The advantage of roof panel machine are as follows:

1.We are the first and only factory who have a whole Baking Finishing Line to treat the spare parts

2.Low cost, light weight but high strength, short building period, and re-cycle use

3.With computer controlled system which easy to operate and save time and material

4.Metal roof panel or sheeting features light weight, durability, recyclability, etc.

We also offer customized size.

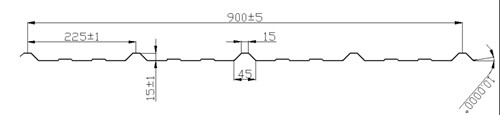

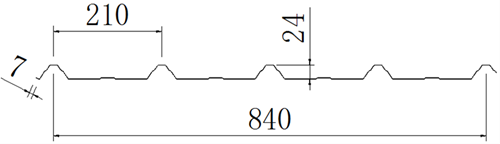

Profile drawing

Machine parts

1.Roof panel machine pre-cutter

With feeding material guide, avoid wasting material

2.Roof panel machine rollers

Rollers manufactured from high quality 45# steel, CNC lathes, heat treatment.

With black treatment or hard-chrome coating for options

Body frame made from 350#H type steel by welding.

3.Roof panel machine post cutter

Made by high quality mold steel Cr12 with heat treatment

Cutter frame made from high quality 20mm steel plate by welding

Hydraulic motor: 4KW

Hydraulic pressure range: 1-16Mpa

4.Roof panel machine protection cover

5.Uncoiler

Manual dedoiler: 1 set

Un-powered, manually control steel coil inner bore shrinkage and stop

Max.feending width: 1200mm, coil id range 508mm±30

With 7 tons hydraulic uncoiler for option

6.Exit rack

Un-powered, three units