Classifier Mill Brief Introduction

The machine is mainly suitable for crushing the material below 3.5 mohs hardness, it can obtain 8~150um super fine powder, and that the large flow cooling air can be used for heat sensitive materials.

Working principle

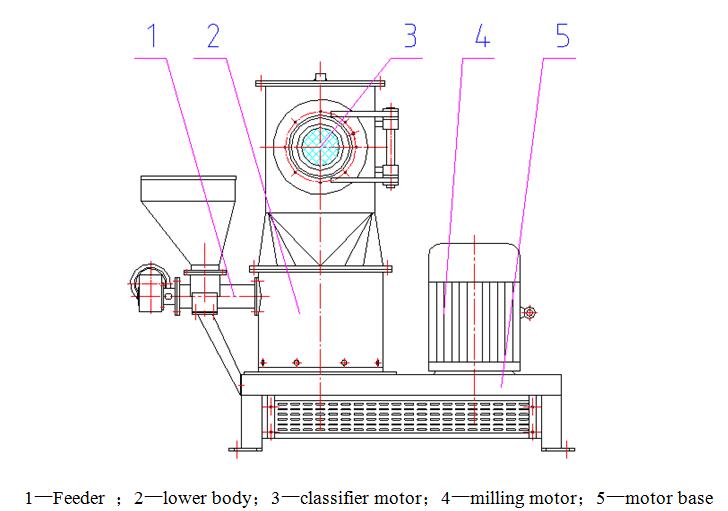

The body cavity is cylindrical, the upper part is an ultramicro classifier, and the lower part is an ultramicro grinder. The grinding chamber is made up of crushing discs and grinding blocks for material handling.

The classification chamber is made up of stepped impeller. It can divide fine powder into two specifications, one is qualified product and the other is failing to reach standard product.

The qualified product is collected by cyclone, the defective product fell back to the crushing chamber along the wall of the lumen and continued to crush until it reached the standard.

The grinding wheel and the grading impeller are respectively driven by their respective driving devices, and the speed of the grading impeller can be adjusted to adjust the particle size of the product. The spiral feeding device located in the inner wall of the machine body is used for evenly feeding material into the crushing chamber, and the charging quantity can be realized by adjusting the speed.

Characteristics

1. The machine is a two axle design, with built-in classifier to replace the screen of the traditional machine to adjust the fineness.

2. By adjusting the rotational speed of the grading impeller, the particle size of the product can be adjusted without stopping.

3. When the system is running,the strong air flow produces strong cooling function to avoid temperature rise. It is especially suitable for processing heat sensitive and fibrous materials. The granularity is uniform.

4. Bearing and drive belt adopt imported parts with long service life.

5. According to the characteristics of materials,machine is adopted professionally design in crushing parts and grading components . Machine is upgraded from a universal crusher to a special type of pulverizer to further improve the grind efficiency.

6. Apply to low to medium hardness (Mohs below 3.5) material crushing.

Technical Parameters

|

Model

Parameters

|

JCSM-100

|

JCSM-230

|

JCSM-315

|

JCSM-500

|

JCSM-630

|

|

Miller

|

Rotor Dia.(mm)

|

200

|

430

|

630

|

1000

|

1250

|

|

Power(kw)

|

5.5~7.5

|

15~22

|

30~37

|

55~75

|

75~90

|

|

Roation rate(r/min)

|

10000

|

4800

|

3280

|

2100

|

1650

|

|

Classifier

|

Rotor Dia(mm)

|

100

|

230

|

315

|

500

|

630

|

|

Power(kw)

|

1.5~3

|

4~5.5

|

7.5~15

|

15~22

|

22~37

|

|

Roation rate(r/min)

|

0~12000

|

0~6000

|

0~4000

|

0~2550

|

0~2000

|

|

Granularity

|

5~50

|

6~60

|

8~75

|

10~100

|

12~150

|

|

Capacity(kg/h)

|

5~100

|

20~500

|

50~1500

|

100~2500

|

150~3500

|

|

Aspiration Max (m3/h)

|

600

|

1800

|

2800

|

6000

|

9600

|

|

Weight(kg)

|

250

|

750

|

1600

|

3100

|

4500

|