Customized steel roof/door/gutter/purlin/greenhouse profiles roll forming machines are acceptable.

Product Name: Customized Sheet Metal Roll Forming Machines Stand Pillar Frame type

This YX29-200-1000 roll forming machine for roof sheet has film laminated function, see the marked out roller above, this part is for installing film laminated device for steel roof sheet.

We are the factory who is good at Customized manufacture Sheet Metal Roll Forming Machines, below trapezoidal metal sheet roof roll forming machine adopts stand pillar machine frame type, compare to traditional machine frame, it is good for user to maintenance whole roll forming machines, we can add lubricated oil any time, no need remove the gear cover again. Whole trapezoidal roof sheet roll forming machine with stand pillar machine frame looks more beautiful.

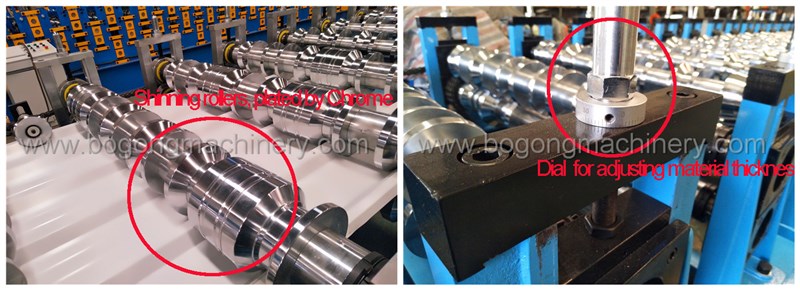

All the roll forming rollers are machined by CNC lathe, then fine polished, so full set metal sheet roof roll forming machine rollers are shinning and looks at mirror.On each station,we have installed dials for reading, when we change to produce another different thickness of raw material, we can adjust these dials into corresponding reading, it is convenient and easy working after installing these dials on each stations' two sides.

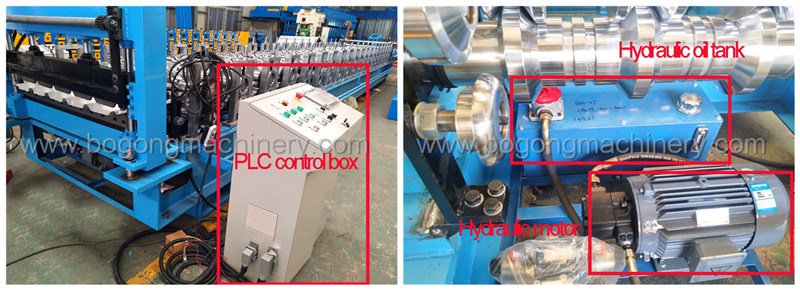

Normally, one set metal sheet roof roll forming machine will have on PLC control box, there is touch screen, inverter inside,all the working actions are controlled here, such as cutting off, speed adjusting,stop and start the producing line. The hydraulic motor is for controlling cutting off action,there is oil tank inside machine frame also, it can save space in factory site.

Technical Parameters

|

Parameters

|

Specification

|

|

Voltage

|

380V/50HZ/3PH/or customized

|

|

Driving Motor

|

7.5KW

|

|

Forming Steps

|

18 steps

|

|

Working Speed

|

15-20m/min

|

|

Thickness for Steel

|

0.25-0.4mm (Material:PPGI,GI Steel G550)

|

|

Shaft Diameter

|

75mm

|

|

Shaft Material

|

High grade 45# forged steel

|

|

Roller Material

|

G45# steel, CNC lathe,polished and chrome plated

|

|

PLC Cabinet

|

Schneider, Delta

|

|

Encoder

|

Omron

|

|

Sprocket Wheel

|

45 steel high-frequencies quench

|

|

Cut-off System

|

Post cutting, no waste cutting

|

|

Cutting Blade Material

|

Cr12 steel

|

|

Machine Frame Material

|

Fine welded structural steel;

|

|

Roofing Material

|

PPGI, GI steel G330-550

|

|

Painted Color

|

Blue+Orange Or Customization

|

|

Overall Size

|

9400*1450*1650mm

|

|

Weight

|

6500KGS

|

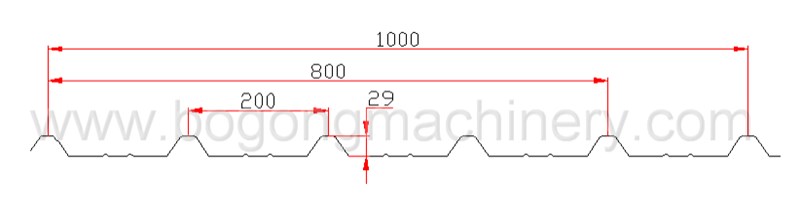

Profile Design Drawing

Raw material thickness: 0.25-0.4mm, raw material width: 1220mm, suitable for pre-painted steel coil, galvanized steel coil.

Need customized any type of roll forming machines, contact us immediately.