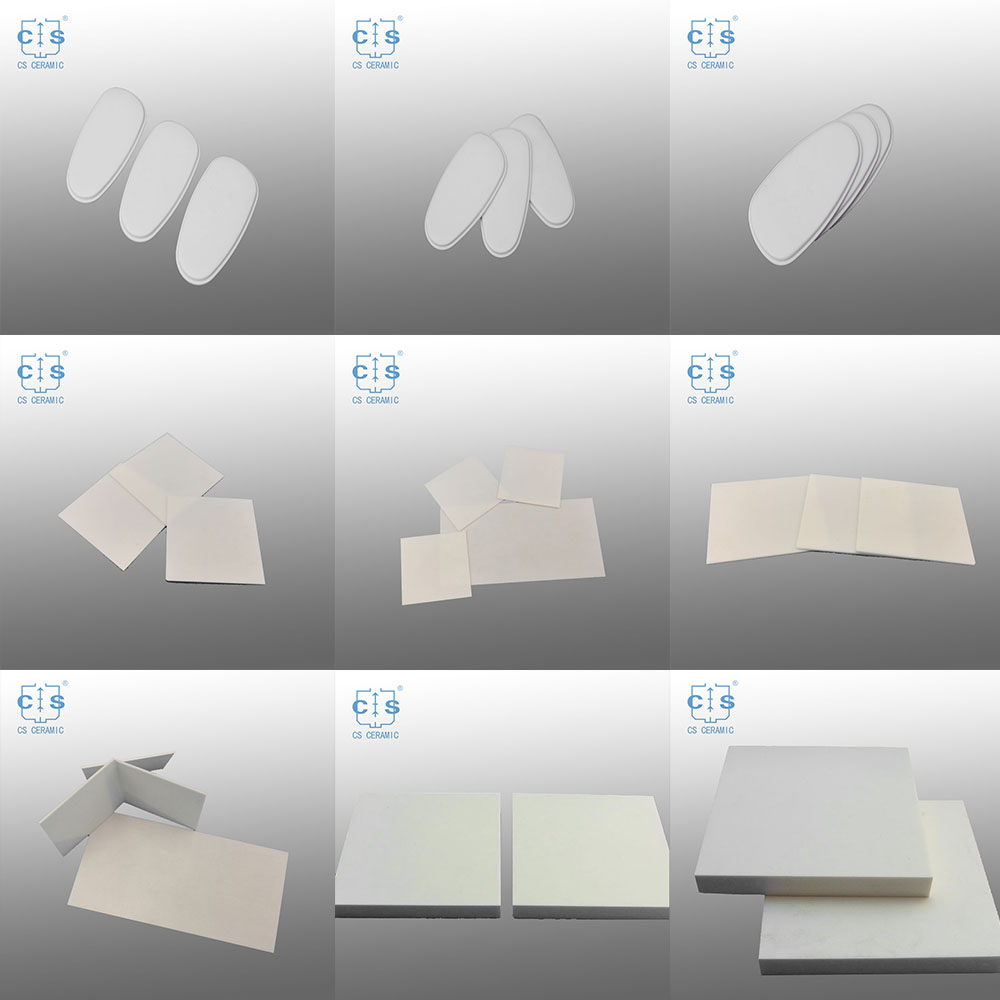

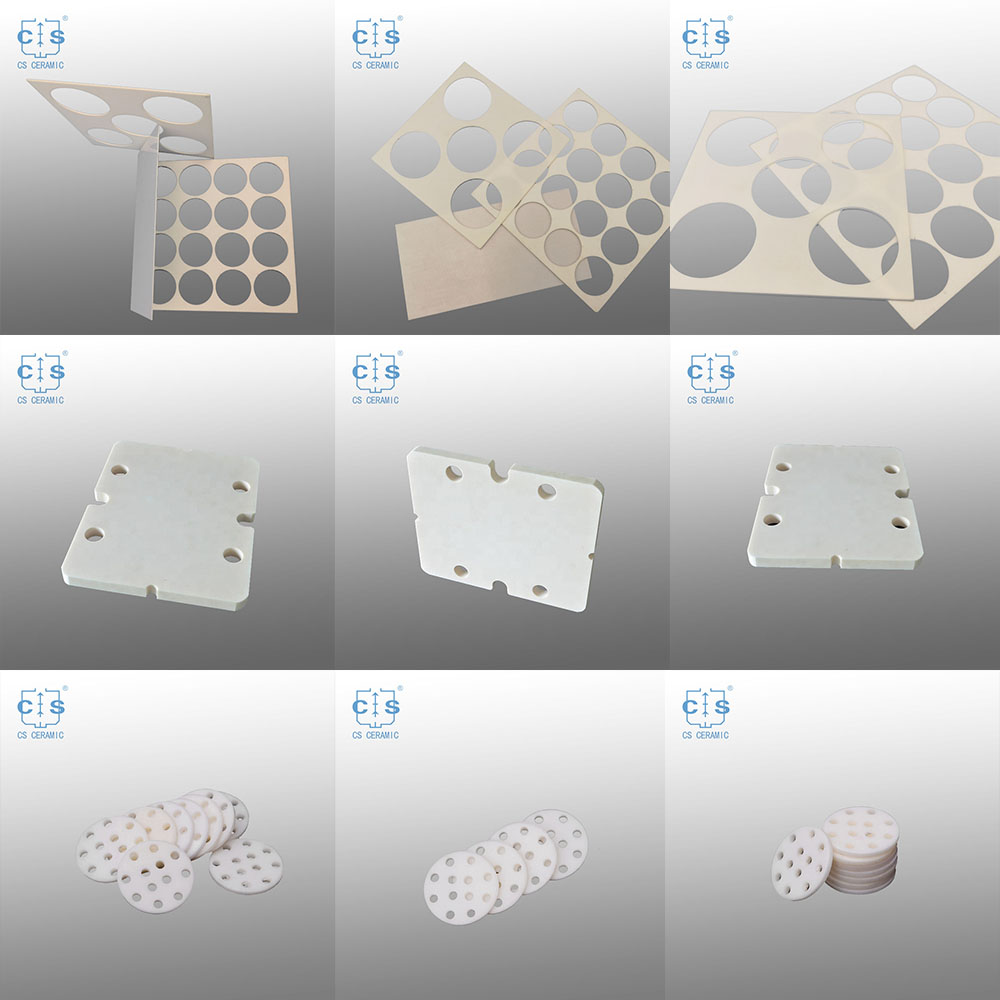

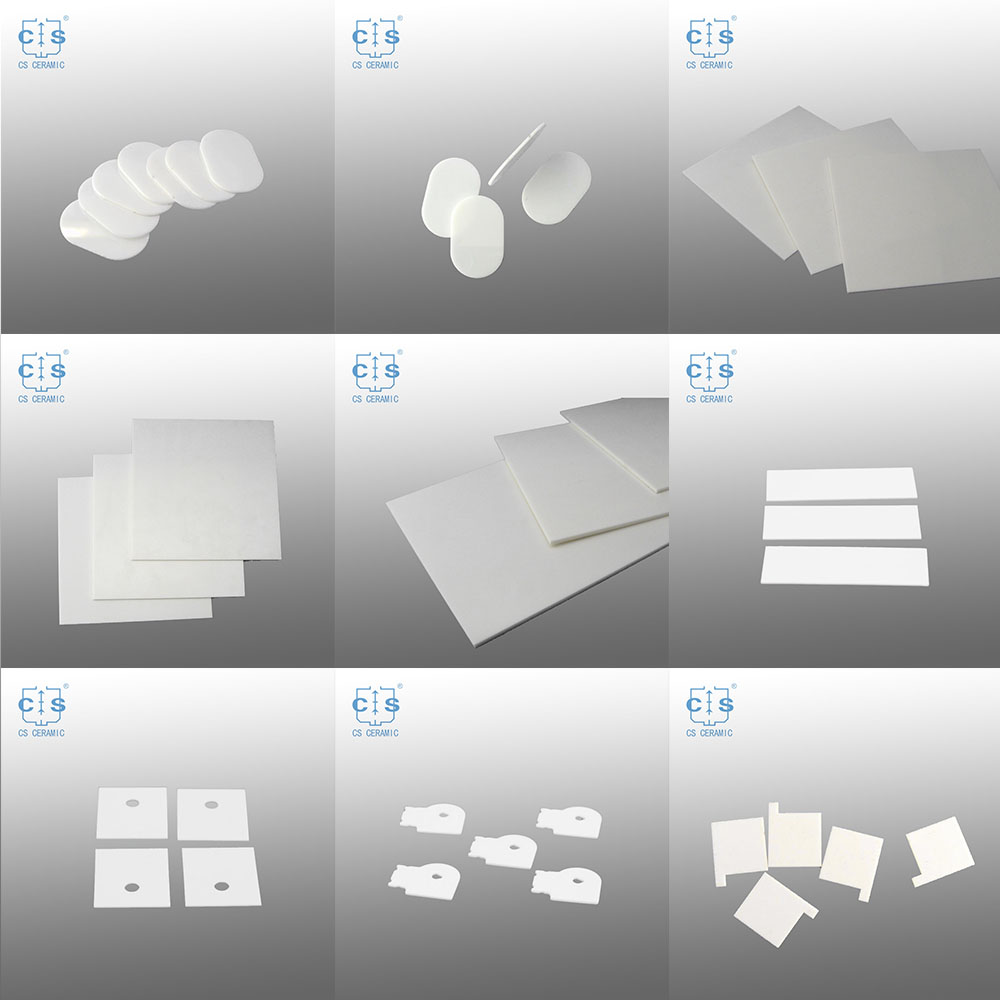

Product Item: Alumina Ceramic Substrates Sheet/Wear Plate/Disc

Product Description

|

1.Product thickness up to 0.3mm,Max length to 280mm. tolerance :± 0.01mm;

