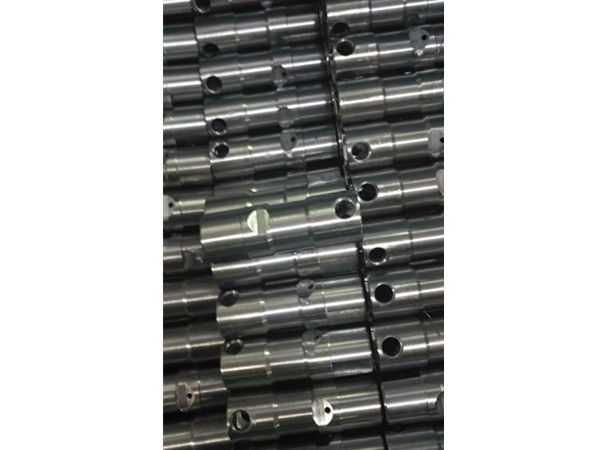

Flexible Die Making Gas Drilling Tapping Milling Machine

Main configuration:

Taiwan new generation bus system/nanjing da feng system

Synchronous high-speed spindle

High pressure cooling water pump

Taiwan silver roller rail/Yintai roller line rail

Three axis absolute value servo motor

Mobile electronic handwheel

Lube rundown system

BT30 spindle

Resin sand casting

Clip arm lotus knife bank

Skip ball screw rod/upper silver ball screw rod

Main electrical components France schneider

USB interface

Fully enclosed processing area

|

Maximum hole diameter

|

mm

|

Φ20/Φ30

|

|

Maximum tapping diameter

|

mm

|

M16/M22

|

|

Maximum milling cutter diameter

|

mm

|

Φ80

|

|

Spindle speed

|

rpm

|

10-8000

|

|

Spindle motor power

|

kw

|

3.7/7.5

|

|

The spindle taper hole

|

mm

|

BT30

|

|

Boring accuracy

|

mm

|

±0.01

|

|

Precision milling round

|

mm

|

±0.01

|

|

Tool change time

|

second

|

1-1.6

|

|

X,Y,Z axis repeat positioning accuracy

|

mm

|

±0.01

|

|

Table travel: X,Y,Z axis

|

mm/min

|

600X400X420

|

|

The table moves quickly: X,Y,Z axis

|

mm

|

36000

|

|

Distance between the working table and the main shaft

|

mm

|

150-600

|

|

Table size

|

mm

|

1200X420

|

|

Table t-slot

|

mm

|

3-18X140

|

|

Three axis servo motor power

|

kw

|

X:1.8 Y:1.8 Z:2.6

|

|

Three - axis join mode

|

|

Straight league

|

|

Three axis ball screw specification

|

|

X:3210 Y:3210 Z:4010

|

|

Three - axis linear guide specification

|

mm

|

X:35 Y:35 Z:45

|

|

Cooling water pump power

|

kw

|

0.55

|

|

Machine size

|

mm

|

2200X2200X2400

|

|

Machine tool gross weight

|

kg

|

≈3600

|

|

Maximum load weight of the table

|

kg

|

≈400

|

Our Serviece:

Before sales

Our professional technical recommend the right machine,and can also customise special machine as customer's requirement and special parts.

Sales following

During machine production, watching the machine quality and testing machine.and take pictures or make video for customer checking.

After Sales

We will send technical go to customer's factory to install and adjust machine.

We have after-sell service to supply all life-time machine maintance and repairment service.

FAQ:

Q: Are we a trading firm or a manufacturer?

A: We are a MANUFACTURER.

Q: What’s our payment mode?

A: L/C, T/T

Q: Can machines be customized?

A: YES.

Q: How long is the warranty period?

A: 12 months.