Features

■The accuracy is high, the accuracy of measuring liquid is usually 11.0%, and the accuracy of measuring gas is ±1.5%;

■The measurement range is wide, and in the range of Reynolds number is 2×104~7×106, it can reach 1:20;

■Low pressure loss(about 1 /4-1 /2 of the orifice flowmeter), which belongs to the energy-saving flow instrument;

■The installation method is changeful. It can be installed horizontally, vertically and at different angles according to different process pipelines;

■It adopts ultra-low-power single-chip microcomputer technology. For one 3V10Ah battery, can be used for more than 5 years;

■Adopts EPROM to conduct power fail safeguard to the accumulative flow, and the effective protection time is more than 10 years;

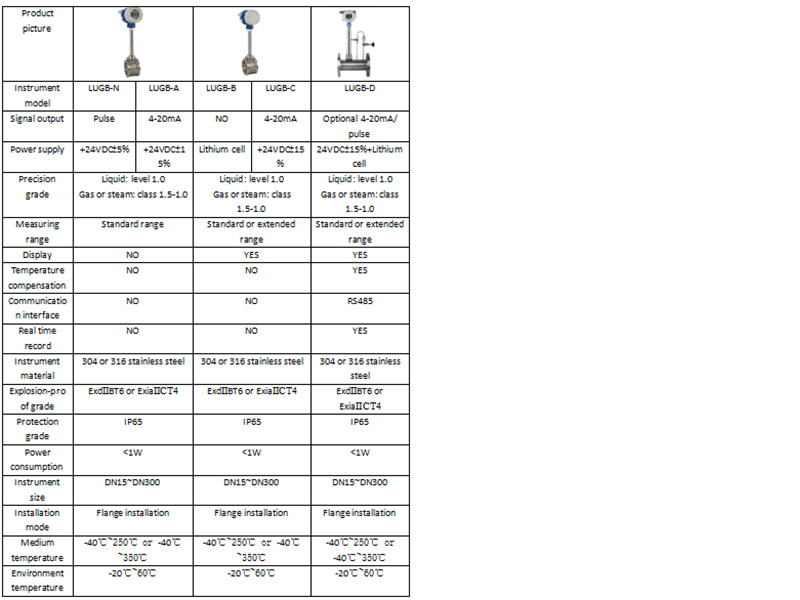

Product Classification Table 1

Product selection Table 2

|

Model

|

Interpretation

|

|

LUGB

|

□

|

□

|

□

|

□

|

□

|

□

|

Full tube vortex flowmeter

|

|

LUCB

|

□

|

□

|

□

|

□

|

□

|

□

|

Plug-in vortex flowmeter

|

|

Connection mode

|

1

|

|

|

|

|

|

Flange connection(for full tube vortex flowmeter)

|

|

2

|

Flange clamping(for full tube vortex flowmeter)

|

|

3

|

Simple plug-in (suitable for plug-in vortex flowmeter)

|

|

4

|

Ball valve plug-in (suitable for plug-in vortex Flowmeter)

|

|

Measured medium

|

1

|

liquid

|

|

2

|

General gas

|

|

3

|

Compressed air

|

|

4

|

Steam

|

|

Nominal diameter

|

00

|

15mm

|

|

01

|

20mm

|

|

02

|

25mm

|

|

03

|

32mm

|

|

04

|

40mm

|

|

05

|

50mm

|

|

06

|

65mm

|

|

08

|

80mm

|

|

10

|

100mm

|

|

12

|

125mm

|

|

15

|

150mm

|

|

20

|

200mm

|

|

25

|

250mm

|

|

30

|

300mm

|

|

|

Plug - in direct indication of nominal size

|

|

Compensation

|

N

|

Uncompensated

|

|

T

|

Temperature compensation(Suitable for steam measurement)

|

|

P

|

Pressure compensation(Suitable for compressed air measurement)

