Overview

Mineral-Insulated (MI) Cables use inorganic mineral materials (typically MgO) as insulation, featuring exceptional fire resistance, high-temperature endurance, and chemical corrosion resistance. They maintain circuit integrity under extreme conditions and are ideal for life-safety systems and critical power. Constructions include copper-sheathed or stainless-steel-sheathed designs, with options for LSZH outer covering, armouring, and multi-core configurations to suit diverse installations.

Typical voltage ratings: 300/500 V, 450/750 V, 0.6/1 kV, up to 3.6/6 kV for special designs

Conductors: Copper (plain/tinned), nickel-plated copper for high-temperature options

Insulation: High-purity magnesium oxide (MgO) mineral insulation

Sheath: Copper tube (common) or stainless steel (SS304/316) for harsh/corrosive environments

Outer covering: LSZH or LSOH extruded jacket (optional) for mechanical protection/marking

Armouring: Optional tape or wire armour for mechanical impact and burial

Fire performance: Fire-resistant (maintains circuit integrity under flame), low-smoke, halogen-free options

Applications: Fire pumps, emergency lighting, smoke extraction, tunnels, metros, petrochemical plants, data centers, hospitals, high-rise buildings

Standards: IEC 60702-1/-2, BS 6387 (CWZ), BS 8491, EN 50200, GB/T 13033, GB/T 34926, UL 2196 (where applicable)

Key Features

Inorganic insulation with outstanding fire survival; circuit integrity under fire, impact, and water spray

High temperature capability: continuous up to 250°C (higher for special types), short-term up to 950–1000°C

Halogen-free, low smoke, non-aging insulation; excellent corrosion and radiation resistance

Very low capacitance and dielectric loss; stable electrical parameters over service life

