Features

■ Direct measurement of mass flow of gas without pressure and temperature compensation;

■High repeatability, high reliability, high stability and high precision;

■Range range width: up to 1000:1 or more;

■Explosion-proof, anti-corrosion design, suitable for harsh conditions, corrosive occasions;

■High sensitivity, especially suitable for flow measurement of large diameter and low flow rate;

■Eextremely small pressure loss and almost negligible;

■Diverse structure, flexible installation, convenient loading and unloading, easy to use, basically maintenance;

■ LCD display, clear and intuitive, showing both instantaneous flow and cumulative flow, so that you can see more clearly and more directly;

Product Classification

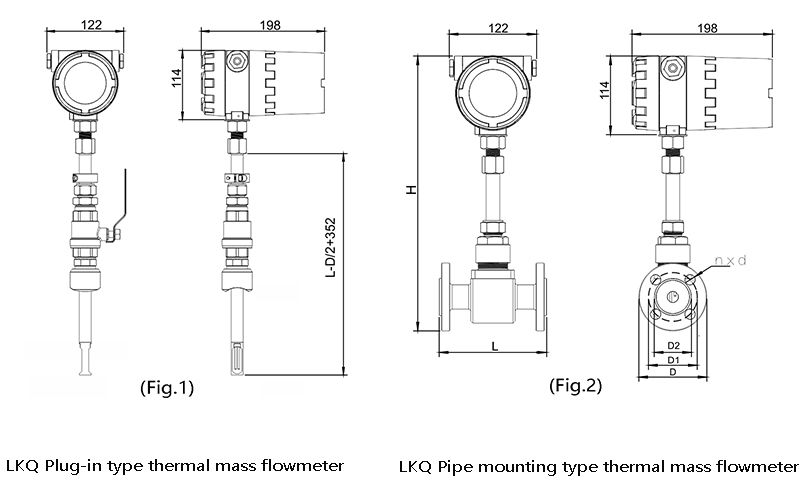

LKQ-A1 plug-in type

Applicable to gas mass flow measurement with pipe diameter greater than DN80. The meter has features such as high precision, good repeatability, high reliability, wide range ratio, fast response, simple and convenient installation, basic free of maintenance, almost no pressure loss, pipe diameter has a very small influence on the price. It has become more and more widely used in the field of gas measurement. Especially after the design with the ball valve installation, it breaks the history that the gas must be shut down when installing the flowmeter on site, which greatly facilitates the use.

LKQ-A2 pipe mounting type

Applicable to gas mass flow measurement with pipe diameter less than DN65. It uses a more beautiful design, with double circlip, ten-layer V-type PTFE gasket, and flange with concave and convex surface, so that the meter will not leak under high pressure, which is more convenient for use, disassembly and maintenance.

LKQ-A2F3 anti-corrosion type

He anti-corrosion type thermal gas mass flowmeter has all the features of the conventional thermal mass flowmeter and the sheath of the sensor is made of special metal material tantalum with good acid corrosion resistance, and in the concentration of 28~29% hydrochloric acid ( at this concentration, hydrochloric acid is the most corrosive to metals.) the wall thickness will be corroded by 4u every year. If the wall thickness of the sheath is to be completely corroded, it takes more than ten years,moreover, the corrosive properties of chlorine, phosgene and other gases actually used are not as corrosive as the concentration of 28, 29% hydrochloric acid solution, and the PBF probe and the pipe to be tested are reliably sealed.

