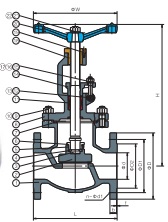

ANSI Class150 Class300 Stainless steel Flange globe valve

The opening and closing parts of the stainless steel flange globe valve are plug shaped disc, sealing surface is flat or conical surface, disc along the center line of the seat for linear motion.Stem movement, (common name: dark stem), also can be up and down rotary stem type, (common name: rising stem) globe valve refers to the closing member (disc) along the center line of the seat of the valve.

Depending on this movement of the disc, the variation of the seat orifice is proportional to the disc travel.Due to the relatively short stem opening or closing stroke of this type of valve, and the very reliable cutting function, and the seat port changes in a direct proportion to the stroke of the disc, it is very suitable for flow regulation.Therefore, this type of stop globe valve is ideal for cutting or regulating and throttling.

Stainless steel flange globe valve is suitable for all kinds of corrosive medium pipeline, has good corrosion resistance, enough strength.Alloy steel globe valves are suitable for high temperature resistant steam and oil pipeline, with high temperature resistance characteristics.Stainless steel flange globe valve is mainly used in petrochemical, chemical, electric power, metallurgy, medicine, food and other industries.

Features:

1/2"~12"(DN15~DN300)

Working pressure:CLASS150/300

Working temperature: 425℃

Rising stem

Design:ASME B16.34,BS1873,API623

Flange dimension: ASME B16.5

Face to face:ASME B16.10

Inspection & testing: API623/BS1873/ASME 16.34

Material List

|

|

No.

|

PARTS

|

MATERIAL

|

|

1

|

Body

|

WCB+13Cr

|

CF8

|

CF8M

|

|

2

|

Disc

|

WCB+13Cr

|

CF8

|

CF8M

|

|

3

|

Stem

|

20Cr13

|

304

|

316

|

|

4

|

Open Ring

|

45

|

304

|

316

|

|

5

|

Disc Nut

|

35

|

304

|

316

|

|

6

|

Thrust Washer

|

Q235A

|

304

|

316

|

|

7

|

Gasket

|

PTFE/304+GRAPHITE

|

|

8

|

Bonnet

|

WCB

|

CF8

|

CF8M

|

|

9

|

Bolt

|

35CrMo

|

304

|

304

|

|

10

|

Nut

|

45

|

304

|

304

|

|

11

|

Packing

|

PTFE/FLEXIBLE GRAPHITE

|

|

12

|

Clevis Pin With Head

|

35

|

304

|

304

|

|

13

|

Split Pin

|

Q235A

|

304

|

304

|

|

14

|

Gland

|

WCB

|

CF8

|

CF8M

|

|

15

|

Eye Bolts

|

35CrMo

|

304

|

304

|

|

16

|

Flat Pad

|

65Mn

|

304

|

304

|

|

17

|

Nut

|

45

|

304

|

304

|

|

18

|

Stem Nut

|

BRONZE

|

|

19

|

Screws

|

35CrMo

|

304

|

304

|

|

20

|

Handwheel

|

FCD/WCB

|

|

21

|

Flat Pad

|

65Mn

|

304

|

304

|

|

22

|

Nut

|

45

|

304

|

304

|

Unit:mm

Dimensions CLASS 150

|

Nominal Diameter

|

L

|

d

|

D2

|

D1

|

D

|

b

|

f

|

n-φd1

|

H

|

W

|

|

15

|

1/2"

|

108

|

15

|

35

|

60.3

|

90

|

8

|

2

|

4-16

|

178

|

120

|

|

20

|

3/4"

|

117

|

20

|

43

|

70

|

100

|

8.9

|

2

|

4-16

|

182

|

140

|

|

25

|

1"

|

127

|

25

|

51

|

79.4

|

110

|

9.6

|

2

|

4-16

|

201

|

140

|

|

32

|

1-1/4"

|

140

|

32

|

63.5

|

88.9

|

115

|

11.2

|

2

|

4-16

|

238

|

160

|

|

40

|

1-1/2"