Durable metallic sheath with excellent EMC shielding and mechanical strength

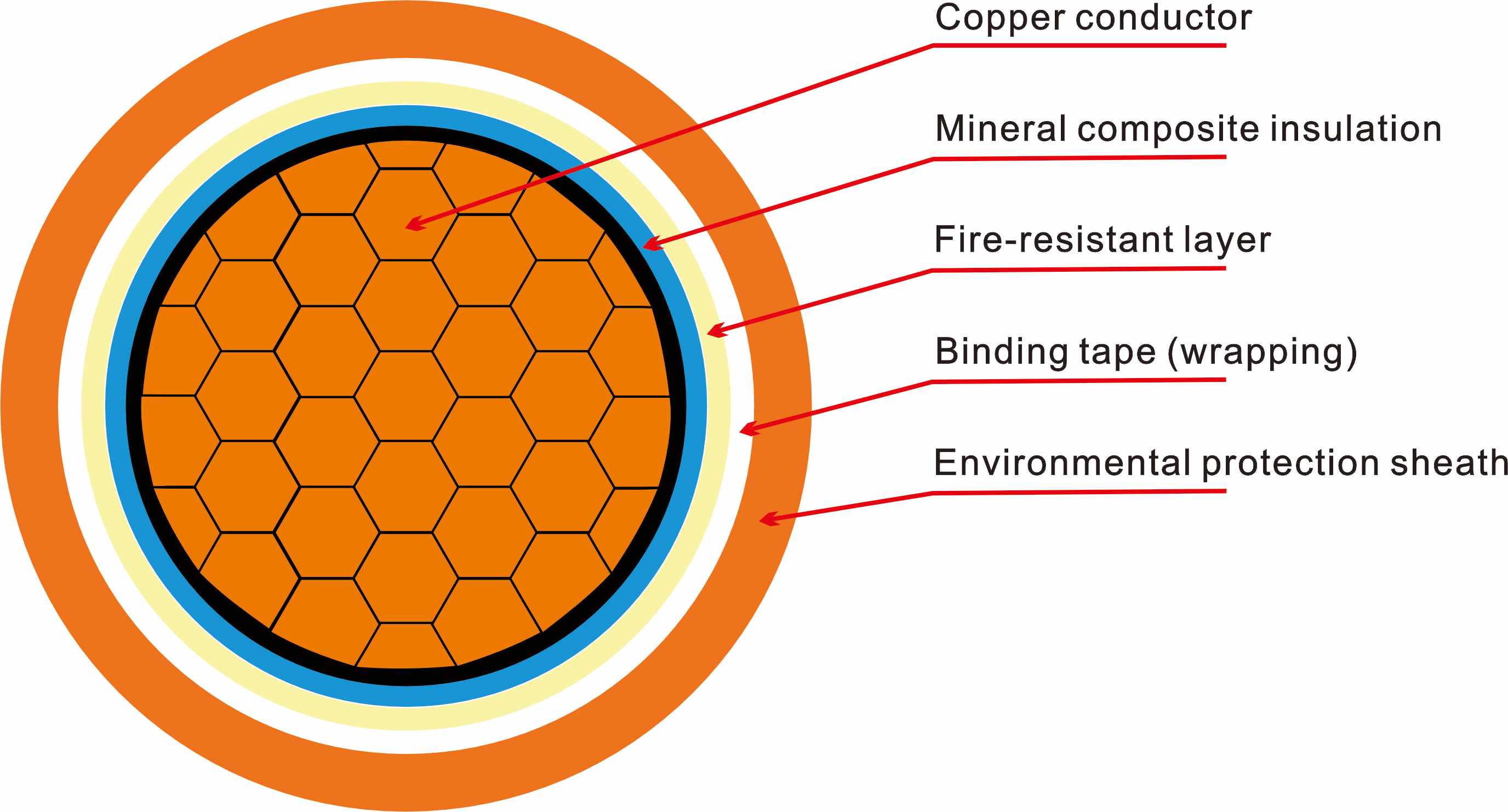

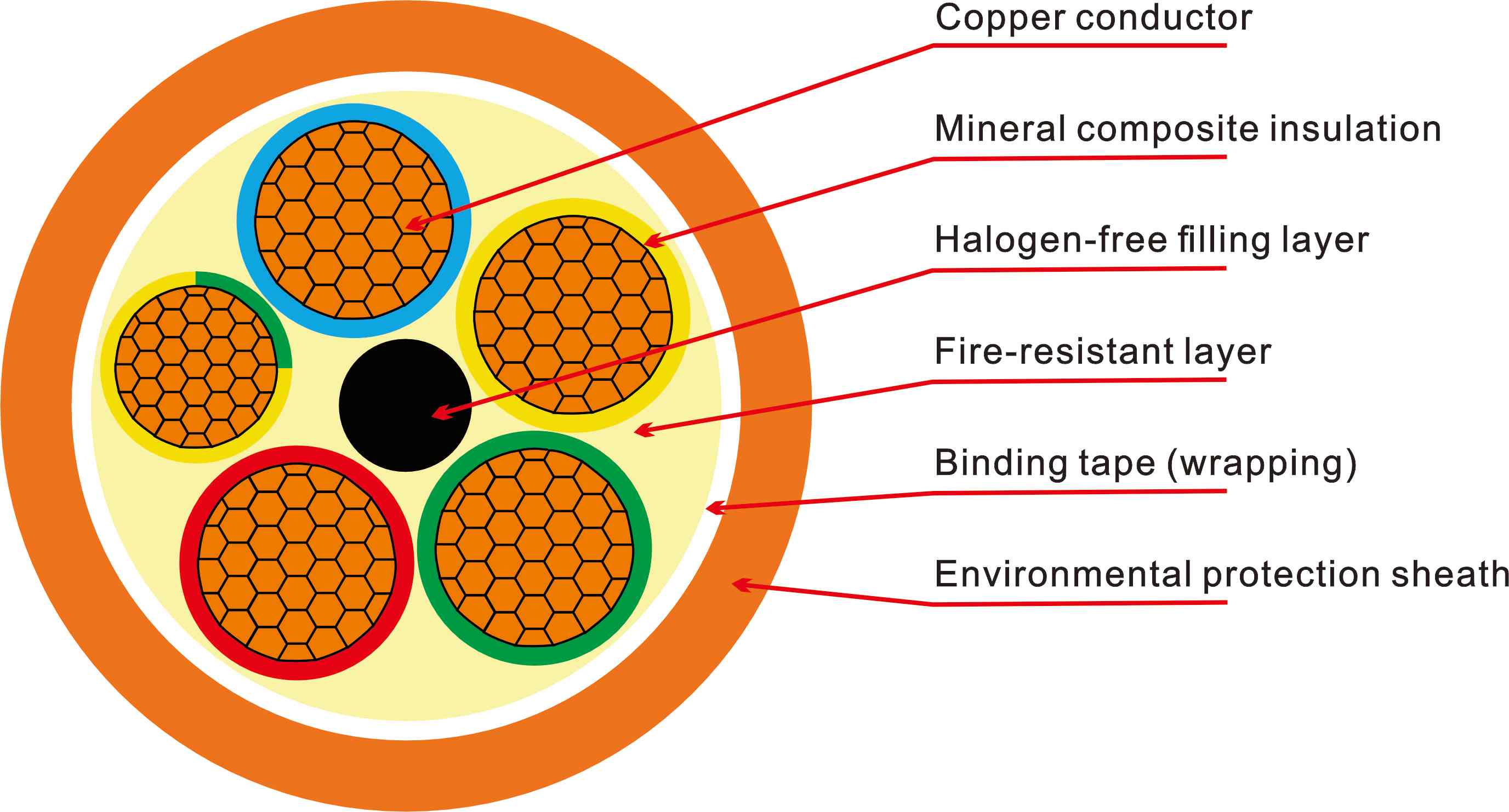

Layered from inside to outside

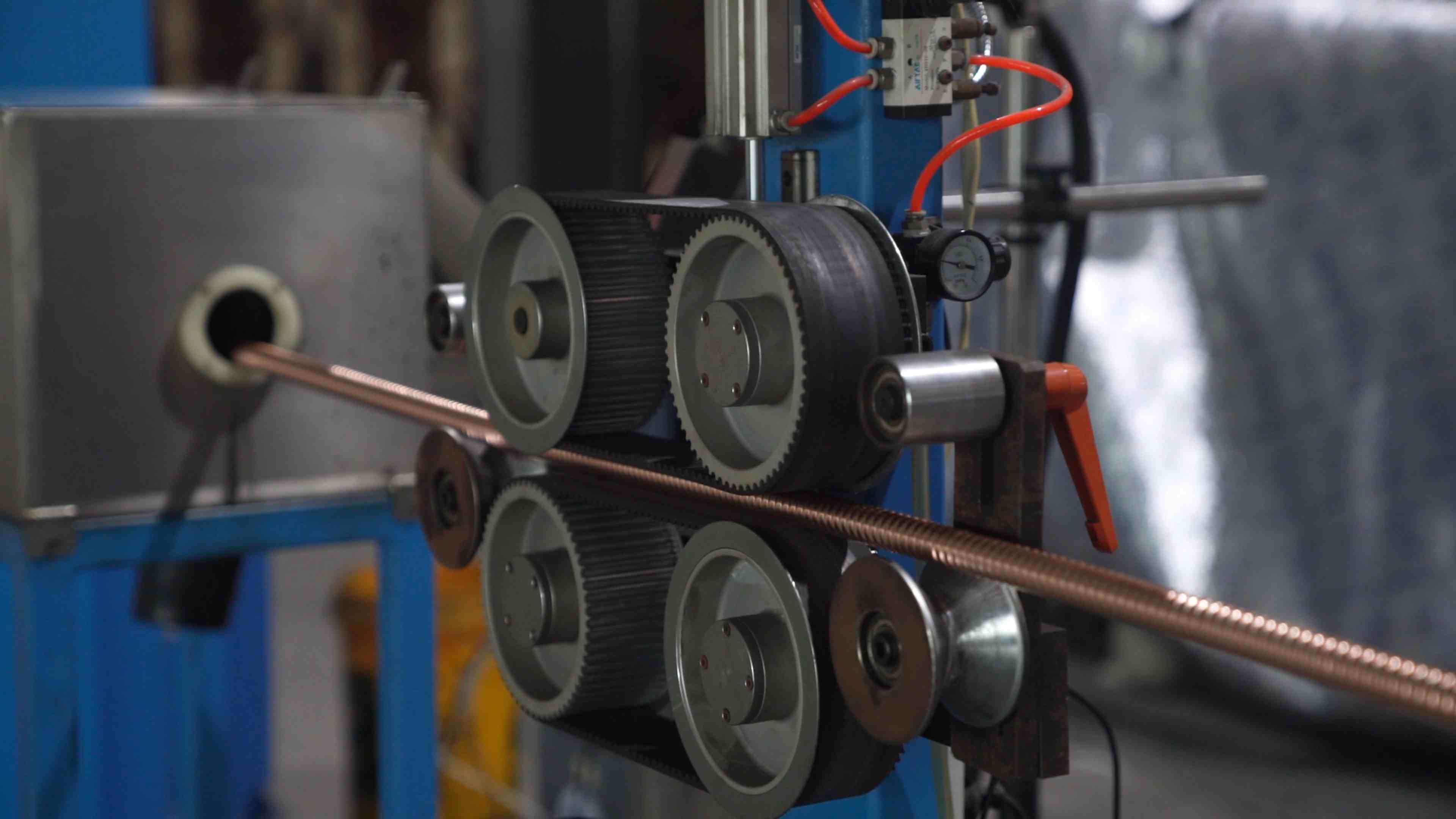

Factory photos

If you need technical support, please feel free to contact us.

Customization & Technical Support

• E-Mail: overseasales@tiankang.com

Sales Support:

• E-Mail: overseasales01@tiankanginternational.com