Product Item: Y32 Series Four Column Hydraulic Press Machine

Functions

Y32 Series Hydraulic Press Machine Used in Processing Metal Products with a wide range of versatility, suitable for a variety of metal tensile, bending, flanging, cold extrusion, blanking process. Also applies to the correction, press-fit, powder products, abrasive products, grinding wheel, bakelite, resin thermosetting products forming and press-formed in the insulating material of the plastic products.

Technical Performance

1.Four Column Hydraulic Press has Low energy consumption, high speed, low noise, high efficiency;

2. Slider divide speed into two segments to contorl: empty loading fast, slowly close mold, stretch;

3. Activity crossbeam has safety limiter in both up and down directions;

4. Equipped with photoelectric protection device, could guarantee the safety of the operation;

5. With the function of automatic and manual, it's convertible;

6. Two operation model, viz. pressure regulation and stroke regulation which can beselected through operational panel, and has the character of pressure-keeping and time-delaying.

Application

1. Auto parts: automobile body covering parts, braking, fuel tanks, chassis, axle case, bumper;

2. Household appliance: washing machine, TV, refrigerator, air conditioning, rice cooker and other parts;

3. Kitchenware: sink, tea set and Other kinds of containers.

Technical Parameters:

|

Type

|

Unit

|

40T

|

63T

|

100T

|

160T

|

200T

|

250T

|

315T

|

|

Nominal Force

|

KN

|

400

|

630

|

1000

|

1600

|

2000

|

2500

|

3150

|

|

Max. working Pressure

|

Mpa

|

22.6

|

24.7

|

26.3

|

25

|

25

|

25

|

25

|

|

Max. opening Height

|

mm

|

600

|

700

|

800

|

900

|

1000

|

1150

|

1200

|

|

Slider Stroke

|

mm

|

400

|

500

|

550

|

600

|

700

|

750

|

800

|

|

Ejector Force

|

KN

|

63

|

100

|

200

|

250

|

400

|

400

|

630

|

|

Ejector Stroke

|

mm

|

100

|

120

|

160

|

160

|

200

|

200

|

250

|

|

Slider Speed

|

Idle

|

mm/s

|

50

|

80

|

>100

|

>120

|

>120

|

>150

|

>150

|

|

Working

|

mm/s

|

10

|

10

|

8

|

8

|

10

|

10

|

10

|

|

Return

|

mm/s

|

65

|

70

|

85

|

100

|

100

|

100

|

100

|

|

Worktable Size

|

L-R

|

mm

|

400

|

580

|

710

|

800

|

900

|

1120

|

1260

|

|

F-B

|

mm

|

400

|

500

|

580

|

600

|

900

|

900

|

1000

|

|

Blanking Hole Diameter

|

mm

|

Φ100

|

Φ100

|

Φ120

|

Φ120

|

Φ120

|

Φ120

|

Φ120

|

|

Motor Power

|

KW

|

5.5

|

5.5

|

7.5

|

11

|

18.5

|

18.5

|

22

|

|

Overall Size

|

L-R

|

mm

|

1400

|

1600

|

1800

|

2460

|

2800

|

3200

|

3400

|

|

F-B

|

mm

|

1000

|

1000

|

1200

|

1200

|

1200

|

1400

|

1400

|

|

Height

|

mm

|

2300

|

2650

|

2900

|

3200

|

3700

|

3900

|

4150

|

|

Gross Weight

|

KG

|

2000

|

2800

|

4200

|

5500

|

6500

|

7800

|

1200

|

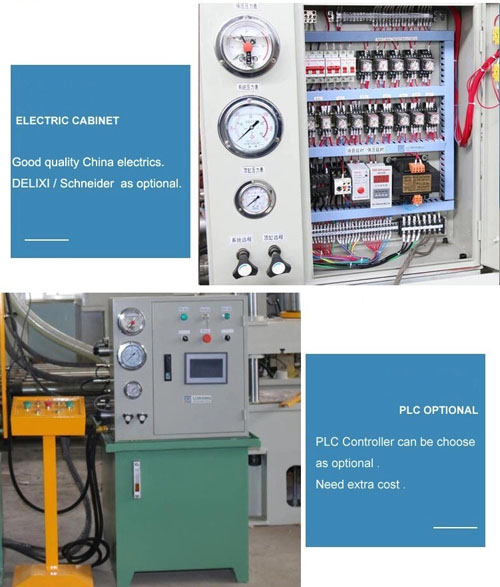

Standard/Optional Accessory List:

|

No

|

Name

|

Model / Manufacturer

|

Configuration

|

|

1

|

Controller

|

OMRON PLC ( Touch Screen )

|

Standard

|

|

2

|

Main Motor

|

Siemens – Germany

|

|

3

|

Main Electric Elements

|

Schneider – France

|

|

4

|

Hydraulic System

|

Bosch Rexroth - Germany

|

|

5

|

Sealing Ring

|

NOK – Japan

|

|

6

|

Oil Pump

|

SAEMP – Shanghai

|

|

7

|

Photoelectric Protection

|

LNTECH – Shandong

|

Optional

|

|

8

|

Damping Device

|

DURMACNC

|

|

9

|

Fast Clamp

|

DURMACNC

|

|

10

|

Air-cooling device

|

China

|

|

11

|

Safety Standards

|

CE CSA NR-12 OSHA

|