|

165

|

40

|

73

|

98.4

|

125

|

12.7

|

2

|

4-16

|

249

|

160

|

|

50

|

2"

|

203

|

50

|

92

|

120.7

|

150

|

14.3

|

2

|

4-19

|

263

|

200

|

|

65

|

2-1/2"

|

216

|

65

|

105

|

139.7

|

180

|

15.9

|

2

|

4-19

|

312

|

200

|

|

80

|

3"

|

241

|

80

|

127

|

152.4

|

190

|

17.5

|

2

|

4-19

|

336

|

250

|

|

100

|

4"

|

292

|

100

|

157

|

190.5

|

230

|

22.3

|

2

|

8-19

|

388

|

300

|

|

125

|

5"

|

356

|

125

|

185

|

216

|

255

|

22.3

|

2

|

8-22

|

467

|

350

|

|

150

|

6"

|

406

|

150

|

216

|

241.3

|

280

|

23.9

|

2

|

8-22

|

529

|

400

|

|

200

|

8"

|

495

|

200

|

270

|

298.5

|

345

|

27

|

2

|

8-22

|

667

|

450

|

|

250

|

10"

|

622

|

250

|

324

|

362

|

405

|

28.6

|

2

|

12-25

|

825

|

500

|

|

300

|

12"

|

698

|

300

|

381

|

431.8

|

485

|

30.2

|

2

|

12-25

|

947

|

600

|

Unit:mm

|

Dimensions CLASS 300

|

Nominal Diameter

|

L

|

d

|

D2

|

D1

|

D

|

b

|

f

|

n-φd1

|

H

|

W

|

|

15

|

1/2"

|

152

|

15

|

35

|

66.7

|

95

|

12.7

|

2

|

4-16

|

182

|

140

|

|

20

|

3/4"

|

178

|

20

|

43

|

82.6

|

115

|

14.3

|

2

|

4-19

|

187

|

140

|

|

25

|

1"

|

203

|

25

|

51

|

88.9

|

125

|

15.9

|

2

|

4-19

|

208

|

160

|

|

32

|

1-1/4"

|

216

|

32

|

63.5

|

98.4

|

135

|

17.5

|

2

|

4-19

|

244

|

160

|

|

40

|

1-1/2"

|

229

|

40

|

73

|

114.3

|

155

|

19.1

|

2

|

4-22

|

255

|

200

|

|

50

|

2"

|

267

|

50

|

92

|

127

|

165

|

20.7

|

2

|

8-19

|

269

|

200

|

|

65

|

2-1/2"

|

292

|

65

|

105

|

149.2

|

190

|

23.9

|

2

|

8-22

|

320

|

250

|

|

80

|

3"

|

318

|

80

|

127

|

168.3

|

210

|

27

|

2

|

8-22

|

341

|

250

|

|

100

|

4”

|

356

|

100

|

157

|

200

|

255

|

30.2

|

2

|

8-22

|

393

|

300

|

|

125

|

5“

|

400

|

125

|

185

|

235

|

280

|

33.4

|

2

|

8-22

|

477

|

350

|

|

150

|

6”

|

444

|

150

|

216

|

270

|

320

|

35

|

2

|

12-22

|

541

|

400

|

|

200

|

8“

|

559

|

200

|

270

|

330.2

|

380

|

39.7

|

2

|

12-25

|

682

|

500

|

|

250

|

10”

|

622

|

250

|

324

|

387.4

|

445

|

46.1

|

2

|

16-29

|

839

|

600

|

|

300

|

12“

|

711

|

300

|

381

|

450.8

|

520

|

49.3

|

2

|

16-32

|

957

|

650

|

Packing & Delivery :

Packing Details : all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details : Generally it is 5-10 days if the goods are in stock. or 15-30 days if the goods are OEM or not enough

subject to the order quantity. But anyway,normally, we are able to make sure the delivery will not exceed 45 days.