Blind

Via PCB Built on Tg150℃ FR-4 With Immersion Gold 4-Layer FR-4 Circuit Board

(Printed

circuits boards are custom-made products, the picture and parameters shown are

just for reference)

1.1

General description:

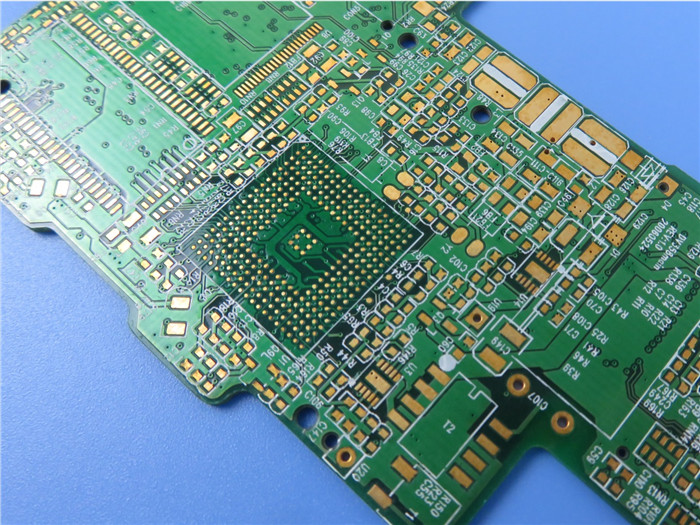

It's 1.6 mm thick with

white silkscreen(Taiyo) on green solder mask (Taiyo) and immersion gold on

pads. The base material is from ITEQ supplying single up PCB. They're

fabricated per IPC 6012 Class 2 using supplied Gerber data. Each 25 boards are

packed for shipment.

1.2

Features and Benefits :

1.2.1

Middle Tg FR-4 Shows low Z-CTE and excellent through hole reliability;

1.2.2 Immersion

gold has high solderability, no stressing and less contamination;

1.2.3

Multilayer shortened connection between electronic components;

1.2.4

16000㎡workshop and 8000 types of

PCB's per month;

1.2.5

Delivery on time: >98%

1.2.6

No minimum order quantity. 1 piece is available;

1.3

Applications:

Industrial

Computer

GPS

Tracking System

POS

Cash Register

Embedded

Systems

Data

Acquisition System

Microcontrollers

PC

and Notebook

1.4

Parameter and data sheet:

|

PCB SIZE

|

119 x 80mm=1PCS

|

|

BOARD TYPE

|

Multilayer

PCB

|

|

Number

of Layers

|

4 layers

|

|

Surface

Mount Components

|

YES

|

|

Through

Hole Components

|

YES

|

|

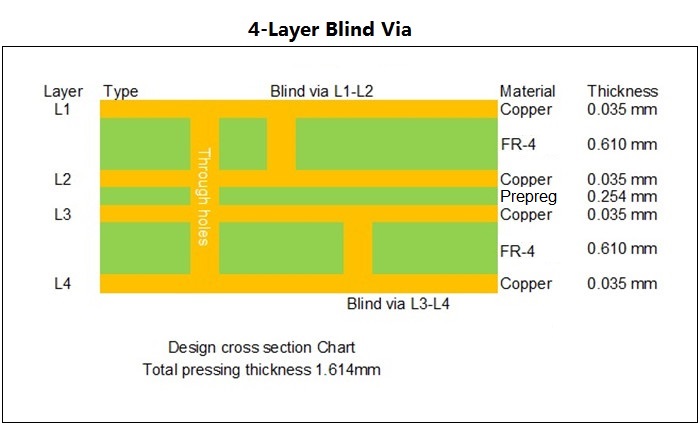

LAYER STACKUP

|

copper

------- 18um(0.5oz)+plate TOP layer

|

|

Core FR-4 0.61mm

|

|

copper ------- 35um(1oz) MidLayer 1

|

|

Prepreg 0.254mm

|

|

copper ------- 35um(1oz) MidLayer 2

|

|

Core FR-4 0.61mm

|

|

copper -------

18um(0.5oz)+plate BOT layer

|

|

TECHNOLOGY

|

|

|

Minimum Trace and Space:

|

4

mil / 4 mil

|

|

Minimum

/ Maximum Holes:

|

0.3

mm /3.5 mm

|

|

Number

of Different Holes:

|

9

|

|

Number

of Drill Holes:

|

415

|

|

Number

of Milled Slots:

