Any custom design/style are acceptable, provide OEM/ODM service

Product Name: Double layer Roofing Sheet Roll Forming Machine 915mm Raw Material Width

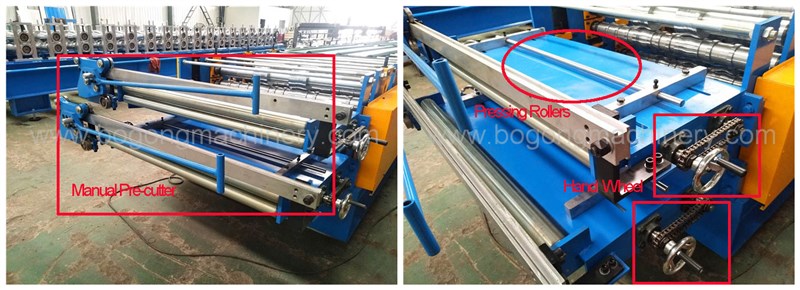

This roll forming machine is double layer types for producing roofing sheet, at the beginning end of whole line, there is manual pre-cutter for the two roofing designs, one layer one manual pre-cutter. we have designed hand wheels at two sides of machine frame, it is for adjusting raw material width more convenient. When we want to change machine to produce another material width, loosen the screw nuts on strips top at first, then operate the hand wheel to adjust the width strips at correct position, then lock the screw nuts again on the top of strips.

One pressing rollers on feeding table is for compacting material down and ensure material head can go into main double layer roofing sheet roll forming machines.

This is the double layer roofing sheet roll forming machine, we need two cutting blades for each profile design, to avoid any accident happen, we have installed safety limited switch on machine cutting end. Our hydraulic cutting section choose gear guider type, matched with double cylinders to ensure power balance, this can ensure cutting effect more better and extend whole cutting section working life

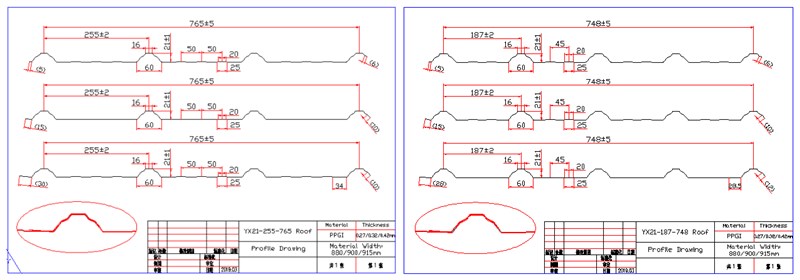

Profile Design Drawing

Each roofing design has three raw material width: 880mm, 900mm and 915mm and the effective width is 765mm and 748mm, material thickness is 0.27-0.5mm, for pre-painted steel coil only. If user need double layer roof panel roll forming machine for other material thickness or other material, we can custom design as requirements also.

Technical Specification

|

Parameters

|

Specification

|

|

Voltage

|

380V/50HZ/3PH/or customized

|

|

Driving Motor

|

15KW*2

|

|

Forming Steps

|

16 steps for upper layer, 17 steps for bottom layer

|

|

Working Speed

|

15-20m/min

|

|

Thickness for Steel

|

0.27-0.42mm (Material:PPGI,GI Steel G550)

|

|

Shaft Diameter

|

75mm

|

|

Shaft Material

|

High grade 45# forged steel

|

|

Roller Material

|

G45# steel, CNC lathe,polished and chrome plated

|

|

PLC Cabinet

|

Schneider, Delta

|

|

Encoder

|

Omron

|

|

Sprocket Wheel

|

45 steel high-frequencies quench

|

|

Cut-off System

|

Post cutting, no waste cutting

|

|

Cutting Blade Material

|

Cr12 steel

|

|

Machine Frame Material

|

Fine welded structural steel;

|

|

Roofing Material

|

PPGI, GI steel G330-550

|

|

Painted Color

|

Blue+Orange Or Customization

|

|

Overall Size

|

9500*1450*1650mm

|

|

Weight

|

7000KGS

|

Remark: YX21-255-765 roof is on upper layer, 16 steps roll forming; YX21-187-748 roof is on bottom layer, 17 steps roll forming.

Roof Sample and whole double layer roofing sheet roll forming machines.

Need to buy double layer roofing sheet roll forming machines? Contact with us soon, we can customized for you as you want!