|

|

F

|

Temperature and pressure compensation

|

|

Converter type

|

N

|

Sensor type: +12V or +24V power supply, output three-wire pulse signal

|

|

A

|

Transmitter type: +24VDC power supply, output two-wire 4 ~ 20mA

|

|

B

|

Intelligent type: lithium battery power, no signal output field display

|

|

C

|

Intelligent type: +24V power supply, field display and output 2-wire system 4~20mA

|

|

C1

|

Intelligent type: +24V power supply, field display and RS485 communication protocol

|

|

C2

|

Intelligent type: +24V power supply, field display and HART communication protocol

|

|

Explosion-proof grade

|

N

|

Standard type, not explosion-proof

|

|

E

|

Flameproof type,ExdⅡBT6

|

Example: a flange-clamped standard vortex street flowmeter is selected to measure steam. The pipe is DN50, and the field needs to display the flow rate and transmit the current signal. The product model should be:LUGB-2405NCN.

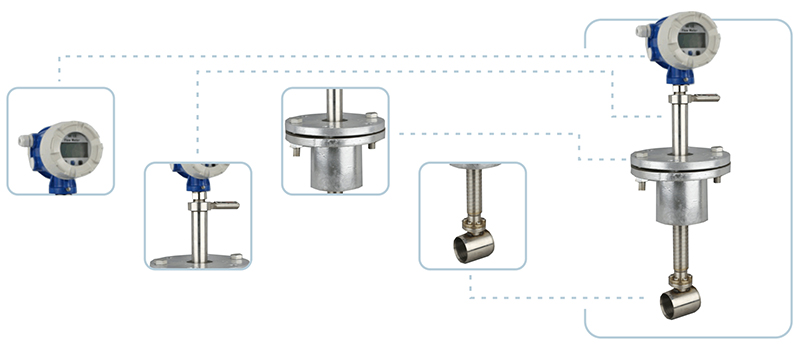

Installation and dimensions of plug - in vortex flowmeter

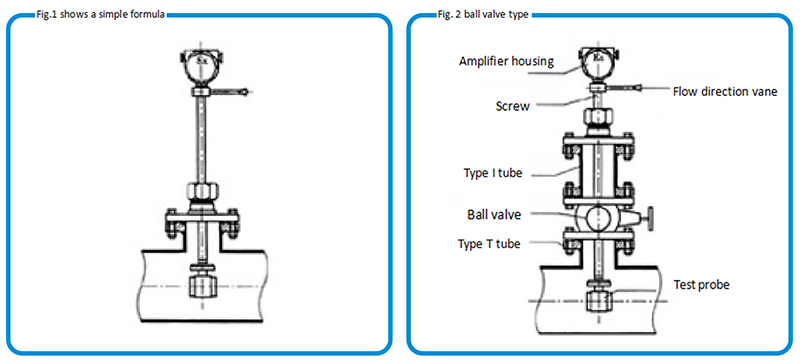

1. Structure form

2. Simple installation method of flow meter

●To meet the requirements of the straight pipe flowmeter installation point open a Φ 100 round.

●Use Φ109 x 4.5mm base section and open good mouth round the welding line, base after welding visual inspection may not have obvious askew.

●Insert the velocity probe into the pipe, adjust the insertion depth so that the center of the probe and the central axis of the pipe want to be consistent, the Angle between the center line of the probe and the central axis of the pipe should not be more than 5 degrees, and then adjust the flow direction mark to make it the same as the flow direction of the fluid.

●Connect flange or ball valve to welded base and bolt.

3.Ball valve type flowmeter (with globe valve) installation and removal method

Technical requirements

●Non-injection size and materials are determined by the user according to the pressure strength and anti-corrosion requirements.

●The "mounting base" shall be in a correct position on the pipe without obvious deviation.

●Non-steel pipes may be clamped to fix the "mounting base" provided that the gap size shown in the drawing is 85mm so that the bolt M16 × 65 is bolted from the gap when installing the ball valve.

●Standard for flange connection dimensions: GB4216.4-84