Product Item:Hydraulic Punch Stamping Machine

1. Main Features:

1) Hydraulic Punching Machine use rigid rotating-key clutch, structure simple, easy operation and maintenance-free, driven by helical gear, stable, low impact.

2) J21S-25 open inclinable punching machines are the domestic first batch of punching machine equipped with ball bearings, high resistance and low noise, instead of traditional sliding bearing (copper tile).

3) J21S open-type inclinable punching machine is unique in the industry, copper tile transmission gear.

4) Redesigned frame with high strength, transmission through ball bearing (low noise)

5) All J21S-80T above punching machines: pneumatic double balancing cylinder structure balances the weight of slider and upper die to prevent shaking.

6)Hydraulic Metal Punching Machine Can prevent gear colliding, minimizing noise, eliminating the gap between connecting rod and slider, reducing impact and wear of loaded parts

7) Prevent the slider from falling down and occurring accident in case of brake failure or connecting-rod breaking down

2. Standard Accessories:

●China-made high performance motor

●France Schneider electrics

●Safety standard (2006/42/EC):

●Left and right safety fence

3. Safety Standards:

●Safety standard(2006/42/EC)

●Opening electric cabinet door cuts off power

●China-made pedal switch (safety grad: 4)

●Left and right safety fence confirm to CE standard

●Safety relay monitor pedal switch, safety protection

4. Technical Date:

|

ITEM

|

UNIT

|

J21s-25

|

J21s-45

|

J21s-60

|

J21s-80

|

J21s-125

|

|

Nominal Capacity

|

KN

|

250

|

450

|

600

|

800

|

1250

|

|

Slide Stroke

|

mm

|

80

|

120

|

140

|

160

|

180

|

|

Slide Strokes

|

spm

|

Times/min

|

100

|

80

|

70

|

60

|

50

|

|

Variable(optional)

|

Times/min

|

60-100

|

50-80

|

45-70

|

40-60

|

35-50

|

|

Max. Die Shut Height

|

mm

|

250

|

270

|

300

|

320

|

350

|

|

Die Shut Height Adjustment

|

mm

|

50

|

60

|

70

|

80

|

90

|

|

Throat Depth

|

mm

|

210

|

225

|

270

|

310

|

350

|

|

Distance Between Columns

|

mm

|

450

|

515

|

560

|

610

|

670

|

|

Slide Bottom Size

|

b

|

mm

|

250

|

340

|

400

|

460

|

520

|

|

L-R

|

mm

|

360

|

410

|

480

|

540

|

620

|

|

Shank Hole Size

|

d

|

mm

|

40

|

50

|

50

|

50

|

70

|

|

Depth

|

mm

|

65

|

60

|

70

|

65

|

90

|

|

Bolster Size

|

D

|

mm

|

400

|

440

|

520

|

600

|

680

|

|

L-R

|

mm

|

720

|

825

|

930

|

950

|

1100

|

|

Thickness

|

mm

|

80

|

110

|

130

|

140

|

155

|

|

Bed Opening Hole Diameter

|

mm

|

150

|

150

|

150

|

180

|

200

|

|

Overall Dimensions

|

A

|

mm

|

1496

|

1585

|

1540

|

1765

|

2040

|

|

L-R

|

mm

|

945

|

1075

|

1200

|

1200

|

1320

|

|

Height

|

mm

|

2120

|

2391

|

2570

|

2725

|

3035

|

|

Motor Power

|

KW

|

3

|

5.5

|

5.5

|

7.5

|

11

|

|

Weight(approximate)

|

kg

|

2450

|

3550

|

5150

|

6450

|

9550

|

|

ITEM

|

UNIT

|

J21s-160

|

J21s-200

|

J21s-250

|

J21s-315

|

J21s-400

|

|

Nominal Capacity

|

KN

|

1600

|

2000

|

2500

|

3150

|

4000

|

|

Slide Stroke

|

mm

|

200

|

220

|

220

|

220

|

250

|

|

Slide Strokes

|

spm

|

Times/min

|

45

|

45

|

30

|

30

|

30

|

|

Variable(optional)

