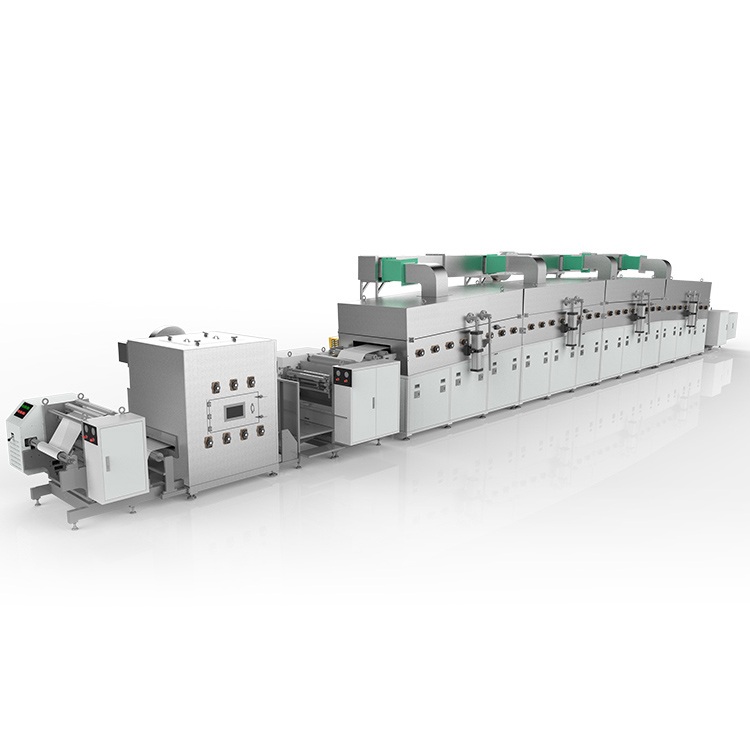

Diaphragm Coating Machine with Touch Screen Interface for Production Line

|

NO.

|

Project

|

Technical Parameters

|

|

1

|

Process adaptability

|

Lithium battery separator coating

|

|

2

|

Coating method

|

Continuous coating

|

|

3

|

Rewinding volume configuration

|

Single-axis / dual-axis manual roll change

|

|

4

|

Substrate processing

|

Preheating oven/ironing roller (surface leveling)

|

|

5

|

heating method

|

Electric heating / steam heating / oil heating

|

|

6

|

Oven configuration

|

Curved active over roller, length optional

|

|

7

|

Mechanical speed

|

Coating speed +10%

|

|

8

|

Coating speed

|

50m/min, 80m/min, 100m/min (depending on the model)

|

|

9

|

Coating width

|

00mm、900mm、1200mm

|

|

10

|

Coating thickness

|

--

|

|

11

|

Thickness accuracy

|

±0.5μm (when the coating thickness is greater than 1um)

|

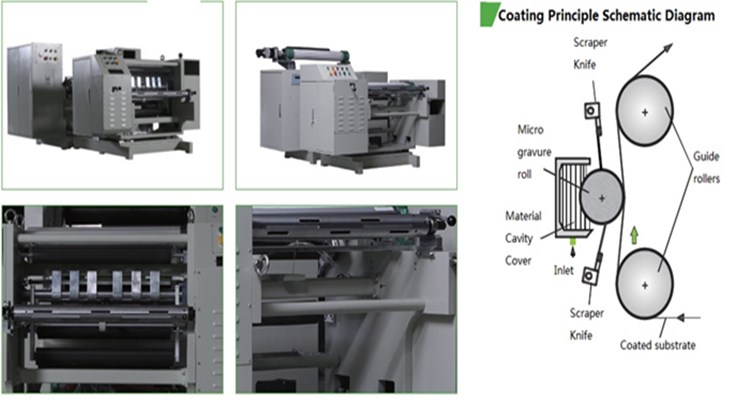

Advantage

1. System controlling is make it easy to operate, and the touch screen interface is simple and easy to understand.

2. Pendulum roller structure and closed loop tension control system to achieve low tension operation

3. The problem of substrate irregularity can be treated by preheating oven, and the scope of use of equipment can be improved.

4. The Fourth of company's research and production of closed cavity, scraping uniform, cleaning and replacement convenience.