Roller Shutter Door Roll Forming Machine

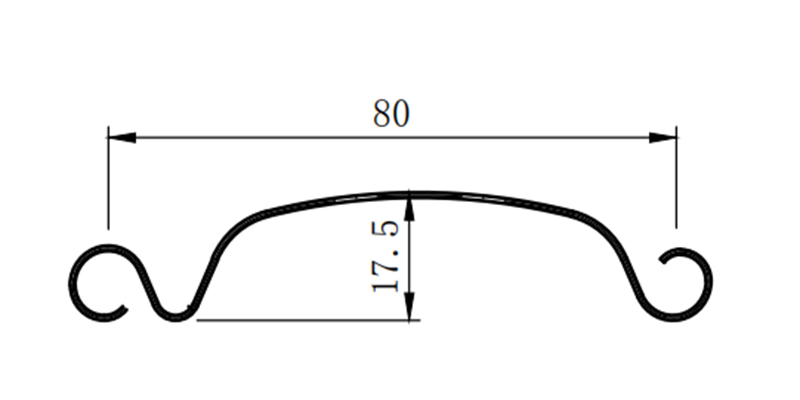

Profile

Material

Effective width:80mm

Feeding width: about 135mm

Material Thickness: 0.5-0.8mm;0.8-1.2mm

Applicable material:Galvanized Steel(GI),Cold Roll Steel(CRC)

With yield strengt :245-345Mpa

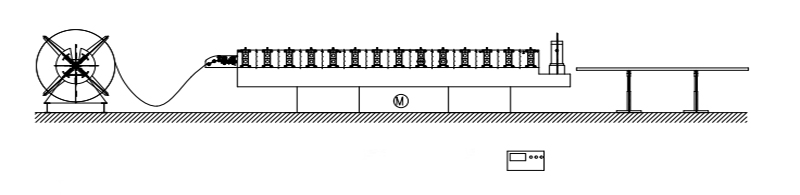

Work Follow

Decoiler→Feed Guide Device→Rolling Forming System→Leveling Device →Hydraulic Post Cutting Device→Exit Rack

Machine Components

1) 3 Ton Manual Decoiler: one set

Manual control steel coil inner bore shrinkage and stop

Max. feeding width:300mm,Coil ID Range:508±30mm

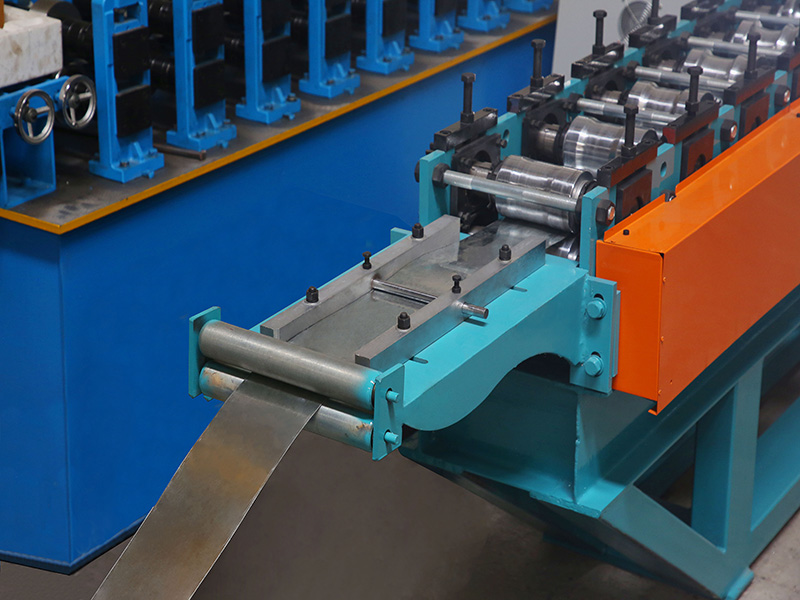

2) Feed Guide Device

A left and right guiding device at the main entrance of the machine. During work,Raw materials on both sides of the plate the enter into the machine by the left and right guiding device,make the raw materials and roll forming system to maintain the correct position. The guiding position can be adjusted by the manual screw mechanism,and the left and right can be adjusted independently.