|

Times/min

|

30-45

|

25-45

|

20-30

|

20-30

|

20-30

|

|

Max. Die Shut Height

|

mm

|

400

|

450

|

500

|

500

|

550

|

|

Die Shut Height Adjustment

|

mm

|

100

|

110

|

120

|

120

|

120

|

|

Throat Depth

|

mm

|

400

|

430

|

450

|

450

|

490

|

|

Distance Between Columns

|

mm

|

736

|

910

|

980

|

980

|

1050

|

|

Slide Bottom Size

|

b

|

mm

|

580

|

650

|

700

|

700

|

750

|

|

L-R

|

mm

|

700

|

880

|

950

|

950

|

1020

|

|

Shank Hole Size

|

d

|

mm

|

70

|

70

|

70

|

70

|

70

|

|

Depth

|

mm

|

100

|

100

|

130

|

130

|

130

|

|

Bolster Size

|

D

|

mm

|

760

|

840

|

880

|

880

|

950

|

|

L-R

|

mm

|

1175

|

1390

|

1500

|

1540

|

1700

|

|

Thickness

|

mm

|

165

|

180

|

190

|

190

|

210

|

|

Bed Opening Hole Diameter

|

mm

|

220

|

250

|

270

|

270

|

290

|

|

Overall Dimensions

|

A

|

mm

|

2305

|

2600

|

2660

|

2720

|

2850

|

|

L-R

|

mm

|

1420

|

1540

|

1640

|

1680

|

1750

|

|

Height

|

mm

|

3215

|

3800

|

3865

|

3865

|

4150

|

|

Motor Power

|

KW

|

15

|

18.5

|

22

|

30

|

37

|

5. Accessory List:

|

No

|

Accessory

|

Model / Manufacturer

|

Configuration

|

|

1

|

Main Motor

|

China-made High Performance Motor

|

Standard

|

|

2

|

Electrics

|

Schneider- France

|

|

3

|

Safety Fence

|

Left and Right Safety Fence

|

|

4

|

Lubrication System

|

Manual Lubricating Cap

|

|

5

|

Pedal Switch

|

High Quality Pedal Switch-China

|

Optional

|

|

6

|

Photoelectric protection

|

LNTECH- Shandong

|

|

7

|

Main Motor

|

Siemens-Germany

|

|

8

|

Lubrication System

|

Auto lubrication-China

|

|

9

|

Safety standards

|

■CE □CSA ■NR-12 □OSHA

|

|

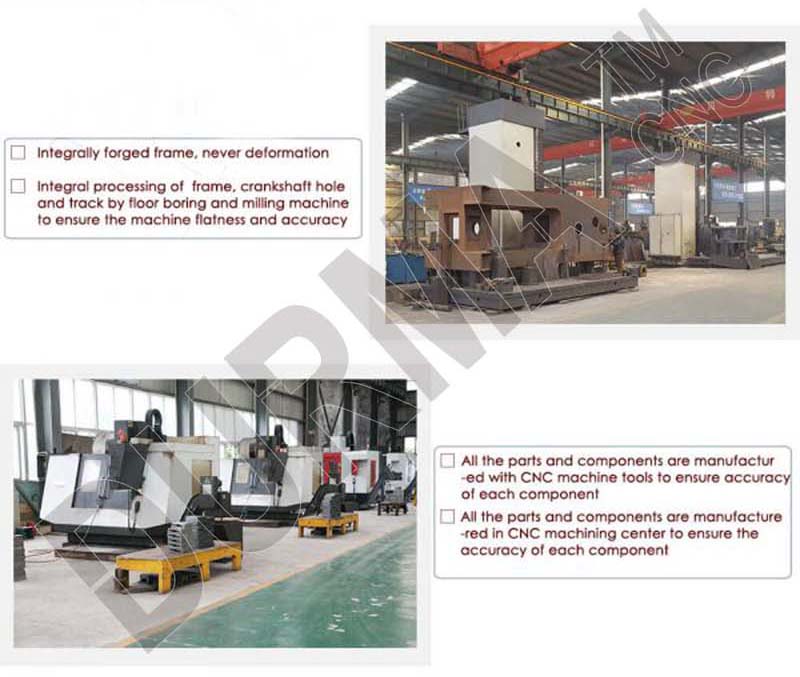

Fabrication Equipment: