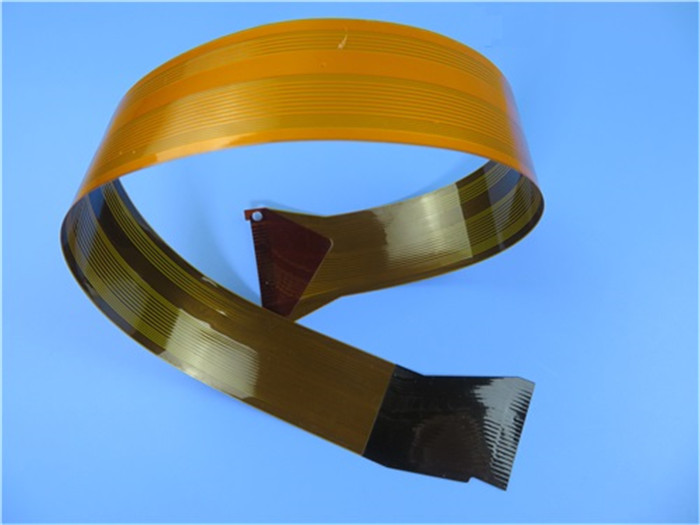

Flexible

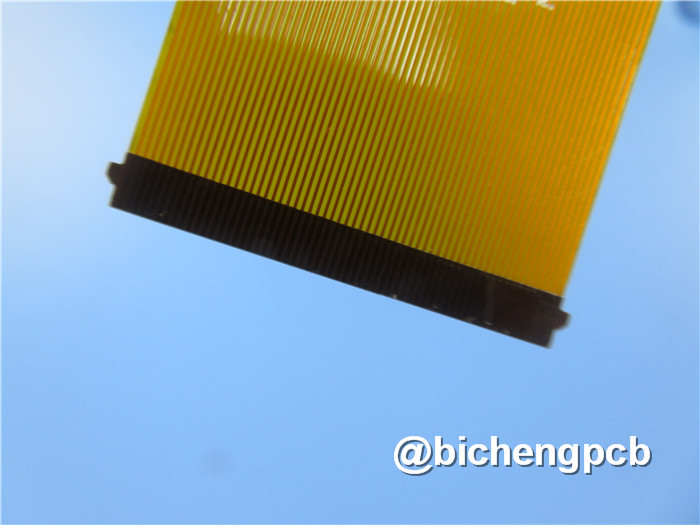

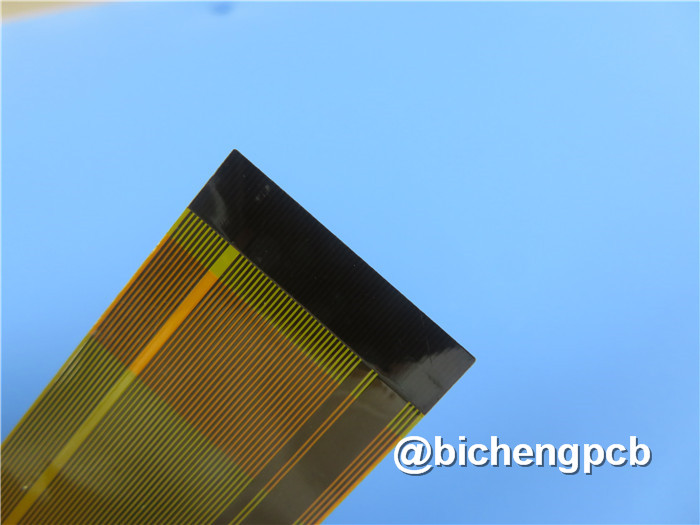

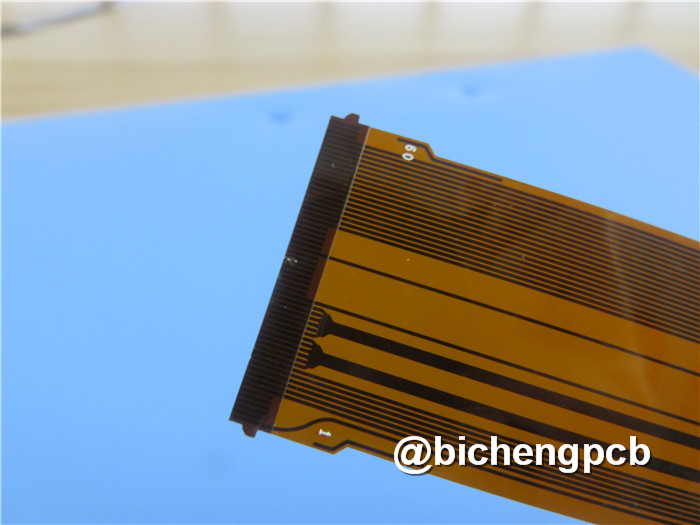

PCB with Polyimide Stiffener Flexible Printed Circuit (FPC) with PI Stiffener

(FPC’s

are custom-made products, the picture and parameters shown are just for

reference)

General

description:

The base laminate is from Shengyi, It’s

fabricated per IPC 6012 Class 2 using supplied Gerber data. Polyimide stiffener is applied on the inserting head.

Parameter

and data sheet:

|

Size of

Flexible PCB

|

230.5 X

40.8mm

|

|

Number of Layers

|

1

|

|

Board Type

|

Flexible PCB

|

|

Board Thickness

|

0.20mm

|

|

Board Material

|

Polyimide

(PI) 25µm

|

|

Board Material Supplier

|

ITEQ

|

|

Tg Value of Board Material

|

60℃

|

|

|

|

PTH Cu thickness

|

≥20 µm

|

|

Inner Iayer Cu thicknes

|

N/A

|

|

Surface Cu thickness

|

35µm (1oz)

