Customize all special designs of steel roof sheet, metal doors, floor deck roll forming machines.

Product name: Steel Metal Roofing Sheet Dual Level Roll Forming Machine

Machine Details

The two layers of this Steel Metal Roofing Sheet Dual Level Roll Forming Machine can not work on the same time, so we have designed the manual clutch for changing working layer, we can see machine inside structure, the mechanical theory principle is: there are worn-gears aside the driving motor, when the bottom layer worn gear working together with motor, the bottom layer is running, or the upper layer is working.

Because this is dual level type Steel Metal Roofing Sheet Roll Forming Machine, so there are two feeding tables, two feeding table can ensure each layer's working height are the same, it is good for solving material block.

Due to this Steel Metal Roofing Sheet Dual Level Roll Forming Machine is longer than 12 meters, in order to solve loading shipping container problem, we break on machine into two section and jointed with screws and nuts on machine frame two sides.

Roof sheet sample after roll formed by Steel Metal Roofing Sheet Dual Level Roll Forming Machine before cut off, roof surface is no scratch and the roof sides are smooth.

Technical Specification

|

Parameters

|

Specification

|

|

Voltage

|

380V/50HZ/3PH/or customized

|

|

Driving Motor

|

11KW

|

|

Forming Steps

|

21 steps for upper layer, 22 steps for bottom layer

|

|

Working Speed

|

15-20m/min

|

|

Thickness for Steel

|

0.7-1.0mm (Material:PPGI,GI Steel G550)

|

|

Shaft Diameter

|

75mm

|

|

Shaft Material

|

High grade 45# forged steel

|

|

Roller Material

|

G45# steel, CNC lathe,polished and chrome plated

|

|

PLC Cabinet

|

Schneider, Delta

|

|

Encoder

|

Omron

|

|

Sprocket Wheel

|

45 steel high-frequencies quench

|

|

Cut-off System

|

Post cutting, no waste cutting

|

|

Cutting Blade Material

|

Cr12 steel

|

|

Machine Frame Material

|

Fine welded structural steel;

|

|

Roofing Material

|

PPGI, GI steel G330-550

|

|

Painted Color

|

Blue+Orange Or Customization

|

|

Overall Size

|

14500*1450*1650mm

|

|

Weight

|

11000KGS

|

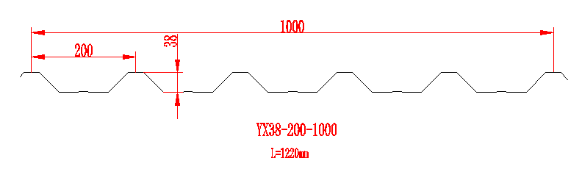

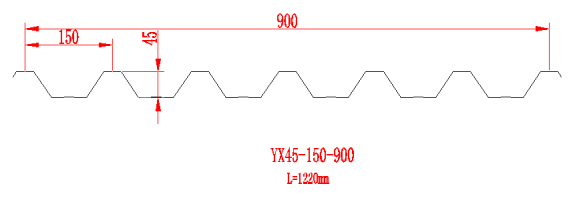

Remark: YX38-200-100 roof is on upper layer, 21 steps roll forming; YX45-150-900 roof is on bottom layer, 22 steps roll forming.

Roof Sheet Design

Suit for Pre-paint Coil,0.7mm Minimum Thickness, 1.0mm Maximum Thickness, The raw material 0.7mm steel sheet for inspection, in common use, Grade: G450.