|

0

|

|

Number

of Internal Cutouts:

|

0

|

|

Impedance

Control:

|

no

|

|

Number

of Gold finger:

|

0

|

|

BOARD

MATERIAL

|

|

|

Glass

Epoxy:

|

FR-4 Tg150℃,

er<5.4.IT-158, ITEQ

|

|

Final

foil external:

|

1oz

|

|

Final

foil internal:

|

1oz

|

|

Final

height of PCB:

|

1.6mm

±0.16

|

|

PLATING AND COATING

|

|

|

Surface Finish

|

Immersion Gold

|

|

Solder

Mask Apply To:

|

TOP and Bottom,

12micron Minimum

|

|

Solder

Mask Color:

|

Green,

PSR-2000 GT600D, Taiyo Supplied.

|

|

Solder

Mask Type:

|

LPSM

|

|

CONTOUR/CUTTING

|

Routing,

stamp holes.

|

|

MARKING

|

|

|

Side of

Component Legend

|

TOP

and Bottom.

|

|

Colour

of Component Legend

|

White, S-380W,

Taiyo Supplied.

|

|

Manufacturer

Name or Logo:

|

Marked on the

board in a conductor and leged FREE AREA

|

|

VIA

|

Plated

through hole(PTH), minimum size 0.3mm. Blind Via Top to Inner layer 1, Bottom

to Inner layer 2

|

|

FLAMIBILITY RATING

|

UL

94-V0 Approval MIN.

|

|

DIMENSION TOLERANCE

|

|

|

Outline

dimension:

|

0.0059"

|

|

Board

plating:

|

0.0029"

|

|

Drill

tolerance:

|

0.002"

|

|

TEST

|

100%

Electrical Test prior shipment

|

|

TYPE OF ARTWORK TO BE SUPPLIED

|

email

file, Gerber RS-274-X, PCBDOC etc

|

|

SERVICE AREA

|

Worldwide,

Globally.

|

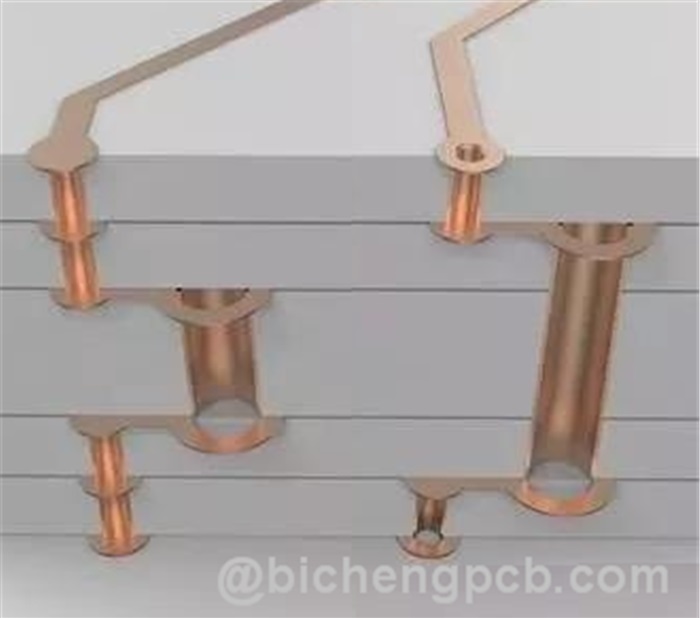

1.5 Composition of Holes:

The blind hole is located on the top and bottom

surface of the printed circuit board and has a certain depth for the connection

between the surface line and the inner line below. The depth of the hole

usually does not exceed a certain ratio (aperture). Buried hole is a connecting

hole located in the inner layer of the printed circuit board, which does not

extend to the surface of the circuit board.

The above two kinds of holes are located in the

inner layer of the circuit board. The formation of through hole process is used

before lamination, and several inner layers may be overlapped done during the

formation of the through hole.

The third is called a through hole, which

passes through the entire circuit board. It can be used to interconnect

internally or as an installation location hole for components. Because the

through hole is easier to realize and the cost is low, it is used in most

printed circuit boards instead of the other two. The following mentioned holes,

without special instructions, are considered as through holes.

From the design point of view, a hole is mainly

composed of two parts, one is the middle hole (drill hole), the other is the

pad area around the hole, see below. The size of these two parts determines the

size of the hole. Clearly, in

high-speed, high-density PCB design, designers

always want the holes the smaller the better, so that it can leave more wiring

space on the board.

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS: