features

●The measurement is not affected by fluid density, viscosity, temperature, pressure, and conductivity.

●Open flow parts in measuring pipe, no pressure loss, lower requirements of straight pipe section, unique adaptability to slurry measurement.

●The flow meter has no mechanical movable parts, and the converter is of optimized design, compact structure and easy to install. The converter and sensor are interchangeable, and the measurement range can be changed freely (0.5m/s-10m/s).

●Reasonable selection of electrode and lining material, that is, good corrosion resistance and wear resistance.

●Full digital processing, strong anti-interference ability, reliable measurement, high precision, wide flow measurement range.

●Ultra low EMI switching power supply, suitable for power supply voltage range, EMI resistance is good.

●The 16-bit embedded microprocessor is adopted, which has the advantages of fast operation speed, high precision, low frequency rectangular wave excitation, and programmable excitation frequency setting, so as to improve the stability of flow measurement and low power consumption.

●There are no moving parts or open flow parts in the pipe, and there is almost no additional pressure loss in the measurement.

●The measuring range can be modified online according to the actual needs of users.

High definition backlight LCD display, full Chinese menu operation, easy to use, easy to operate, easy to learn and easy to understand.

●With RS485,R5232, Hart and Modbus profibus-dp and other digital communication signal output (optional).

●It has the function of self-examination and self-diagnosis.

●The function of hourly total volume recording, which records the total flow volume in hours, is applicable to time-sharing measurement system (optional).

●Inside, there are three calculators which can display the forward cumulant, reverse cumulant and difference product respectively. Inside, there is a power off clock which can record the power off time for 16 times (optional).

●Infrared handheld operator, 115KHz communication rate, remote non-contact operation converter all functions (optional).

●Insert type electromagnetic flowmeter, easy to install, can not break the flow, the site can be with pressure hole, has the absolute advantage of installation and price advantage.

●Insert type electromagnetic flowmeter, the flow detection is only related to the insertion depth, so the flowmeter has wide versatility and strong interchangeability.One model can be used for fluid measurement requirements of pipes of various specifications.

Meter Selection

Product selection Table 1

|

Model

|

Description

|

|

LDB-

|

□

|

□

|

□

|

□

|

□

|

□

|

□

|

□

|

□

|

Full pipe type electromagnetic flowmeter

|

|

LDC-

|

|

|

|

|

|

|

|

|

|

Plug-in type electromagnetic flowmeter

|

|

Nominal diameter

|

|

|

|

|

|

|

|

|

|

10-2200mm

|

|

Assembly

|

S

|

Integrated type

|

|

L

|

Separate type

|

|

Electrode material

|

M

|

316L Stainless steel

|

|

T

|

Ti (titanium)

|

|

D

|

Ta(tantalum)

|

|

Hb

|

Hastelloy-B

|

|

Hc

|

Hastelloy-C

|

|

P

|

Pt platinum

|

|

w

|

Tungsten carbide

|

|

Output mode

|

0

|

No output

|

|

1

|

4-20mA/1-5KHz

|

|

2

|

4-20mA

|

|

Lining material

|

X

|

Rubber

|

|

F

|

PTFE

|

|

P

|

Polyethylene

|

|

J

|

Polyurethane rubber

|

|

Local display

|

0

|

No local display

|

|

1

|

Local display

|

|

Communication mode

|

0

|

No communication

|

|

1

|

RS485

|

|

2

|

RS232

|

|

3

|

Modbus

|

|

4

|

Hart

|

|

Grounding ring

|

0

|

Without grounding ring

|

|

1

|

With grounding ring

|

|

2

|

Ground electrode

|

|

Upper limit flow

|

(n)

|

Upper limit flow (range) m3/h

|

Example: a local display electromagnetic flowmeter was selected to measure sewage. The user's pipeline was DN50, which required rubber material village, stainless steel electrode, 4-20ma output, no communication, and the online flow was 30m3/h.The model will be LDB-50s - m1x100-30.

