Custom manufacture greenhouse gutter / greenhouse omega profile /greenhouse clip profile/greenhouse film steel fastener/ Wiggle wire film steel lock profile roll forming machine

Product name: High Speed Greenhouse Gutter Structure Roll Forming Machine

For this high speed greenhouse gutter structure roll forming machine, we have designed two guider sections at the beginning of whole roll forming lines. After galvanized steel coil goes into feeding rollers, the first feeding guider leans material go into straightening rollers, after straightening device, the second guiders working and lead flattened material into roll forming sections. The two guider sections width is adjustable.

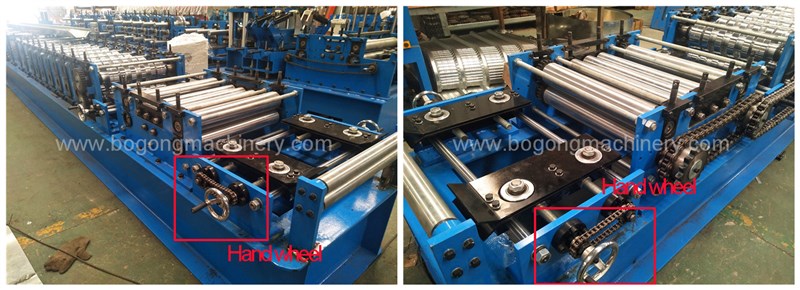

See below pictures for reference, the hand wheel we have marked out is for adjusting the feeding material width.Because as our experience, the steel coil width may be slitted a little different, some coil is wider and some is smaller, then we can adjust these hand wheels to suit for our high speed greenhouse gutter structure roll forming machine lines. There are two groups hand wheels on each guider section, total four sets, we only need adjust on side hand wheel on each guider section is it is necessary, because there are union combined.

The gutters cutting off action are finished by hydraulic system, it is blanking cutting, with small waste material to ensure cutting head is beautiful. This greenhouse gutter structure roll forming machine speed is adjustable, it can be adjust on PLC control box. The important for greenhouse structure product is to keep the gutter straight and the connecting position is smoothly, see below sample for reference.

Technical Parameter

|

Parameters

|

Specification

|

|

Voltage

|

380V/50HZ/3PH or customized

|

|

Driving Motor

|

11KW

|

|

Hydraulic Cuting Motor

|

3KW

|

|

Forming Steps

|

18 Station

|

|

Working Speed

|

15-20m/min

|

|

Thickness for Steel

|

15-2.0mm

|

|

Shaft Diameter

|

75mm

|

|

Shaft Material

|

High grade 45# forged steel

|

|

Roller Material

|

GCr15 steel with polished and heat treatment

|

|

PLC Cabinet

|

Schneider, Delta

|

|

Encoder

|

Omron

|

|

Sprocket Wheel

|

45 steel high-frequencies quench

|

|

Cut-off System

|

Pre-punch pre-cut

|

|

Cutting Blade Material

|

Cr12 steel

|

|

Machine Frame Material

|

Fine welded structural steel;

|

|

Roofing Material

|

PPGI, GI steel G330-550

|

|

Painted Color

|

Blue+black Or Customization

|

|

Overall Size

|

9000*1000*1450mm

|

|

Weight

|

4500KGS

|

Need More Information, pls contact: +86 15959271231 (whatsapp/ wechat ID also)