Machining garolite green color g10 fr4 epoxy glass laminate sheet

FR-4 (or FR4) is a grade specified for glass fiber reinforced epoxy laminates, tubes, rods, and printed circuit boards (PCBS).FR-4 is a composite material consisting of a woven fiberglass cloth and an epoxy resin binder that is flame retardant (self-extinguishing).

The NEMA g-10 grade material is a continuous filament woven fiberglass board bonded with epoxy resin.The material maintains excellent mechanical, electrical and physical properties at high temperaturesThe temperature is 130°C.NEMA g-10 is a bromin-free, non-flame retardant grade glass epoxy laminate

G10/FR4 Machining:

JY Machinery is your reliable, precision processing source.We are the industry leader in FR4 / G10 machining.We were able to maintain tolerances, create features and produce parts.By using a high-speed spindle with a speed of 30,000 RPM, a tightly controlled work range, and a state-of-the-art workpiece clamping system, JY machinery can process high-pressure lamination parts from the simplest parts to the most complex parts in our precision machines.If you are looking for FR4 / G10 parts for precision machining,

Request a Quote today.

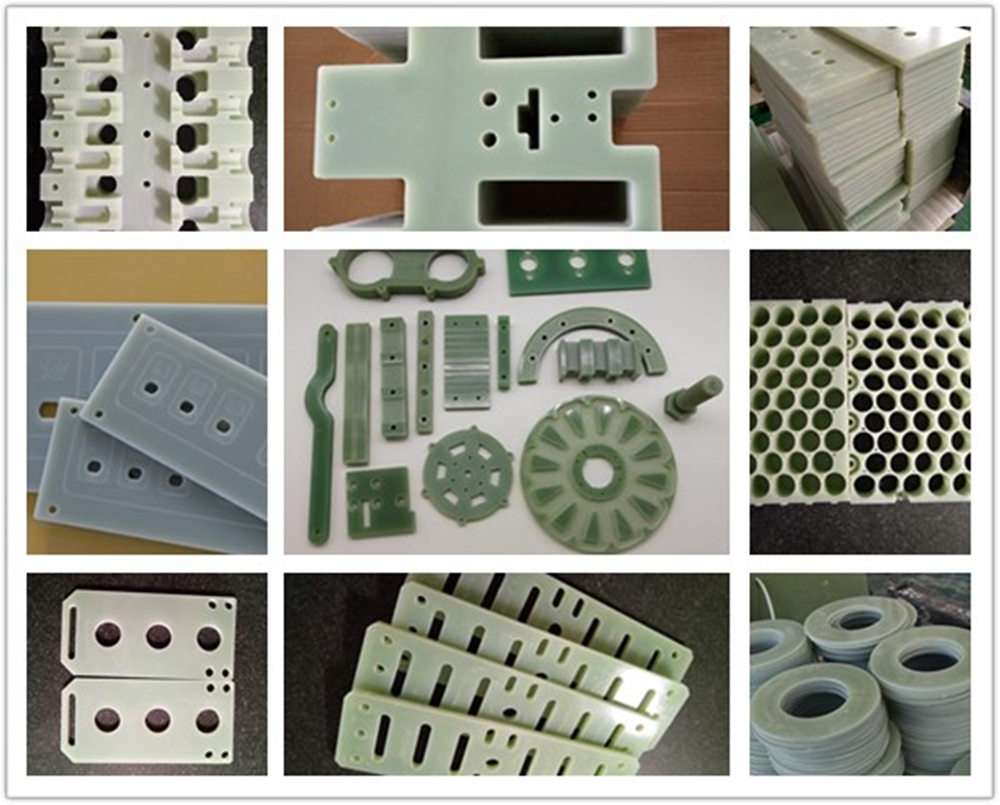

PRODUCT SHOW:

Product Parameter:

|

EPOXY GLASS CLOTH LAMINATED SHEET TYPE G-10

|

|

No.

|

Test Item

|

Test condition

|

Unit

|

Standard Value

|

Testing Result

|

|

1

|

Density

|

‐‐

|

g/cm3

|

≥1.70

|

1.85

|

|

2

|

Moisture Absorption (0.187”)

|

ASTM D-570

|

%

|

0.15 max

|

0.02

|

|

3

|

Breakdown Voltage Condition A

(0.062”) Condition D-48/50

|

ASTM D-149

|

kV

|

45 min

40 min

|

50

47

|

|

4

|

Permittivity (0.187'') Condition A

Condition D-24/30

Condition D-48/50

|

ASTM D-150

|

‐‐

|

5.20

5.40

5.80

|

4.60

4.60

4.70

|

|

5

|

IZOD Impact Strength (0.187”) Length-Wise

Cross-Wise

|

ASTM D-229

|

ft-lb/in

Notched

|

7.0 min

5.5 min

|

15

10

|

|

6

|

Flexural Strength (0.187”) Length-Wise

Cross-Wise

|

ASTM D-790

|

ksi (MPa)

|

55 (380) min

45 (311) min

|

80 (552)

70 (483)

|

|

7

|

Flexural Modulus (0.187”) Length-Wise

Cross-Wise

|

ASTM D-790

|

psi

|

‐‐

|

2,700

2,400

|

|

8

|

Tensile Strength (0.125”) Length-Wise

|

ASTM D-638

|

psi

|

‐‐

|

45,000

38,000

|

|

9

|

Compressive Strength

|

ASTM D-695

|

psi

|

‐‐

|

65,000

|

|

10

|

Hardness Rockwell M

|

ASTM D-785

|

‐‐

|

‐‐

|

M110

|

|

11

|

Bonding Strength (0.500”) Condition A

Condition E-48/50

|

ASTM D-229

|

Lb (kg)

|

2,000 min

1,600 min

|

2,300

2,200

|

|

12

|

Shear Strength (punch type, 0.125”)

|

ASTM D-732

|

ksi (MPa)

|

‐‐

|

25 (172)

|

|

13

|

Temperature Index

|

ASTM D-2304

|

℃

|

‐‐

|

130

|

|

14

|

Thermal Conductivity

|

ASTM C-177

|

(BTU-in/ft²-hr-°F)

(x 10-4 cal/cm-sec-°C)

|

‐‐

|

2.0

7.0

|

|

15

|

Coefficient of Linear Thermal Expansion Length-wise

Cross-wise

|

ASTM D-696

|

X 10-5 in./in./°F

|

‐‐

|

0.55

0.66

|

|

16

|

Flammability Rating

|

UL94

|

Class

|

‐‐

|

H-B

|

|

17

|

Dissipation Factor @ 1 MHz Condition A

(0.187”) Condition D-24/30

Condition D-48/50

|

ASTM D-150

|

‐‐

|

0.025

0.035

0.045

|

0.018

0.019

0.020

|

|

18

|

Dielectric Strength (Condition A)

|

ASTM D-149

|

V/mil

|

‐‐

|

800

|

|

19

|

Arc Resistance (0.125”)

|

ASTM D-495

|

Sec

|

‐‐

|

130

|

|

20

|

Comparative Tracking Index (0.125”)

|

ASTM D-3638

|

V

|

‐‐

|

200

|

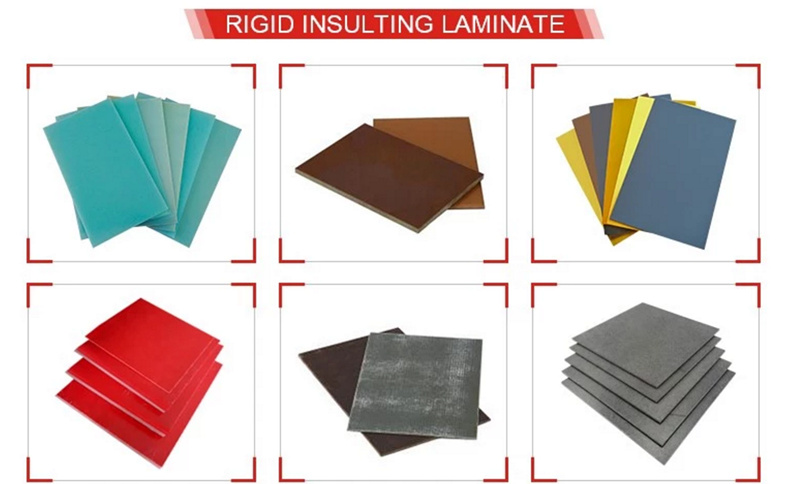

OUR INSULATION PROUCTS RANGE:

•Epoxy Glass Fiber cloth laminated sheet series环氧玻璃布层压板系列

•Phenolic laminated sheet series酚醛层压板系列

•Polyester Laminated sheets series聚酯板材系列

•SMC/BMC/DMC Molded Parts团状模塑料

•Insulation Rods&Tubes绝缘管棒

•Pultruded Profiles拉挤型材

•Engineering Plastics Parts工程塑胶制品

OUR COMPANY:

Composite Insulating Materials, including 3240, FR4, FR5, G10, G11 epoxy fiberglass sheet, GPO-3, SMC Unsaturated polyester sheet, bakelite sheet,

phenolic cloth/paper sheet and various deep processing products. The company has various types of gluding machines, dryers, presses, laser cutters

and sanders. Introducing advanced Korean engraving machins and automatic CNC machines. We carry out deep processing of different non-metallic

materials according to customers’pictures, CAD drawing or samples.

JY Machinery has strong technical strength and adhere to“Technical Innovation as the guide”. After more than 10 years of development, our company

has a full range of insulated products. Sheets & Rods from thin to extra-thick to meet different needs of the customers. With the excellent quality and

service, we are the supplier of the well-known ernterprices like ABB, Siemens, etc and provide technical support and insulation material supply for many

big metro projects, like Doha, Beijing, Hanghzou, Ningbo metros. Our products are widely used in rail transit, power transmission and transformation, new

energy, aerospace, shipbuilding, military, electronics, etc. At present, the products has been exported to many countries and has won high praise of

customers at home and abroad.

We strive to create the most professional manufacturers of insulating materials and non-metal materials processing enterprise. Find the best solution for

your various applications. Welcome to speak with JY MACHINERY for setting up win-win partnership.