Structure and working principle

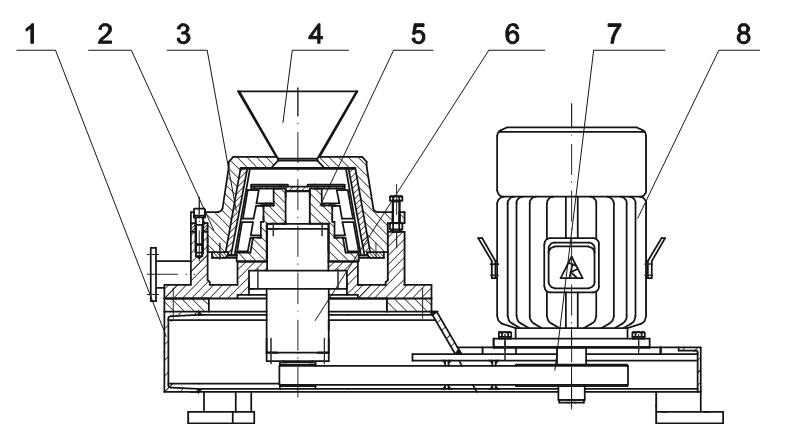

It consists of frame, body, turbo mill device, input hopper, transmission device and motor.

1—Frame;2—Body;3—Stator;4-Hopper;5—Rotor;6—Axle seat device;7—transmission device;8—Motor

The main working principle

after the material is added from the top of the upper box, it is quickly dispersed by the precomminuted blade on the upper part of the rotor and scattered to the four walls of the stator, then enter the comminuted area which consist of the rotor and stator. The large amount of air flow produced by the super high speed rotation of the rotor is influenced by both the rotating and static parts of the machine, and it is properly guided by the machine, and is transformed into a number of turbulence. The number of air turbulence in the crushing area increases the speed of the material and accelerates to the same speed as the air flow. However, the running direction and speed of these materials are suddenly changed .The result is the principle of the crusher. The particles collide each other and complete the ideal cracking in the high speed air. Only a small part of the particles is crushed by the internal motion and the stationary part. The material particles are always surrounded by air flow during the entire stay in the machine. Therefore, it is inevitable that production in the ultrafine grinding process is taken away by the air flow as the grinding medium. Large flow of air and its turbulence ensure minimum temperature rise.

To achieve the desired fineness and yield, the height of the gap gasket can be increased or reduced to change the clearance between the rotor and stator so as to control its output and fineness.

Performance characteristics

(1)、The clearance of the rotor and stator can be adjusted to control the fineness and output of the product.By using conical rotor and stator ,through rise or fall upper box (stator) to control the fineness and output of the product. The clearance adjustment range is 0 ~ 5mm.

(2)、The rotor adopts special high strength steel and high hardness wear-resistant castings imported from Europe. The velocity of the rotor is up to 125 meters per second, and it has a long service life.

Main technical parameters

|

Model

Name

|

JKTM250

|

JKTM500

|

JKTM750

|

JKTM1000

|

JKTM1250

|

|

Rotor Dia(mm)

|

250

|

500

|

750

|

1000

|

1250

|

|

Rotor rotation(r/min)

|

9550

|

4775

|

3183

|

2387

|

1910

|

|

Granularity(μm)

|

5~250

|

|

Aspration(m³/h)

|

1200

|

2100

|

3300

|

4500

|

5100

|

|

Capacity(kg/h)

|

30~800

|

80~2000

|

100~3000

|

200~4500

|

300~6000

|

|

Power(kw)

|

11~18.5

|

30~45

|

45~75

|

55~110

|

75~132

|

|

Weight(kg)

|

500

|

1100

|

2300

|

3000

|

3600

|