Bonve rotary Lobe Pumps for Ketchup

Ketchup is a sauce-like concentrated

product of fresh tomatoes. It has a bright red sauce and a unique flavor of

tomato. Ketchup is made up of ripe red tomatoes after being crushed, beaten,

and peeled off, such as skin and seeds, and then concentrated, filled, and

sterilized. Ketchup is often used as a cooking ingredient for fish, meat and

other foods. It is a seasoning for color, acid, fresh and fragrant.

The problem

With the dramatic increase in hygiene and safety standards in the tomato paste / suace/ Ketchup sector, higher demands are placed on pumps that are found throughout the production process:

Soft delivery, cleansing and sterility

The entire process must be hygienic

Safe operation and easy maintenance

The solution

Bonve food grade rotary lobe pumps are designed to transfer low, medium and high-viscosity liquids if the food industry, including tomato liquid products. The pumps are widely used and recognized because of below features.

Hygienic material

All wetted metal parts are made of SS304, SS316 or SS316L. The elastic material is nitrile rubber, fluororubber, ethylene propylene rubber, polytetrafluoroethylene, and the like.

Gentle, hygienic design

High precision rotor and low shear operation ensure gentle movement of the delivered product.

Modular pump design

The modular design increases the flexibility and interchangeability of the components, and is easy to install and maintain, with less wearing parts; high efficiency and low failure rate.

Easy to drain

Vertical port designed easy to drain, no material residue.

Multiple seal type design

According to the different characteristics of the medium, the correct sealing form is used to ensure zero leakage and no pollution.

CIP & SIP

Suitable for CIP (clean in place) and SIP (disinfected in place) applications.

High precision manufacturing

Pump working parts are machined by CNC machining center, the surface roughness is below 0.8μm, the inner cavity is smooth, no dead angle, and the medium is prevented from remaining.

Hygienic standard

Comply with EHEDG, 3-A standard.

Pump information

How pump works?

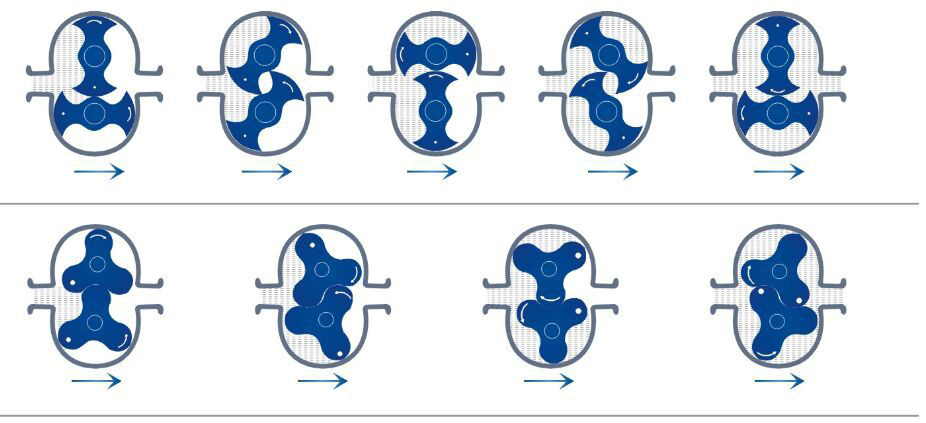

The even rotation of the rotor pair creates a vacuum on the

priming side of the pump, which can be defined by the direction of rotation of

the drive. This vacuum draws the liquid into the pump chamber. With further

rotation, the pumped medium is conveyed past the pump wall into the pressure

area. Up to six chamber charges are displaced with each drive rotation– depending on the rotor type. When the rotor is at a

standstill, the pump seals off almost

completely.

Pump

main structure

Pump

structure advantage

Pump main technical parameters

|

Model

|

Displace

-ment

(L/r)

|

Rotation

speed

(r/min)

|

Flow

rate

(M³/h)

|

Dis.

Pre.

(Mpa)

|

Electrical

power

(Kw)

|

Suc.

Pre.

(Mpa)

|

Dia.

of inlet and

outlet (mm)

|

|

25BV6 /12-2

|

0.15

|

20-600

|

2

|

0.1-1.2

|

1.1-2.2

|

-0.095

|

25

|

|

40BV6 /12-5

|

0.32

|

20-550

|

5

|

0.1-1.2

|

1.5-4

|

-0.095

|

40

|

|

50BV6 /12-10

|

0.65

|

20-550

|

10

|

0.1-1.2

|

2.2-7.5

|

-0.095

|

50

|

|

65BV6 /12-20

|

1.74

|

20-550

|

20

|

0.1-1.2

|

4-15

|

-0.095

|

65

|

|

80BV6 /12-30

|

2.48

|

20-550

|

30

|

0.1-1.2

|

5.5-22

|

-0.095

|

80

|

|

80BV6 /12-40

|

3.65

|

20-550

|

40

|

0.1-1.2

|

7.5-30

|

-0.095

|

100

|

|

125BV6 /12-50

|

4.60

|

20-550

|

50

|

0.1-1.2

|

11-45

|

-0.095

|

125

|

|

125BV6 /12-70

|

6.10

|

20-550

|

70

|

0.1-1.2

|

15-55

|

-0.095

|

125

|

|

125BV6 /12-80

|

7.63

|

20-550

|

80

|

0.1-1.2

|

18.5-75

|

-0.095

|

125

|

How

to choose ?

|

Selection Guideline

|

|

Liquid

name:___________

|

|

Viscosity:_______cp Density:_______

Temperature:_____℃ PH

value:________

|

|

Solid content:_______ Max. size of particle:_______

|

|

Capacity: Max. required__________ L/H Working required__________ L/H

|

|

Discharge pressure: Max. required__________Mpa Working required__________ Mpa

|

|

Connection type required: Thread [ ] Clamp [ ]

|

|

Installation type: Fixed [ ] Movable [ ]

|

|

Voltage:____ V Frequency: _____Hz

|

|

Liquid contact material: SS304 [ ] 316 [ ] 316L [ ]

|

|

Special request_____________________________________

|

|

Order qty.

|

Thanks

for your interest into our rotary lobe pump, hope we can solve your pumping

problem during your ketchup production. Contact our sales engineer - Mr. Andre

Chen for a pump solution.

Email: bvsales2@bonvepumps.com

Tel :

0086-574-87769810

Mobile: 0086-15888591452