Bonve industrial rotary lobe

pumps are widely used in the fields of daily chemicals and fine chemicals.

As a pioneer with 17 years of experience, we always keep updating our pumps and

applied for a variety of patents, make sure higher compatibility for pump

sealing, more stability when working under high pressure and so on. As an

excellent manufacturer, our hard technical barriers have become a powerful help

for our Bonve pump reform and innovation. So far, our pumps have developed to

the fourth generation, which is long lasting, leak free, and proven in many

harsh applications.

In the transportation of resin,

we have a wealth of experience, considering that the resin is semi-solid at

room temperature during transportation, so we will use a pump with a thermal

insulation jacket, and we have six bearings in our pump, so that our pump has

higher stability. The

picture below is the application of our pumps in the resin industry.

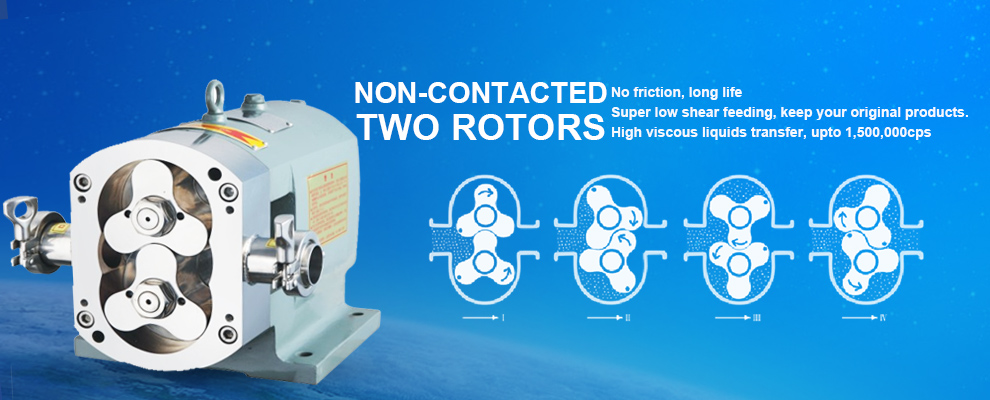

How pump works?

The even rotation of the rotor pair creates a vacuum on the

priming side of the pump, which can be defined by the direction of rotation of

the drive. This vacuum draws the liquid into the pump chamber. With further

rotation, the pumped medium is conveyed past the pump wall into the pressure

area. Up to six chamber charges are displaced with each drive rotation– depending on the rotor type. When the rotor is at a

standstill, the pump seals off almost completely.

parameter

|

Model

|

Displace

-ment

(L/r)

|

Rotation

speed

(r/min)

|

Flow

rate

(M³/h)

|

Dis.

Pre.

(Mpa)

|

Electrical

power

(Kw)

|

Suc.

Pre.

(Mpa)

|

Dia.

of inlet

and

outlet (mm)

|

|

25BV6 /12-2

|

0.15

|

20-600

|

2

|

0.1-1.2

|

1.1-2.2

|

-0.095

|

25

|

|

40BV6 /12-5

|

0.32

|

20-550

|

5

|

0.1-1.2

|

1.5-4

|

-0.095

|

40

|

|

50BV6 /12-10

|

0.65

|

20-550

|

10

|

0.1-1.2

|

2.2-7.5

|

-0.095

|

50

|

|

65BV6 /12-20

|

1.74

|

20-550

|

20

|

0.1-1.2

|

4-15

|

-0.095

|

65

|

|

80BV6 /12-30

|

2.48

|

20-550

|

30

|

0.1-1.2

|

5.5-22

|

-0.095

|

80

|

|

80BV6 /12-40

|

3.65

|

20-550

|

40

|

0.1-1.2

|

7.5-30

|

-0.095

|

100

|

|

125BV6 /12-50

|

4.60

|

20-550

|

50

|

0.1-1.2

|

11-45

|

-0.095

|

125

|

|

125BV6 /12-70

|

6.10

|

20-550

|

70

|

0.1-1.2

|

15-55

|

-0.095

|

125

|

|

125BV6 /12-80

|

7.63

|

20-550

|

80

|

0.1-1.2

|

18.5-75

|

-0.095

|

125

|

|

150BV6 /12-120

|

11.56

|

20-420

|

120

|

0.1-1.2

|

22-90

|

-0.095

|

150

|

|

150BV6 /12-150

|

14.22

|

20-420

|

150

|

0.1-1.2

|

37-110

|

-0.095

|

150

|

|

200BV6 /12-200

|

18.10

|

20-420

|

200

|

0.1-1.2

|

45-132

|

-0.095

|

200

|

|

250BV6 /12-250

|

22.92

|

20-420

|

250

|

0.1-1.2

|

55-160

|

-0.095

|

250

|

|

300BV6 /12-300

|

32.00

|

20-420

|

300

|

0.1-1.2

|

75-200

|

-0.095

|

300

|

What its

advantages?

-

Displacement: positive displacement, Displacement is proportional to the speed. Discharge pressure: upto 1.2Mpa.

-

Suction capacity: Movable pumps can be used to pump canned medium, with intake vacuum of 0.08 Mpa.

-

Work efficiency: upto 90%

-

Special mediums to handle: high viscosity upto 1.5million cps, high solid mediums upto 60%, sensitive mediums.

-

Reversible running allowed: Forward suction, reversal flushing can be realized with pump's symmetric structure, reversible transportation direction.

-

Dry running: with Bonve's special design on mechanical seal, dry running can be realized.

-

Maintenance: Compact structure, little space occupation, no need to move pipe systems when maintain.

-

Wear-resisting: all the contact parts are made of stainless steel. Nearly no wearing parts.

-

Low shearing: Low working speed, gap is kept between the rotors and between the rotor and the pump body, no friction, long life.

-

Replacement: take replace of screw pumps, gear pumps, centrifugal pump, diaphragm pump etc.

-

Low cost: high working efficiency, low consumption, environmental friendly, low maintenance, long life.

How to choose our

pump?

|

Selection Guideline

|

|

Liquid name:___________

|

|

Viscosity:_______cp Density:_______ Temperature:_____℃ PH value:________

|

|

Solid

content:_______ Max. size of

particle:_______

|

|

Capacity: Max. required__________ L/H Working required__________ L/H

|

|

Discharge

pressure: Max. required__________Mpa Working required__________ Mpa

|

|

Connection

type required: Thread[ ] Clamp[ ]

|

|

Installation

type: Fixed [ ] Movable[ ]

|

|

Voltage: ____ V Frequency: _____Hz

|

|

Liquid

contact material: SS304[ ] 316[ ] 316L[ ]

|

|

Special

request_____________________________________

|

|

Order

qty.

|

We

are so pleased with interest into Our Bonve Rotary Lobe Pumps. Hope we

can work with you and solve your pumping problem during production. Contact Mr.

Hank Li with his mail bvsales1@bonvepumps.comfor a pump solution.

Email: bvsales1@bonvepumps.com

Tel : 0086-574-87769810

Mobile: 0086-15669501367