Ketchup is a sauce-like concentrated product of fresh tomatoes. It has a bright red sauce and a unique flavor of tomato. Ketchup is made up of ripe red tomatoes after being crushed, beaten, and peeled off, such as skin and seeds, and then concentrated, filled, and sterilized. Ketchup is often used as a cooking ingredient for fish, meat and other foods. It is a seasoning for color, acid, fresh and fragrant.

Tomato ketchup is a condiment manufactured from similar ingredients, although paste is used rather than whole tomatoes. Premium quality ketchup with a high solids content derive their viscosity from a combination of water retention of the fibrous strands in the paste and the gelling effect of pectin found naturally in tomatoes. High pressure homogenization is also used to obtain the desired viscosity.

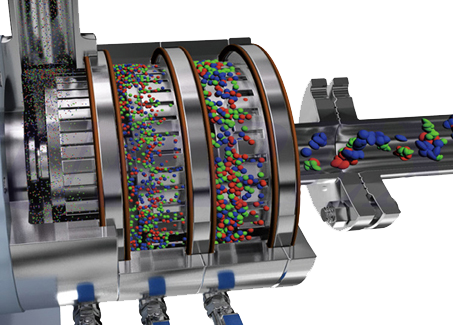

Bonve Homogenizer Mixer

Bonve Homogenizer Mixer is an efficient type machine with mixing, dispersion, breaking, dissolution, refinery, homogenization and emulsifying. It is an ideal machine to be instead of colloid mill, ball mill and high pressure homogenizer.The machine can greatly simplify the traditional productions and upgrade the production efficiency and product quality.

HOW IT WORKS?

The main parts are stators and rotors. At centrifugal and fluid forces created by rapid turning of the rotors, the stators exercise on the materials with strong power shearing, centrifugal pressing, breaking, fluid friction, turbulent. The processed materials (solid, fluid and gas phase) are quickly refined, homogenized, dis-aggregated and emulsified. The repeat of this process can result in stable and high-quality products.

MIAN TECHNICAL FEATURES

-Capacity: Self-pumping through puts of up to 100 T/H.

-No Bypassing: Product cannot bypass the precision rotor/stator work head.

-Work heads: Three stages rotors/stators.

-Materials of Construction: SS304, SS316 and 316L.

-Motor Specification: 2 or 4-ploe Motor. Standard power supply: 3ph, 380V, 50Hz.

-Inlet and Outlet Connections: Clamp connection as standard.

-Sealing: Double-face water flushed mechanical shaft seals as standard.

--Cleaning: All homogenizers are designed suitable for cleaning in place (CIP and SIP).

TECHNICAL PARAMETERS FOR REFERENCE

FHM1 series with One stage rotor and stator

|

Model

|

Electrical

Power

(Kw)

|

Rotation

Speed

(r/min)

|

Handling

Capacity

(m3/h)

|

Discharge

pressure

(Mpa)

|

Dia. of

inlet/outlet

(mm)

|

|

FHM1/140

|

5.5

|

2900

|

2

|

0.1

|

DN40/32

|

|

FHM1/165

|

7.5

|

2900

|

5

|

0.15

|

DN50/40

|

|

FHM1/185

|

11

|

2900

|

10

|

0.15

|

DN65/50

|

|

FHM1/200

|

15

|

2900

|

15

|

0.15

|

DN80/65

|

|

FHM1/220

|

22

|

2900

|

20

|

0.15

|

DN80/65

|

|

FHM1/240

|

30

|

2900

|

40

|

0.2

|

DN100/80

|

|

FHM1/260

|

37

|

2900

|

60

|

0.2

|

DN125/100

|

|

FHM1/300

|

45

|

2900

|

80

|

0.25

|

DN125/100

|

FHM3 series with Three stage rotors and stators, which has greater shearing and more efficieny

|

Model

|

Electrical

Power

(Kw)

|

Rotation

Speed

(r/min)

|

Handling

Capacity

(m3/h)

|

Discharge

pressure

(Mpa)

|

Dia. of

inlet/outlet

(mm)

|

|

FHM3/140

|

11

|

2900

|

5

|

0.2

|

DN40/32

|

|

FHM3/165

|

18.5

|

2900

|

10

|

0.3

|

DN50/40

|

|

FHM3/185

|

30

|

2900

|

20

|

0.4

|

DN65/50

|

|

FHM3/200

|

45

|

2900

|

30

|

0.5

|

DN80/65

|

|

FHM3/220

|

55

|

2900

|

40

|

0.5

|

DN80/65

|

|

FHM3/240

|

90

|

2900

|

60

|

0.6

|

DN100/80

|

|

FHM3/260

|

132

|

2900

|

100

|

0.6

|

DN125/100

|

SELECTION GUIDELINE

|

Medium's proportion

|

Liquid % ____ Density____ Viscosity____ PH value____

Solid % ____ Solid size ___

|

|

Processing requirement

|

Mixing dissolving ( ) Dispersed suspension ( )

Emulsification ( ) Homogeneity ( )

Reaction ( ) Powder liquid mixing ( )

|

|

Working type

|

Continuous circulation work ( )

Batch type ( )

|

|

Working temperature

|

|

|

Particle size

|

Before processing ____

After processing _____

|

|

Handling capacity required

|

|

|

Delivery head/pressure required

|

|

* For a quick quote, please email cathy@bonvepumps.com to ask form and fill. Thank you for your interest into our Homogenizer mixer for tomato sauce and ketchup.