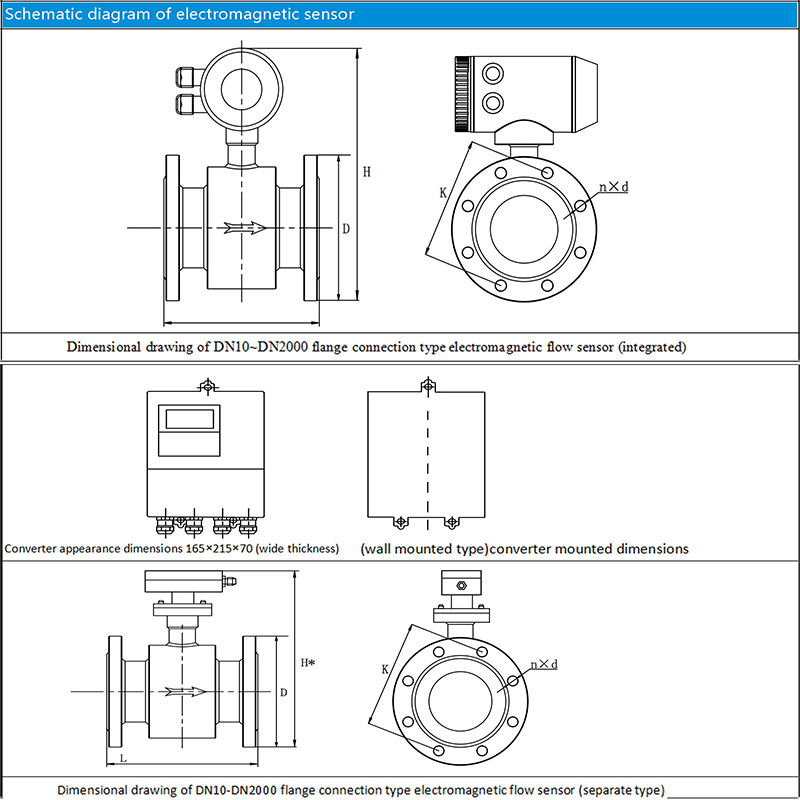

Appearance and mounting dimensions of electromagnetic flowmeter

1、Full tube electromagnetic sensor size parameters

Ⅰ Sensor dimensions

Ⅱ Sensor mounting dimensions Table 2

|

Nominal diameter

(mm)

|

L(mm)

|

D(mm)

|

K(mm)

|

H(mm)

|

H*(mm)

|

n×d(mm)

|

Pressure rating

|

Special pressure rating

|

|

10

|

200

|

90

|

60

|

310

|

220

|

4×Ф14

|

4MPa

|

Below 16MPa

|

|

15

|

200

|

95

|

65

|

310

|

220

|

4×Ф14

|

|

20

|

200

|

105

|

75

|

315

|

225

|

4×Ф14

|

|

25

|

200

|

115

|

85

|

325

|

235

|

4×Ф14

|

|

32

|

200

|

140

|

100

|

325

|

235

|

4×Ф18

|

1.6MPa

|

|

40

|

200

|

150

|

110

|

340

|

250

|

4×Ф18

|

|

50

|

200

|

165

|

125

|

355

|

265

|

4×Ф18

|

|

65

|

200

|

185

|

145

|

375

|

285

|

4×Ф18

|

|

80

|

250

|

200

|

160

|

385

|

295

|

8×Ф18

|

|

100

|

250

|

220

|

180

|

415

|

325

|

8×Ф18

|

|

125

|

250

|

250

|

210

|

445

|

355

|

8×Ф18

|

|

150

|

300

|

285

|

240

|

475

|

385

|

8×Ф18

|

|

200

|

350

|

340

|

295

|

505

|

415

|

12×Ф22

|

2.5MPa

|

|

250

|

450

|

395

|

350

|

590

|

500

|

12×Ф22

|

1.0MPa

|

|

300

|

500

|

445

|

400

|

645

|

555

|

12×Ф22

|

|

350

|

500

|

505

|

460

|

695

|

605

|

16×Ф22

|

|

400

|

500

|

565

|

515

|

745

|

655

|

16×Ф26

|

|

450

|

550

|

615

|

565

|

825

|

735

|

20×Ф26

|

|

500

|

550

|

670

|

620

|

878

|

788

|

20×Ф26

|

|

600

|

600

|

780

|

725

|

988

|

898

|

20×Ф30

|

|

700

|

700

|

860

|

810

|

1095

|

1005

|

24×Ф30

|

0.6MPa

|

1.0MPa

|

|

800

|

800

|

975

|

920

|

1208

|

1118

|

24×Ф34

|

|

900

|

900

|

1075

|

1020

|

1310

|

1220

|

28×Ф34

|

|

1000

|

1000

|

1175

|

1120

|

1413

|

1323

|

28×Ф36

|

|

1200

|

1200

|

1450

|

1340

|

1525

|

1435

|

32×Ф33

|

|

1400

|

1400

|

1630

|

1560

|

1735

|

1645

|

36×Ф36

|

|

1600

|

1600

|

1830

|

1760

|

1965

|

1875

|

40×Ф36

|

|

1800

|

1800

|

2045

|

1970

|

2155

|

2065

|

44×Ф39

|

|

2000

|

2000

|

2265

|

2180

|

2365

|

2275

|

48×Ф42

|

Electromagnetic Flowmeter Installation Precautions

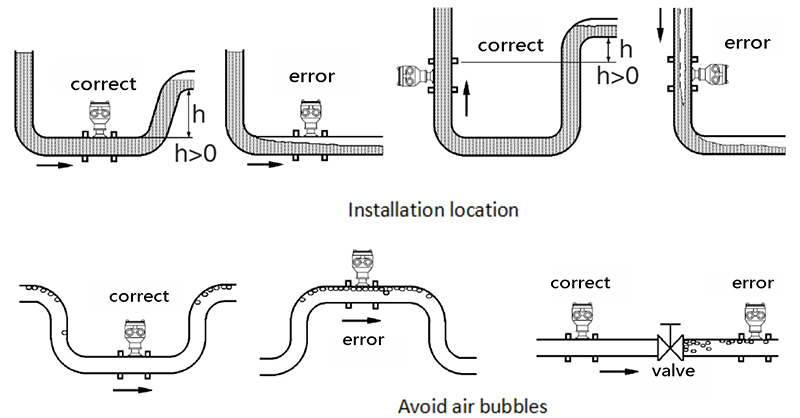

1. Installation location

The pipe must be completely filled with liquid, which is critical, otherwise the flow display will be affected and measurement errors will occur. The pipe structure must be designed to ensure that the flow pipe is always filled with fluid.When the fluid is diverted or combined with solid particulate deposits,vertical installation is recommended, but for vertical installations,it need to follow the fluid direction from bottom to top to ensure that the pipe is full of fluid.

Avoid air bubbles. If air bubbles enter the flow pipe, the flow display will be affected ,and measurement errors will occur. When the fluid contains air bubbles, the pipe must be designed to prevent air bubbles from accumulating in the flow pipe. If there is a valve near the flow measuring pipe, place the pipe upstream of the valve as much as possible to avoid pressure reduction and bubble generation.

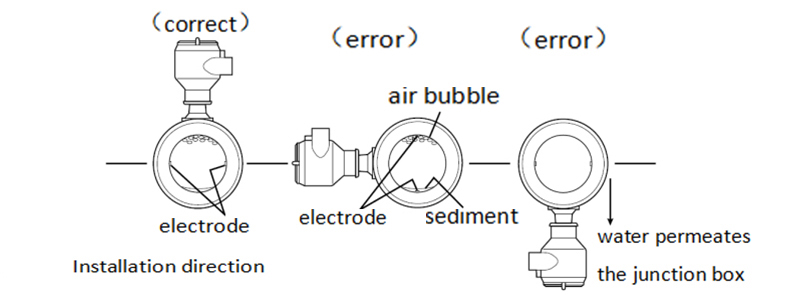

2. Installation direction

If the electrode is perpendicular to the ground, bubbles gathered at the top or deposits deposited at the bottom can cause measurement errors. Install the separate type flow pipe junction box and the integrated type converter on top of the pipe system to prevent water from entering.

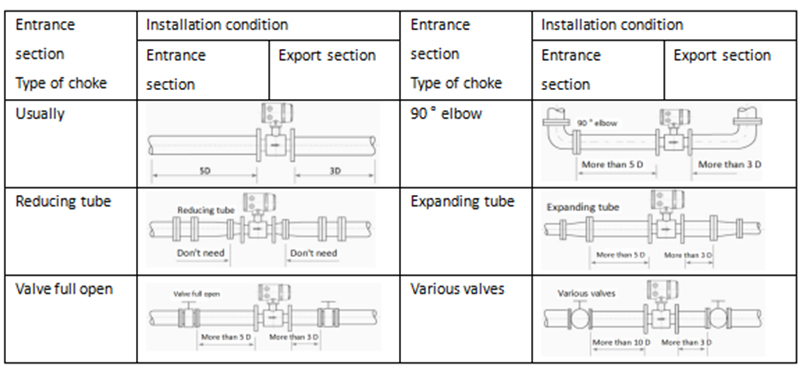

3.Direct pipe section requirements

Do not install anything near the flow pipe that may interfere with the magnetic field, the induced signal voltage, and the flow field distribution of flow pipe. In general,it is necessary to ensure a 5D of straight pipe section for the upstream and a 3D of straight pipe section for the downstream. If there are interference flow parts such as elbows and valves, the length of the straight pipe section required should be larger. It is highly recommended to install the valve at the downstream end to avoid flow fluctuations in the flow pipe and to avoid counting from the empty pipe status.

Maintain stable fluid conductivity

Avoid installing the flowmeter in a position where fluid conductivity is not uniform.If chemicals are injected near the upstream end of the electromagnetic flowmeter, flow visualization may be affected.To avoid this situation, it is recommended to change the chemical injection to the downstream end of the flowmeter.If it is necessary to inject from the upstream end, use a straight pipe section long enough (about 50D) to ensure that the fluid is thoroughly mixed with the chemicals.