Professional customized design/manufacture kinds of roll forming machines

Product Name: Trapezoidal Galvanized Steel Roofing Sheet Roll Forming Machine

At the beginning end of this trapezoidal galvanized steel roofing sheet roll forming machine, we have made entry bench before pre-cutter. After the raw material come from uncoiler, the material passed by entry bench to avoid material block, it is the good middle passer between uncoiler and roll forming machine section, it also can match both automatic uncoiler and roll forming machine section's feeding speed well.

After entry bench, there is one set manual pre-shear, used for cutting no used material head and tail, the operator pull the pre-shear's hand rod, then finish.

In order to keep worker's safety, the pull-push protection cover is there. It is grid type, operator can see the trapezoidal galvanized steel roofing sheet roll forming machine's working state by eyes at the same moment. Each piece of cover is movable, can be pushed to each position if any maintenance is needed.

Working state indicator is another new safety design of ours, after we switch on the power supply, this indicator will be light. It can remind staffs work more carefully after seeing the indicator is light, also good for reminding staffs switch off the power supply after been off duty every day.

This metal roof sheet roll forming machine adopts stand pillar machine frame type, compare to traditional machine frame, it is good for user to maintenance whole roll forming machines, we can add lubricated oil any time, no need remove the gear cover again. Whole trapezoidal roof sheet roll forming machine with stand pillar machine frame looks more beautiful.

Technical Parameters

|

Parameters

|

Specification

|

|

Voltage

|

380V/50HZ/3PH/or customized

|

|

Driving Motor

|

7.5KW

|

|

Forming Steps

|

17 steps

|

|

Working Speed

|

15-20m/min

|

|

Thickness for Steel

|

0.3-0.72mm (Material:PPGI,GI Steel G550)

|

|

Shaft Diameter

|

75mm

|

|

Shaft Material

|

High grade 45# forged steel

|

|

Roller Material

|

G45# steel, CNC lathe,polished and chrome plated

|

|

PLC Cabinet

|

Schneider, Delta

|

|

Encoder

|

Omron

|

|

Sprocket Wheel

|

45 steel high-frequencies quench

|

|

Cut-off System

|

Post cutting, no waste cutting

|

|

Cutting Blade Material

|

Cr12 steel

|

|

Machine Frame Material

|

Fine welded structural steel;

|

|

Roofing Material

|

PPGI, GI steel G330-550

|

|

Painted Color

|

Blue+Orange Or Customization

|

|

Overall Size

|

9400*1450*1650mm

|

|

Weight

|

4500KGS

|

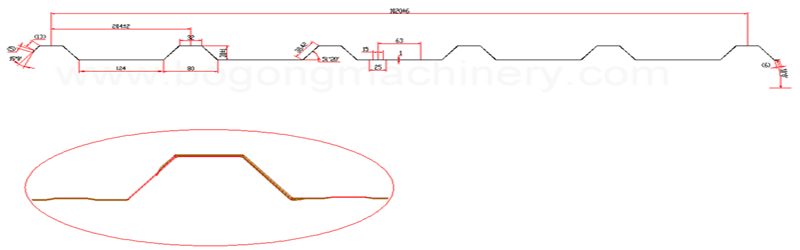

Profile Design Drawing

The raw material width for this roofing sheet is 1220mm, and the working thickness is from 0.3mm- 0.7mm, this is one of the popular roofing sheet roll forming design in Philippines.

Metal Roofing Sample And Machine appearance