3) Main Machine

body frame made from H400 type steel by welding

Side wall thickness: Q235 t18mm

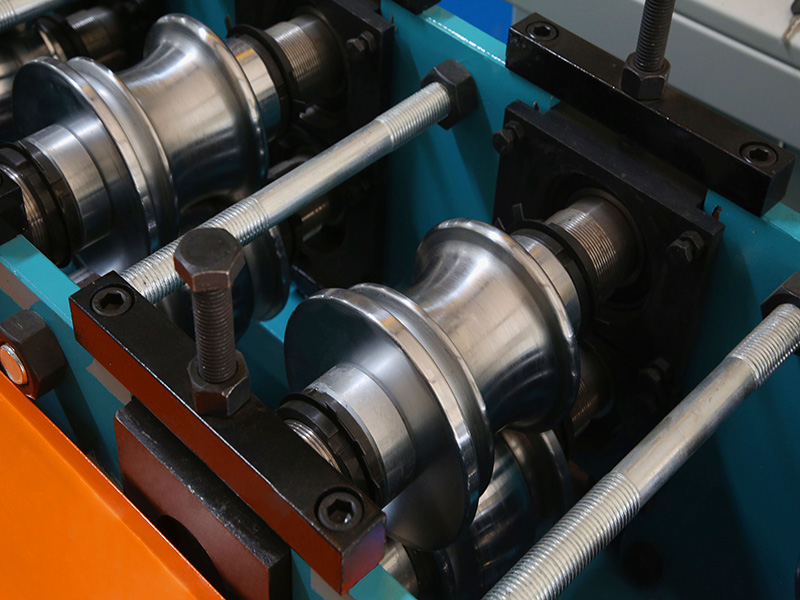

Rollers manufactured from 40Cr,CNC lathes,Heat Treatment,hard Chrome Coated,with thickness 0.04mm,surface with mirror treatment(for longer life and anti-rust)

Shafts Diameter=ф50mm,precision machined

Gear/Sprocket driving,about 14-step to form

Main Motor(Polaroid brand)=5.5KW,Frequency speed control

Speed redcucer motor:R series

Chain: ZIQIANG (by China TOP 1 brand DONGHUA Group)

Chain size: one inch with 18 teeth

All the screw bolts with grade 8.8(cheap factories use low grade 4.8) to ensure fix the machine structure tightly and long life during the machine long time running.

Real forming speed 0-20m/min(Not include cutting time and punching time

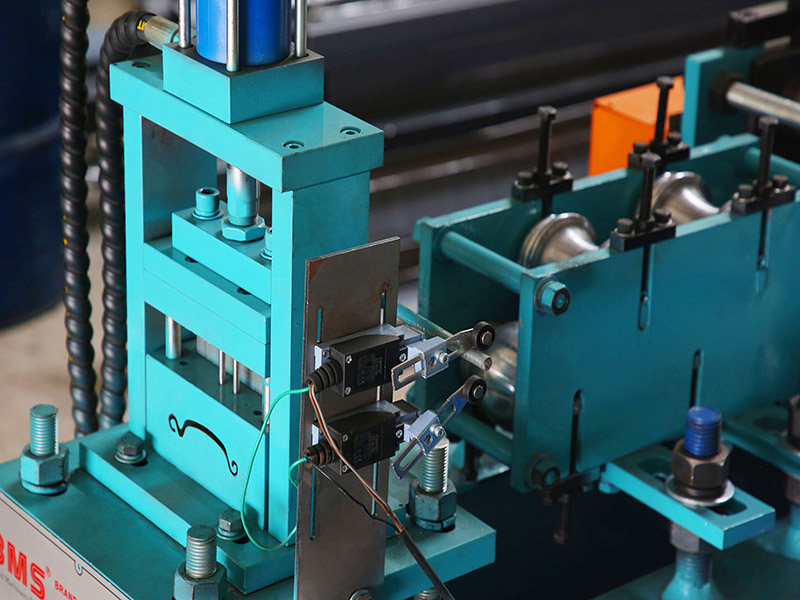

4)Leveling Device & Post Hydraulic Cutting Device(Include Punching)

Leveling device will make the product more beautiful

Hydraulic motor: 3KW;Cutting pressure: 0-16Mpa

Cutting tool material: Cr12Mov(= SKD11 with at least one million times of cutting life), Heat treatment to HRC58-62 degree

The cutting power is provided by the main engine Independent hydraulic station

5) PLC Control System

Control The Quantity And Cutting Length Automatically

Input The Production Data(Production Batch,pcs,Length,etc.)On The Touch Screen ,

It Can Finish The Production Automatically.

Combined With: PLC, Inverter, Touch Screen, Encoder, etc

6)Exit Rack

Un-powered, One units,with rollers on it for easy movement

After-Sale Service

1. The warranty is 24 months after the client receives the machine.

Within the 24 months, we will courier the replacement parts to the client free of charge

2. We offer technical support for the entire life of our machines

3. We can send our technicians to install and train the workers in the clients' factories with

extra cost

Terms Of Trade

1.Minimum order quantity (MOQ): 1 Set

2.Delivery time: about 45 workdays

3.Port of loading: port of Xiamen

4.Type of payment: by T/T or by L/C

5.Export:to more than 50 countries and regions, including Taiwan, UK, France, Singapore,

Greece, Australia, USA, Mexico, Brazil, Chile, Bolivia, Trinidad, Israel, Saudi Arabia, etc

Packing Style

Packing method: Main body of machine is naked and covered by plastic film(to protect of dust and corrosion),loaded into container and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.