Meter modeling Table 1

|

LKQ

|

-□

|

□

|

□

|

□

|

□

|

□

|

□

|

Code description

|

|

Installation form

|

|

|

|

A1

|

|

|

|

Plug-in type

|

|

|

|

|

A2

|

|

|

|

Pipe mounting type

|

|

Power supply

|

|

|

|

B1

|

|

|

|

220VAC

|

|

|

|

|

B2

|

|

|

|

24VDC

|

|

Output signal

|

|

|

|

C1

|

|

|

|

4~20mA

|

|

|

|

|

C2

|

|

|

|

RS485

|

|

|

|

|

C3

|

|

|

|

HART

|

|

Whether the meter has a display

|

|

|

|

D1

|

|

|

|

No display at the meter head

|

|

|

|

|

D2

|

|

|

|

Header instantaneous flow display

|

|

|

|

|

D3

|

|

|

|

Header instantaneous and cumulative flow display

|

|

Whether it has intelligent flow totalizer

|

|

|

|

E1

|

|

|

|

No flow totalizer

|

|

|

|

|

E2

|

|

|

|

With intelligent flow totalizer

|

|

Special requirements

|

|

|

|

F1

|

|

|

|

No special requirements

|

|

|

|

|

F2

|

|

|

|

Flameproof

|

|

|

|

|

F3

|

|

|

|

Corrosion resistant (sensor is tantalum material)

|

|

|

|

|

F4

|

|

|

|

High temperature type (150-250℃)

|

|

Flowmeter and pipe seal connection

|

|

|

|

L1

|

|

|

|

Continuous flow assembly and disassembly device (ball valve) <0.8Mpa

|

|

|

|

|

L2

|

|

|

|

Continuous flow assembly and disassembly device (ball valve) + high pressure seal assembly <2.0Mpa

|

|

|

|

|

L3

|

|

|

|

Simple threaded assembly <0.8Mpa

|

|

|

|

|

L4

|

|

|

|

Threaded component + high pressure seal assembly <2.0Mpa

|

|

|

|

|

W1

|

|

|

|

Flange type components >2.0Mpa

|

|

|

|

|

W2

|

|

|

|

Flange type heat dissipation component (high temperature type)

|

|

|

|

|

W3

|

|

|

|

The sampling pipe is flanged to the pipe under test on site

|

|

|

|

|

W4

|

|

|

|

The sampling pipe is threaded to the pipe under test on site

|

|

Practical pipe diameter

|

|

|

|

|

|

|

-

|

Based on the actual inner diameter of the pipe at the user site (for example, the inner diameter of the pipe is 300mm, it is indicated by the number 300)

|

Installation Dimension and Requirements

Installation dimension(see Table 2)

Table 2

|

Nominal diameter

|

Overall dimension

|

Flange dimension

|

|

DN(mm)

|

L(mm)

|

H(mm)

|

D(mm)

|

D1(mm)

|

D2(mm)

|

|

25

|

125

|

320

|

115

|

85

|

65

|

|

40

|

135

|

345

|

150

|

110

|

84

|

|

50

|

140

|

358

|

165

|

125

|

99

|

|

80

|

194

|

390

|

200

|

160

|

132

|

|

100

|

230

|

410

|

220

|

180

|

156

|

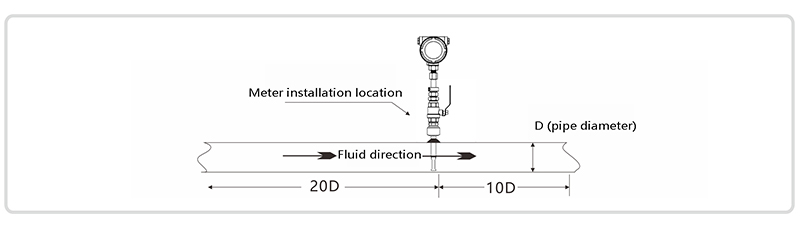

Installation requirements

a. The length of the straight pipe section of the pipe to be tested at the installation of the flowmeter shall meet: upstream 20D distance, downstream 10D distance (D is the inner diameter of the pipe). By using our rectifying flowmeter (pipe diameter ≤ DN100), the length requirements of the front and rear straight pipe sections can be greatly reduced.

b. The flow regulating valve should be installed as least 10D far from downstream of the flowmeter . If it must be installed at the front end, it should be far away from the measuring point.