|

|

|

|

Coverlay Colour

|

Yellow

|

|

Number of Coverlay

|

1

|

|

Thickness of Coverlay

|

25

µm

|

|

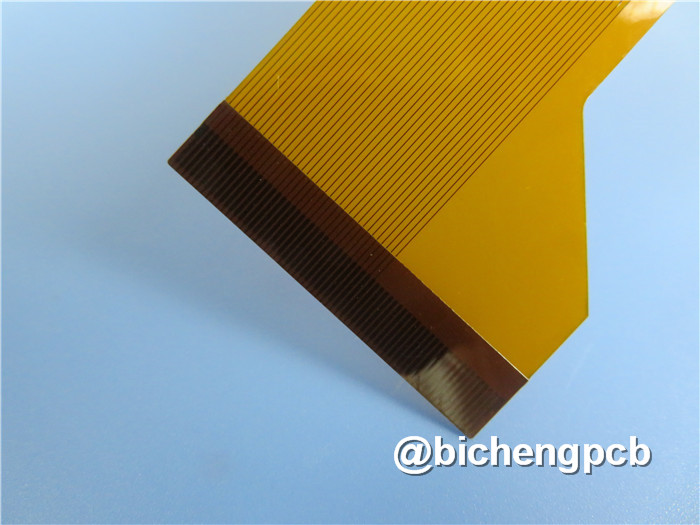

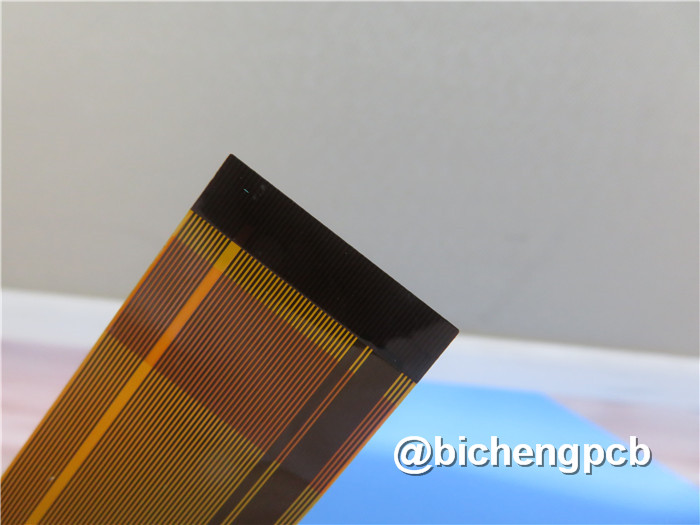

Stiffener Material

|

Polyimide

|

|

Stiffener Thickness

|

0.2mm

|

|

|

|

Type of Silkscreen Ink

|

IJR-4000

MW300

|

|

Supplier of Silkscreen

|

TAIYO

|

|

Color of Silkscreen

|

White

|

|

Number of Silkscreen

|

1

|

|

|

|

Peeling test of Coverlay

|

No

peelable

|

|

Legend Adhesion

|

3M 90℃No

peeling after Min. 3 times test

|

|

|

|

Surface Finish

|

Immersion

Gold

|

|

Thickness of Nickle/Gold

|

Au:

0.03µm(Min.); Ni 2-4µm

|

|

RoHS Required

|

Yes

|

|

Famability

|

94-V0

|

|

|

|

Thermal Shock Test

|

Pass, -25℃±125℃, 1000 cycles.

|

|

Thermal Stress

|

Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering.

|

|

Function

|

100%

Pass electrical test

|

|

Workmanship

|

Compliance

with IPC-A-600H & IPC-6013C Class 2

|

Features

and benefits:

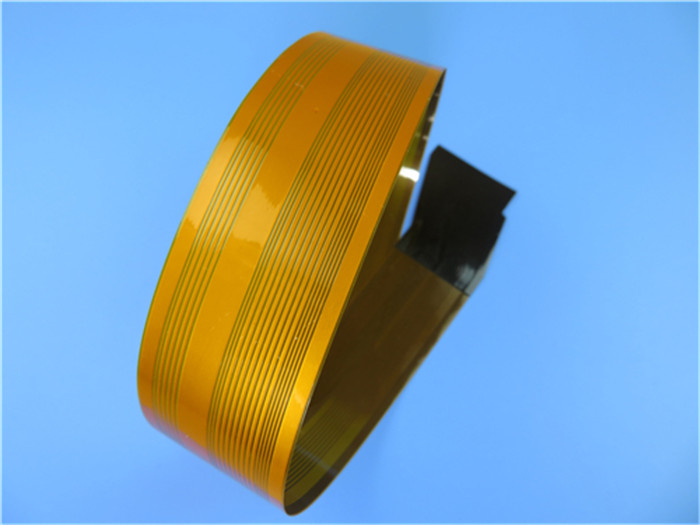

Excellent

flexibility

Reducing

the volume

Weight

reduction

Consistency

of assembly

Increased

reliability

Low

cost

Continuity

of processing

Focus

on low to medium volume production

More

than 18 years of experience

Applications:

Mobile

phone built-in antenna FPC, flex keyboard for mobile phone keys, Industrial

control computer soft board

Stiffener:

In

many applications where there are components soldered, the flexible boards require

external stiffeners (Stiffener, also known as the reinforcing board) for

external support. The stiffener materials are PI or Polyester film, glass

fiber, polymer materials, steel foil, aluminum shim and so on.

(1)PI

or Polyester

PI

and polyester films are commonly used stiffener materials for flexible circuit

board. The commonly used thickness is 125μm (5mil), some hardness can be

obtained.

(2)Glass

fibers

Glass

fibers (such as FR-4), which are also commonly used materials for stiffeners.

The fiber glass stiffener has a higher hardness than that of PI or Polyester,

used where the requirements of harness is higher. The thickness range is

typically 125μm (5mil) to 3.175mm (125mils). However, its processing is

relatively difficult than PI, and may not be a standing material for some FPC

factories.

(3)Polymer

Polymer,

such as plastic, etc. is also used as stiffeners.

Its

water absorption is low, with high pressure and high temperature resistance.

(4)Steel

foil, aluminum shim

The support

hardness of steel foil, aluminum shim is high, the heat can also be dissipated.

The hardness or heat dissipation in the design is the main concern.

More

Displays of PI Stiffener:

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS: