The Class 300 flanged ball valve has cast steel WCB body, stainless steel ball, stem, seat ring along with Devlon seat insert.

Design Feature

1.Firesafe design as per API 607

2.With sealant injection for self lubricating

3.With antistatic design

4.With anti-blowout stem

5.With vent and drain port

6.Full bore design

7.Three-piece type and trunnion ball

8.Gear operated for easy operation

Quick Detail

|

Type

|

Ball Valve

|

|

Size

|

24"

|

|

Pressure

|

ANSI 300

|

|

Construction

|

Trunnion Type

Ball, 3-Piece Body, Side Entry, Full Bore

|

|

Connection

|

Flange

Connection

|

|

Operation

|

Gearbox

Operation

|

|

Body

Material

|

ASTM A216

WCB

|

|

Design Code

|

API 6D

|

|

Pressure

& Temp Code

|

ASME B16.34

|

|

Face to Face

|

ASME B16.10

|

|

End

Connection

|

ASME B16.5

|

|

Test &

Inspection Code

|

API 598,

API 6D

|

|

Fire Safe

|

API 607

|

|

Temperature

Range

|

-29℃~+200℃

|

|

Medium

|

WOG

|

|

Origin

|

China

|

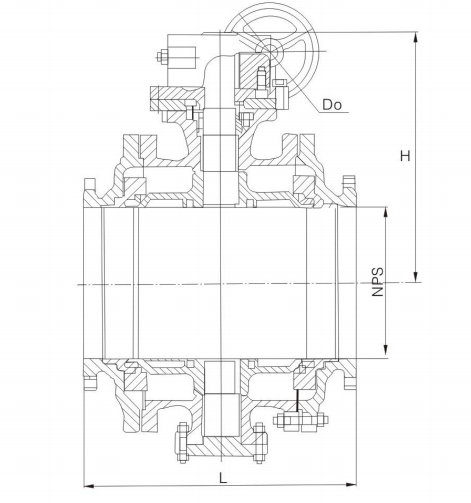

Dimension

|

CLASS 300

|

|

DN

|

mm

|

50

|

65

|

80

|

100

|

150

|

200

|

250

|

300

|

350

|

400

|

450

|

500

|

600

|

700

|

|

NPS

|

in

|

2

|

2.5

|

3

|

4

|

6

|

8

|

10

|

12

|

14

|

16

|

18

|

20

|

24

|

28

|

|

L

(RF)

|

mm

|

216

|

241

|

283

|

305

|

403

|

502

|

568

|

648

|

762

|

838

|

914

|

991

|

1143

|

1346

|

|

in

|

8.5

|

9.5

|

11.13

|

12

|

15.88

|

19.75

|

22.38

|

25.5

|

30

|

33

|

36

|

39

|

45

|

53

|

|

L1

(BW)

|

mm

|

216

|

241

|

283

|

305

|

457

|

521

|

559

|

635

|

762

|

838

|

914

|

991

|

1143

|

1346

|

|

in

|

8.5

|

9.5

|

11.13

|

12

|

18

|

20.5

|

22

|

25

|

30

|

33

|

36

|

39

|

45

|

53

|

|

L2

(RTJ)

|

mm

|

232

|

257

|

298

|

321

|

419

|

518

|

584

|

664

|

778

|

854

|

930

|

1010

|

1165

|

1372

|

|

in

|

9.13

|

10.13

|

11.75

|

12.63

|

16.5

|

20.38

|

23

|

26.13

|

30.63

|

33.63

|

36.63

|

39.75

|

45.89

|

54

|

|

H

|

mm

|

153

|

165

|

195

|

213

|

272

|

342

|

495

|

580

|

625

|

720

|

790

|

840

|

1050

|

1150

|

|

in

|

6.02

|

6.5

|

7.68

|

8.39

|

10.7

|

13.5

|

19.5

|

22.85

|

24.6

|

28.35

|

31

|

33.1

|

41.34

|

45.3

|

|

Do(W)

|

mm

|

400

|

400

|

600

|

850

|

1100

|

1500

|

*350

|

*350

|

*600

|

*600

|

*800

|

*800

|

*800

|

*800

|

|

in

|

15.74

|

15.74

|

23.62

|

33.46

|

43.3

|

59

|

13.8

|

13.8

|

23.6

|

23.6

|

31.5

|

31.5

|

31.5

|

31.5

|

|

RF(Kg)

|

|

18

|

27

|

47

|

80

|

118

|

200

|

365

|

530

|

740

|

1030

|

1320

|

1540

|

2600

|

3900

|

|

BW(Kg)

|

|

14

|

2

|

38

|

65

|

105

|

185

|

342

|

503

|

713

|

1000

|

1285

|

1498

|

2540

|

3825

|

|

*Worm Gear or Electric Actuator Operated

|

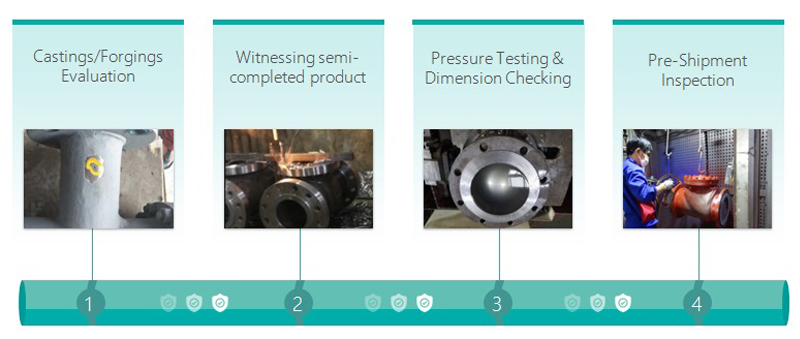

Dervos Quality Checking System

In Dervos, we control quality throughout the whole manufacturing process.

Casting inspection:

Though casting inspection, we can find out the problem of raw material, such as shoddy casting, unqualified wall thickness, chemical composition and so on, which ensure that you will not be cheated.

Machining Inspection:

On the one hand, we could ensure machining accuracy through this process. On the other hand, we can find out machining mistake as early as possible, to win more time for repairing and remaking

Final Inspection:

Final inspection activities include document and QC record review, visual examination, dimension check, pressure test, painting and packing check. You don’t need to come and inspect in person and all the documents could be provided as proof.