|

Structure

|

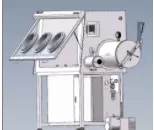

Integrated structure (Purification System integrated under the box)

|

|

Power Supply

|

110 - 220V AC, 50/60Hz, Single-phase

|

|

Glove box Box

|

Box Material 304 Stainless Steel (Type 304), thickness 3mm

Box Size(excluded antechamber and support)1220mm(L) x 750mm(W) x 900mm(H)

47.2 " x 29.5" x 35.4"

Box Support height: 900mm(35.43" )

|

|

Tray

|

Standard Layout

|

Two layers in box.

|

|

Option/Add: tool boxes or other

|

Various tool boxes, can be placed according to user needs.

|

|

Front window

|

Tilt design operating window, removable safety toughened glass front window, 8mm thickness,Wear resistance, corrosion resistance, good light transmission, sealing ring using 3/8 inch thick OMEGA sealing ring.

|

|

Option Window Open

|

The front window can be designed to open instead of fix, in order to put in a variety of instruments (custom function).

|

|

Environment of Box inside

|

H2O <1 ppm (20°C/68 ℉, 1 atm)

O2 <1 ppm (20°C/68 ℉, 1 atm)

|

|

Antechamber

|

Control way: manual

Design: two circular antechambers

Main chamber size: Φ360mm (Dia.)x 600mm(length)(location: right-side of box)

14.17 "(Dia.) x 23.62" (L)

Mini chamber size: Φ150 mm(Dia.) x 300mm(L)(location: right-side of box)

5.9 "(Dia.) x11.8" (L)

Vacuum degree:<=-0.1MPa(right side antechambers included main chamber and mini chamber, all of that are need vacuum and display. The vacuum pressure gauge brand is German WIKA.

|

|

Option/add auto control way

|

It will automatically control the antechamber by time setting and the number of times for gas exhaust and filling.

|

|

Option/Add: heating mode

|

Max temperature:200℃/ 392℉

Control accuracy:±2℃/±3.6℉

The main chamber and mini chamber are both can adding the heating function (compared with standard antechamber the size is a little different)

|

|

Working gas and regeneration gas

|

Working gas: 99.999% high pure N2, Ar, He and other inert gas

Control gas:99.999% high pure inert gas

Regeneration gas: mixing gas of working gas and H2,hydrogen(H2)Volume accounted for 5-10%

If the pure system only has moisture removal function, the regeneration gas is the same with working gas

|

|

Gas purification system

|

Single pure column:

German BASF Oxygen removal material, US UOP high moisture absorb material. The regeneration process of purification system is auto control and automatic moisture and oxygen removal function.

Gas purity can be sustained and keep long-term:H2O<1ppm, O2<1ppm.

|

|

Option dual columns purification system

(one in use and the other is reserve)

|

Why choose duel pure column? 1,The Pure column need to be regenerated after saturated by absorbing the oxygen and moisture. The regeneration time is 16hours. If there is no reserved column, it may stop working. (we recommend dual column purification system to factory or other unit which need glove box working Continuously); 2,The pure capacity of dual pure columns is two times as much as single column

|

|

Pressure control system

|

Box pressure can be auto controlled by PLC touch screen

Control accuracy:±1Pa

Can also be manually controlled by foot switch

|

|

Filter system

|

The ends of inlet and outlet both are provided with filter

The filter precision is: 0.3 mu m

|

|

Closed circulating fan

|

High speed frequency conversion fan, flow 0-100m3/h, microprocessor control, Stainless steel device for pressure testing.

With water cooling device (can equipped with water cooler and external refrigeration equipment)

|

|

Control system

|

SIEMENS colors touch screen (6 inches), PLC control system, Bilingual in Chinese and English can be switched

Pressure sensor: -2500~2500Pa touch screen, accuracy±1Pa

Pressure control: control the box pressure to one setting point (scope can be set)

|

|

measurements

|

Moisture analyzer: US GE brand, 0~1000ppm touch screen display, precision 0.1ppm

|

|

Oxygen analyzer: US GE brand, 0~1000ppm touch screen display, precision 0.1ppm

|

|

Vacuum Pump

|

Britain Brand EDWARDS, pumping speed 8.4-12m3/h, Model RV12

Extreme pressure 2 x 10-3 mbar/1.5 x 10-3 Torr

Inlet flange NW25

Outlet flange NW25

Noise level: 50 Hz 48 dBA

|

|

Glove

|

Brand: US NORTH

Material: Butyl

Model for standard 8B1532

|

|

illumination system

|

Equipped with Fluorescent lamp. Brand: PHILIPS

|

|

Solvent removal system

|

Efficient adsorption of activated carbon, can effectively remove trace organic solvents;

|

|

Spare KF40 standard joint

|

Special design to KF40 Joint, you can lead the water into the box

|

|

Can be connected to other devices (low temperature refrigerator, film coating machine, microscope, solvent purification system, low temperature cold trap, heating furnace, etc.)

|

low temperature refrigerator

|

|

|

microscope

|

|

|

Solvent Purification System

|

|

|

Coating machine

|

Inside connection(one door of Coating machine is inside of glove box)

Outside connection

|

|

Equipment size and room requirements

|

Overall size

|

1850mm(L) x 1000mm(W) x 1950mm(H)

72.83" x39.37" x 76.77"

|

|

Room size

|

2200mm(L) x 1500mm(W) x 2000mm(H)

86.6" x59" x 78.74"

|

|

Wooden Package size and weight

|

2185mm(L) x 1145mm(W) x 2300mm(H)

86" x 45" x 91" (5.8M3)

|

|

650 kg (1400 lbs)

|

|

Notice

|

When the gas is circulating, must ensure that the piping of the circulation system is clear and cannot be blocked (if the color of the filter is changed from white to black, the filter should be replaced timely).

No corrosive gas in the glove box.

It needs to regenerate the column when the moisture and oxygen indicators cannot meet the work requirements. If the corrosive gas is released from inside of glove box.(such as LiPF6 electrolyte),please do not use. you must put the bottle filled with liquid seal.

Vacuum pump needs to be checked the oil level and maintain in regular time.

|