|

|

2.Conventional thickness:0.6mm.1mm.2mm.3mm.4mm

|

|

3. One side polished / two sides polished: for deep processing, the surface roughness can be controlled below Ra0.02um;

|

|

4.After molding according to the needs of laser processing holes, slots and so on.

|

|

5.Without crack and chips around of all edges.

|

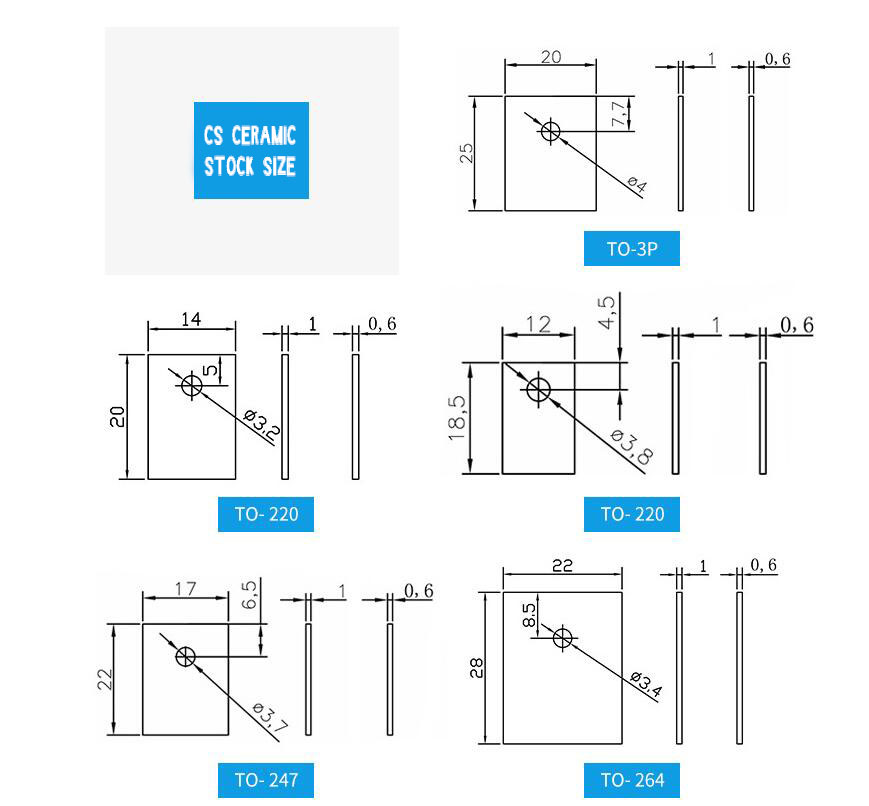

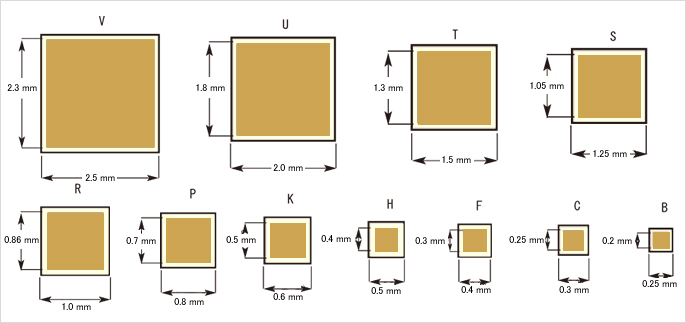

Size details :

|

Alumina Ceramic Substrate stock size

|

|

Item NO.

