Flexing tests are sometimes required to be carried out at low temperatures below 0°C.

This low temperature version of the Schildknecht Method Flexing Machine is built into a low temperature cabinet. It is used for the flex testing of rubber or plastic-coated fabric to assess the effect of flexing under low temperature conditions. After repeatedly flexing and bending, check its degree of damage, crack and deterioration. It has 6 stations for small samples but can also accommodate larger samples by adjusting the mechanism.

Test Principle

A rectangular strip of coated fabric is mounted around two opposing cylinders so that the test piece takes a cylindrical form. One of the cylinders reciprocates along its axis, causing the coated-fabric cylinder to be alternately compressed and relaxed, thus inducing folds in the test piece. This folding of the coated-fabric cylinder if continued for either a pre-set number of cycles or until damage to the test piece is apparent.

Standards

ISO 7854 , BS 3424, GB/T 12586

Features

1.Electrical control and drive systems outside the freezer area where moisture cannot impair electrical safety, which ensures maximum operator safety.

2.The control system consists of a digital temperature controller which can be set to achieve the required temperature from ambient down to -20°C, as well as a counter indicating the flexing number carried out.

3.Machine stop automatically when test completed by counter.

4.Been upgraded with a new model, compact design, optimized transmission structure and test structure;

5.Adopts advanced numerical control laser laser cutting, numerical control molding process production, the surface scenic spot spraying baking paint processing, the paint surface is firm and durable;

Configuration Status

1.Equipped with emergency stop button, in case of emergency, the operation can be stopped quickly to protect the safety of personnel;

2.Clamping mode of clamped sample, linkage of six stations, greatly improve the test efficiency;

3.Eccentric reciprocating transmission mechanism, simple structure, stable travel, stable and reliable operation, smooth operation, quiet;

4.The left and right sides are symmetrical with two linear sliding rails carrying reciprocating structure, excellent guidance and high precision, running more smoothly and quietly;

5.LED highlighting digital display instrument, digital display bright and clear, simple setting;

6.The circulating ventilation system can cool down the operation temperature of the instrument for a long time and ensure the stable internal operation environment of the instrument;

7.Universal jump screen rubber sole provides horizontal and stable support for the instrument.

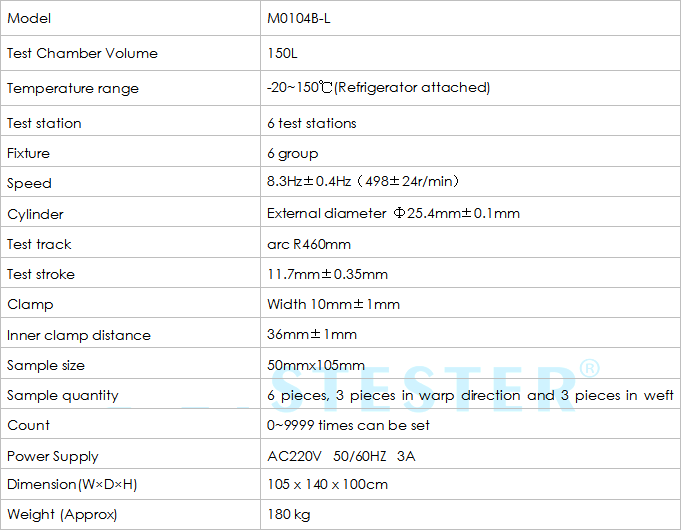

Key Specification

Applications