SAT Epoxy Resin

Amorphous Toroidal Core and C Cut Core

SAT epoxy resin amorphous toroidal cores and amorphous metal cut cores performs high quality and low loss for both one Phase and three Phase distribution transformer as per customer’s specification by using SAT amorphous metal alloy made by SAT spray ribbon machine. SAT epoxy resin amorphous toroidal cores and amorphous metal cut cores are more effective for distribution transformers than silicon steel sheets. SAT amorphous metal core is ideally suited for renewable energy applications such as wind, farm and solar power.

The Specification

of Epoxy Resin Magnetic Toroidal Cores

|

Core design

|

Toroidal core

|

|

Core for common mode choke

|

10.78.24.5

|

|

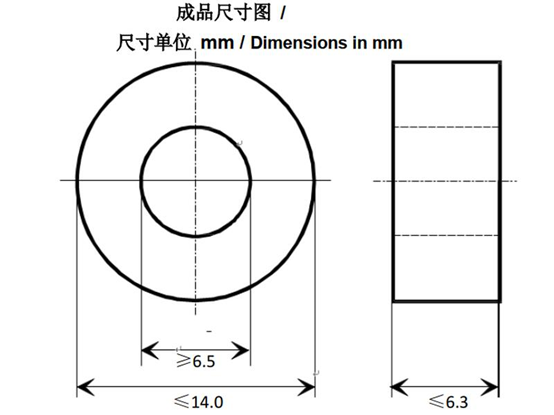

Nominal Dimensions

|

10.7x8.2x4.5mm

|

|

Core Material

|

SATG1K101

|

|

Type of Finish

|

Plastic box / silicon rubber

|

|

Rated Dimensions

|

Afe=0.045cm²

lFe=2.97cm

mFe=1.0g

|

|

Final Inspection

|

Magnetical Test Measurement at room temperature (AQL 0,65)

Inductance test without DC-magnetisation

|

|

7.1. MATS-2010A/ Measurement of core losses according

to MATS-2010A

Setting values:

B=400mT

F=50KHz

Specified value

pFe≤120 W/kg

7.2. MATS-2010S /Measurement of flux density swing

from residual flux density into saturation with unipolar rectangular voltage

pulses, constant field strength amplitude.

Setting values:

td = 20 µs,

fP = 1 kHz

H = 2A/cm

Specified values:

Br/Bs ≥0.8

|

Epoxy Resin

Amorphous Toroidal Core Features:

1. 70% lower core

loss compared to ferrite and silicon steel cores.

2. Lower hysteresis and eddy current losses, higher permeability.

3. Better overload capacity.

4. Environment friendly, lower carbon dioxide emission due to the lower demand

in generation.

5. Lower total cost of manufacturing due to the SAT Zero-Waste Eco

Technology.

6. Short circuit strength increasing due to the tape-wound construction.

7. Smaller size, easier to assemble and repair.

Please leave a

message below for more details of amorphous toroidal cores and

c cores product information.