|

Length* Width*Thickness -H mm

|

Item NO.

|

Length* Width*Thickness -H mm

|

Item NO.

|

Length* Width*Thickness -H mm

|

Item NO.

|

Length* Width*Thickness -H mm

|

Item NO.

|

Length* Width*Thickness -H mm

|

|

CS-J-1

|

10*2,4*2

|

CS-J-36

|

17*22*1 H3.7

|

CS-J-71

|

20*25*2 H3.8

|

CS-J-106

|

24*104*1

|

CS-J-141

|

35*35*20mm

|

|

CS-J-2

|

10*2.4*1.5

|

CS-J-37

|

17*22*0.6 H3.7

|

CS-J-72

|

20*28*0.6

|

CS-J-107

|

25*34*0.6

|

CS-J-142

|

38.5*41*1

|

|

CS-J-3

|

10*15*0.6 H4

|

CS-J-38

|

17*22*0.6

|

CS-J-73

|

20*28*2

|

CS-J-108

|

25*40*1

|

CS-J-143

|

39*91*0.6

|

|

CS-J-4

|

10*16*1.5 H3.5

|

CS-J-39

|

17*22*1.5

|

CS-J-74

|

20*31.85*1 H3.85

|

CS-J-109

|

25*40*0.6

|

CS-J-144

|

40*30*1 H3.5

|

|

CS-J-5

|

10*20*1.6

|

CS-J-40

|

17*22*1

|

CS-J-75

|

20*32.1*1 H3.85

|

CS-J-110

|

25*110*0.6

|

CS-J-145

|

40*56*1

|

|

CS-J-6

|

10*16*6

|

CS-J-41

|

17*37.1*1

|

CS-J-76

|

20*35*1

|

CS-J-111

|

26*30*1 H3.2

|

CS-J-146

|

40*43*0.6

|

|

CS-J-7

|

10*10*2

|

CS-J-42

|

17*25*1

|

CS-J-77

|

21.5*34.5*1.5 H3.5

|

CS-J-112

|

26*31*1 H3.5

|

CS-J-147

|

40*105*0.635

|

|

CS-J-8

|

10*14*2

|

CS-J-43

|

17.8*26*1 H3

|

CS-J-78

|

21*28*0.6

|

CS-J-113

|

26*35*1

|

CS-J-148

|

40*140*0.6

|

|

CS-J-9

|

10.4*18*1 H3.8

|

CS-J-44

|

17.8*21.5*1.5 H3.5

|

CS-J-79

|

21*28*0.8

|

CS-J-114

|

27*60*0.6

|

CS-J-149

|

40*150*1

|

|

CS-J-10

|

10.6*17*1 H3.8

|

CS-J-45

|

18*19*1.5

|

CS-J-80

|

21*28*1

|

CS-J-115

|

27*90*0.6

|

CS-J-150

|

40*260*1mm

|

|

CS-J-11

|

11*11*1

|

CS-J-46

|

18*23*2 H3

|

CS-J-81

|

21.8*30*1 H3

|

CS-J-116

|

27*48*1 H5

|

CS-J-151

|

44*16*1

|

|

CS-J-12

|

11*17*1

|

CS-J-47

|

18*24*0.6

|

CS-J-82

|

21.8*30*0.6 H3

|

CS-J-117

|

27.5*4.2*2.5

|

CS-J-152

|

44*28*0.6 H6

|

|

CS-J-13

|

11*7*1.5

|

CS-J-48

|

18*25.3*1.3 H3.2

|

CS-J-83

|

21.8*30*1

|

CS-J-118

|

28*40*1

|

CS-J-153

|

50*50*1

|

|

CS-J-14

|

11*18*1-H4

|

CS-J-49

|

18*25.3*1 H3.5

|

CS-J-84

|

21.8*30*0.6

|

CS-J-119

|

28*42*0.6

|

CS-J-154

|

50*50*3mm

|

|

CS-J-15

|

12*18.5*0.6-H3.8

|

CS-J-50

|

18*29*1 H3.5

|

CS-J-85

|

22*30*2

|

CS-J-120

|

28*44*0.6 H6

|

CS-J-155

|

55*18*2

|

|

CS-J-16

|

12*18*0.6-H3.8

|

CS-J-51

|

18*29.5*1 H3

|

CS-J-86

|

22*28*1 H3.4

|

CS-J-121

|

28*64*1

|

CS-J-156

|

75*18*2

|

|

CS-J-17

|

12*18.5*1

|

CS-J-52

|

18*26*1 H3

|

CS-J-87

|

22*28*0.6 H3.4

|

CS-J-122

|

28*72*1

|

CS-J-157

|

100*100*1

|

|

CS-J-18

|

12*18.5*0.6

|

CS-J-53

|

18*26*0.6 H3

|

CS-J-88

|

22*28*1

|

CS-J-123

|

29*33*1.3

|

CS-J-158

|

100*100*2

|

|

CS-J-19

|

12.7*16.5*1.8 H-3.8

|

CS-J-54

|

18*26*0.6 H3.5

|

CS-J-89

|

22*28*0.6

|

CS-J-124

|

30*38*1 H3.5

|

CS-J-159

|

100*100*3

|

|

CS-J-20

|

13*19*0.6

|

CS-J-55

|

18.5*25*0.6 H3.8

|

CS-J-90

|

22*25*1 H3.6

|

CS-J-125

|

30*40*1 H3.5

|

CS-J-160

|

120*160*2mm

|

|

CS-J-21

|

14*18*3 H-3.4

