DIN PN16 Cast Iron Ball Check Valve

Check valve is also called reverse flow valve, check valve, back pressure valve, check valve.This kind of valve depends on the flow of the medium itself in the pipeline and automatically open and close the force, belongs to a kind of automatic valve.

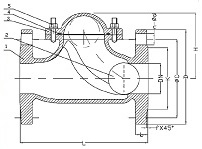

Ball check valveis a kind of multi-ball, multi-flow, multi-cone inverted fluid structure of the check valve, mainly by the front and rear valve body, rubber ball, cone body composition.

Check valve is used for the pipeline system when the medium downstream open, counter-current closed automatic valve, the main role is to prevent the medium backflow, pump and drive mechanical reversal, prevent the pump and drive motor suddenly stop running when the water hammer wave, reduce the damage to the pipeline system.Check valve can be divided into five categories: lifting type, swing type, dish type, diaphragm type and ball type check valve according to the relative displacement mode of the closing piece and seat.For the above check valves, most of the following disadvantages: when closed due to the water hammer effect of the "bang" and vibration;Due to the valve plate vibration, the "joint part" shaft and shaft sleeve in the valve produce mechanical friction motion, when the valve plate vibration frequency is too high, the shaft and shaft sleeve will produce mechanical friction motion, valve plate displacement, sealing failure, sometimes cause the valve plate fall off, so that the system protection failure;The fluid flow state in the valve is disordered, the flow resistance loss is big, the energy loss is serious, etc.In order to avoid and improve the above shortcomings, ball check valve with its good sealing, minimal flow resistance and other performance advantages, has been widely used and promoted, its structure from the initial "single ball" check valve gradually improved to the "independent multi-flow multi-ball" check valve.

Application

|

|

Design according to

|

EN558-1 sERIES 48;DIN3202 F6

|

|

Work pressure

|

PN16

|

|

Face to face

|

EN1092-2 PN10/16;ANSI B16.1 Class1125

|

Material Of Main Parts

|

1

|

Body

|

Cast Iron

|

|

2

|

Ball

|

NBR rubber-coated steel ball

|

|

3

|

Cover

|

cast iron

|

|

4

|

"O" Ring

|

NBR

|

|

5

|

Connecting Bolts

|

Stainless steel A2

|

Main Dimensions

|

|

Size

|

L

|

DN

|

K

|

C

|

D

|

H

|

f

|

b

|

n

|

d

|

|

50

|

206

|

48

|

98

|

125

|

155

|

103.5

|

2

|

19.5

|

4

|

18

|

|

65

|

238

|

63

|

110

|

145

|

181

|

126

|

2

|

19

|

4

|

18

|

|

80

|

243

|

78

|

132.5

|

160

|

193

|

150

|

2

|

20

|

8

|

18

|

|

100

|

295

|

98

|

161

|

180

|

232

|

181

|

2

|

20.5

|

8

|

18

|

|

125

|

347

|

119.1

|

190.5

|

210

|

257

|

218.5

|

2.5

|

23.5

|

8

|

18

|

|

150

|

394.5

|

140.2

|

213

|

240

|

282

|

256.5

|

2.5

|

23.5

|

8

|

22

|

|

200

|

498

|

198

|

274.5

|

295

|

346

|

334

|

3

|

27

|

12

|

22

|

Packing & Delivery :

Packing Details : all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details : Generally it is 5-10 days if the goods are in stock. or 15-30 days if the goods are OEM or not enough

subject to the order quantity. But anyway,normally, we are able to make sure the delivery will not exceed 45 days.