|

CS-J-56

|

18.5*27*0.6 H3.8

|

CS-J-91

|

22*25*0.6 H3.1

|

CS-J-126

|

30*43*0.6 H4.5

|

CS-J-161

|

120*160*3mm

|

|

CS-J-22

|

14*19*2 H3.5

|

CS-J-57

|

19*23*2 H3.7

|

CS-J-92

|

22*25*1 H3.1

|

CS-J-127

|

32*50*1

|

CS-J-162

|

120*160*4mm

|

|

CS-J-23

|

14*20*1H3.2/3.5

|

CS-J-58

|

20*23*0.6

|

CS-J-93

|

22*22*0.6 H3

|

CS-J-128

|

32*60*1

|

CS-J-163

|

120*160*6mm

|

|

CS-J-24

|

14*20*0.6H-3.2

|

CS-J-59

|

20*26*1 H3.3

|

CS-J-94

|

22*35*1

|

CS-J-129

|

33*53*1.3

|

CS-J-164

|

160*160*1

|

|

CS-J-25

|

14*20*1

|

CS-J-60

|

20*2*1 H4

|

CS-J-95

|

22*35*1.5 H3.5

|

CS-J-130

|

33*73*1.3

|

CS-J-165

|

160*160*0.6

|

|

CS-J-26

|

14*20*0.6

|

CS-J-61

|

20*26*1

|

CS-J-96

|

23*34*1 H3.2

|

CS-J-131

|

33.6*51.4*0.8 H5

|

CS-J-166

|

D50*2mm-circle

|

|

CS-J-27

|

14*20*2

|

CS-J-62

|

20*26*0.6

|

CS-J-97

|

24*30*1

|

CS-J-132

|

33.6*51.4*2 H5

|

CS-J-167

|

D50*2.5mm-circle

|

|

CS-J-28

|

14*20*2 H3.2

|

CS-J-63

|

20*25*1 H4

|

CS-J-98

|

24*35.5*1

|

CS-J-133

|

34*64*0.6

|

CS-J-168

|

50*3mm-circle

|

|

CS-J-29

|

15*19.5*1 H3.8

|

CS-J-64

|

20*25*0.6 H4

|

CS-J-99

|

24*40*0.6

|

CS-J-134

|

34*39*0.6

|

|

|

|

CS-J-30

|

15*2*2.4

|

CS-J-65

|

20*25*1 H3.8

|

CS-J-100

|

24*60*1

|

CS-J-135

|

35*48*1 H5.5

|

|

|

|

CS-J-31

|

16*21*2.5 H3.5

|

CS-J-66

|

20*25*0.6 H3.8

|

CS-J-101

|

24*70*0.6

|

CS-J-136

|

35*68*1

|

|

|

|

CS-J-32

|

16*22*0.6 H3.3

|

CS-J-67

|

20*25*1 H3.2

|

CS-J-102

|

24*72*1

|

CS-J-137

|

35*45*1

|

|

|

|

CS-J-33

|

16*22*0.6 H4

|

CS-J-68

|

20*25*1

|

CS-J-103

|

24*90*0.6

|

CS-J-138

|

35*85*0.6

|

|

|

|

CS-J-34

|

16*22*0.6 H3.7

|

CS-J-69

|

20*25*0.6

|

CS-J-104

|

24*95*1

|

CS-J-139

|

38*38*0.6

|

|

|

|

CS-J-35

|

16*46*1

|

CS-J-70

|

20*25*2

|

CS-J-105

|

24*125*1

|

CS-J-140

|

38*50*0.6

|

|

|

Drawing of TO-220, TO-247,TO-264, TO-3P

More samll plate size :

9 advantages of CS CERAMIC ‘S Alumina Ceramic Substrate :

|

1. Fast heat dissipation

|

|

With small thermal capacity, heat storage of ceramic is poor, so heat rejection will not be influenced by “heat ladder” like metallic radiating fin.

|

|

2. High insulation, high temperature resistance, oxidation resistance, acid and alkali resistance

|

|

With the feature of high insulation, high temperature resistance, oxidation resistance, acid and alkali resistance, low thermal expansion coefficient, it can be ensured that ceramic radiating fin can work stably in high or low temperature occasion or other severe environment.

|

|

3. Multidirectional heat rejection

|

|

Heat dissipation speed of ceramic can be further enhanced due to its multidirectional heat rejection.

|

|

4. Natural inorganic material

|

|

Natural inorganic material, which belongs to EU exempted products, and it’s environmental compliance.

|

|

5. Anti-interference and antistatic

|

|

With effective anti-interference and antistatic, also moisture absorption, ceramic material does not influence working result of equipment.

|

|

6. With fast heat dissipation speed due to polycrystalline structure

|

|

Heat dissipation area can be increased for micro porous structure of ceramic, so heat dissipation effect is also enhanced significantly. With the same condition, heat dissipation of ceramic is much faster than copper or aluminum in natural environment. While in closed environment, heat rejection of ceramic is as 8.8 times as metallic materials, which indicates obvious advantage of heat dissipation speed.

|

|

7. Space saving

|

|

Volume of ceramic dissipating fin is small, and its weight is light, so space occupation is also small, both material and freight cost can be saved, and quite suitable for reasonable layout design of product.

|

|

8. IC, MOS, audion, etc.

|

|

Aluminum oxide ceramic plate is suitable for surface heat source that need heat dissipation, such as IC, MOS, audion, schottky, IGBT, etc., and large current and high voltage occasion, since electric leakage and breakdown can be prevented, and without noise, so coupling capacitor with power device like MOS will not formed, and filtering process can be simplified.

|

|

9. Suitable for high-power equipment,

|

|

It’s suitable for high-power equipment, and the required creep distance is shorter than metallic materials, so the board space can be saved further, which contributes to design work and approval of certificates, also suitable for light, thin, short and small design space.

|

|

Application: high-power audion, file-effect tube, voltage regulator module (LM78, LM317, series), audio power amplifier module (TDA series), high-power controllable silicon module (Omron series), packaged rectifier module and insulation of other electric heating element at high temperature, insulation and heat dissipation of high power LED light circuit board.

|

|

Typical application: high-density switching power supply, high-frequency communication equipment, induction cooker, electrical heat generating equipment and products.

|

Applications :

|

1. High-power power semiconductor module;Semiconductor refrigerator and electronic heater;Power control circuit, power hybrid circuit.

|

|

2. Intelligent power module;High frequency switching power supply, solid state relay.

|

|

3. Automotive electronics, aerospace and military electronic components.

|

|

4. Solar panel components;Telecommunication private exchange, receiving system;Laser and other industrial electronics.

|

|

5.Alumina Ceramic Substrate for LED Ceramic Suite, Printers,Direct Bonding Copper.

|

Why Choose Us ?

|

1000+ Kinds of Alumina Ceramic Substrate in Stock

|

|

15+ Years Oversea Market experience

|

|

Experienced R&D Department; OEM or ODM according to buyer’s requirement.

|

|

Strict quality control and timely delivery guaranteed.

|

|

Trial order or small order acceptable.Reasonable price.

|

|

Additional value such as creative innovation.

|

Shipping :We do international shipping .

More Alumina Ceramic Substrate picture: