The Future of Stage Machinery Programming - From Virtual Design to Flawless Execution

Revolutionary Virtual-Physical Integration

"Digital Twins for Live Entertainment"

Pando 3D pioneers a groundbreaking workflow where:

✅ Virtual axes perfectly mirror physical motors (via EtherCAT/PLC)

✅ Object-based control replaces manual motor manipulation

✅ Full show lifecycle coverage from design to performance

Core Capabilities

1. Intelligent Motion Modeling

| Traditional Approach |

Pando 3D Advantage |

| Direct motor control |

Object-shape manipulation |

| Axis-by-axis programming |

Group movement presets |

| Physical trial-and-error |

Risk-free virtual validation |

Key Features:

-

256+ physical motor synchronization

-

Preset motion libraries (waves, spirals, lifts)

-

Matrix/circular array tools for rapid rigging

2. Precision Programming Tools

Timeline Editor

-

Drag-and-drop keyframe animation

-

Multi-axis coordination visualization

-

Automatic collision detection

Debugging Suite

-

Limit overrun alerts with auto-correction

-

Synchronization deviation analysis

-

90% reduction in on-site debuging time

3. Cross-Platform Control

Supported Devices:

Remote Collaboration:

Config Platform

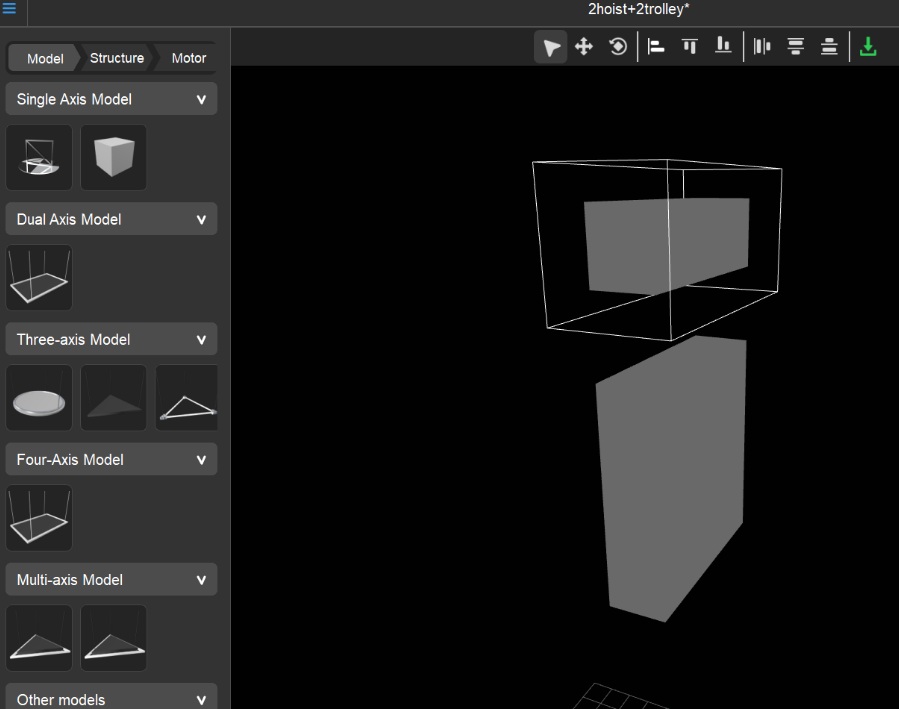

Config platform is to build constructure mode, to build easy or complicated mode is easy way here.

In this windows, you can directly import pre-made 3D models;

Or you can drag some pre-set mode, such as single axes, dual axes, 3 axes, 4 axes.

Following steps:

1, drag the mode;

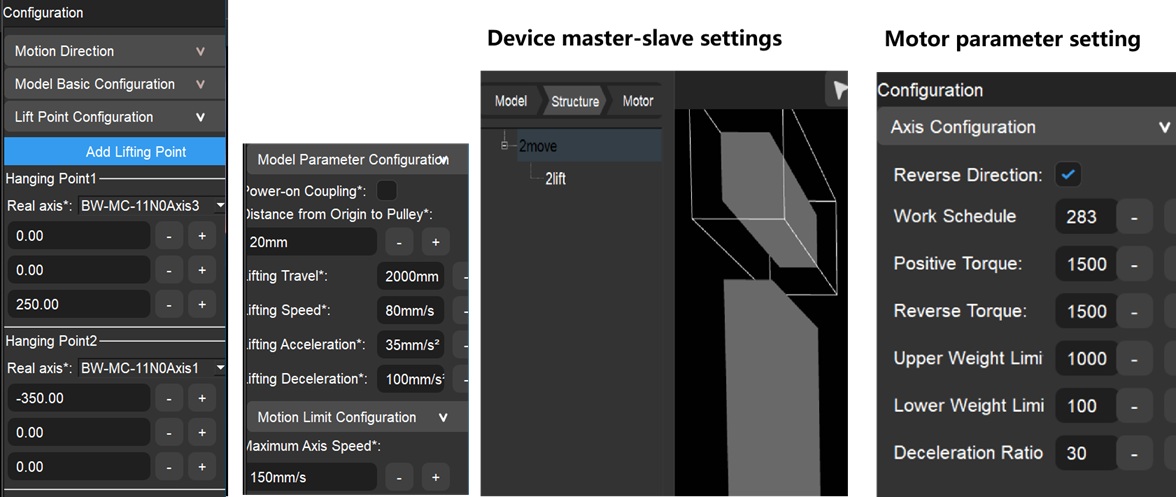

2, setting the parameter;

3, match the motor to each axes.

4, save.

Parameter setting:

in "structure" menu, you can set the device mater-slave relationship.

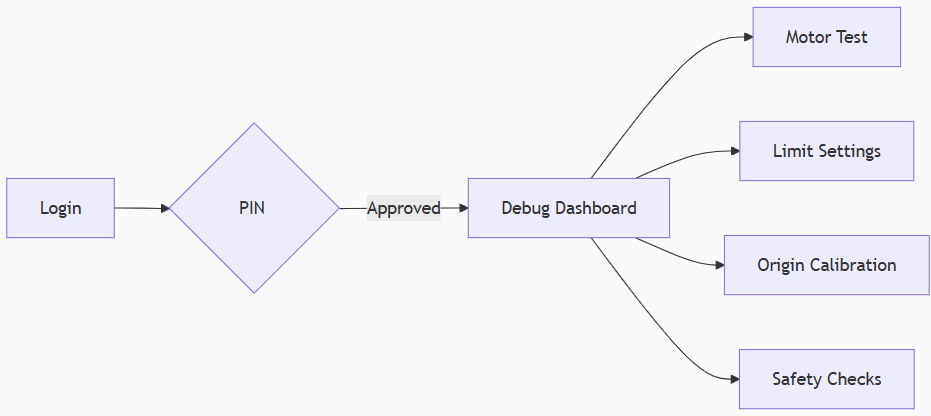

Debug Platform

(Advanced Access – For Authorized Personnel Only)

Remote Debugging Features

✅ Wireless Multi-Device Control

✅ Live System Monitoring

✅ Instant Fault Alerts

Safety Protocols

Operation Platform

1. Manual Operation Mode

Purpose: Direct motor control for setup/testing

Functions:

-

Position Direct Input

-

Posture Recall

2. Auto-Programming Mode

Timeline-Based Motion Design:

Features:

-

Drag-and-drop keyframe editing

-

Curve interpolation options:

-

Linear

-

Bézier (S-curve)

-

Step function

-

Multi-axis synchronization markers

3. DMX Integration

| DMX Channel |

Function |

| 1-16 |

Posture Selection |

| 25-32 |

Auto-Prog |

| |

Stop |

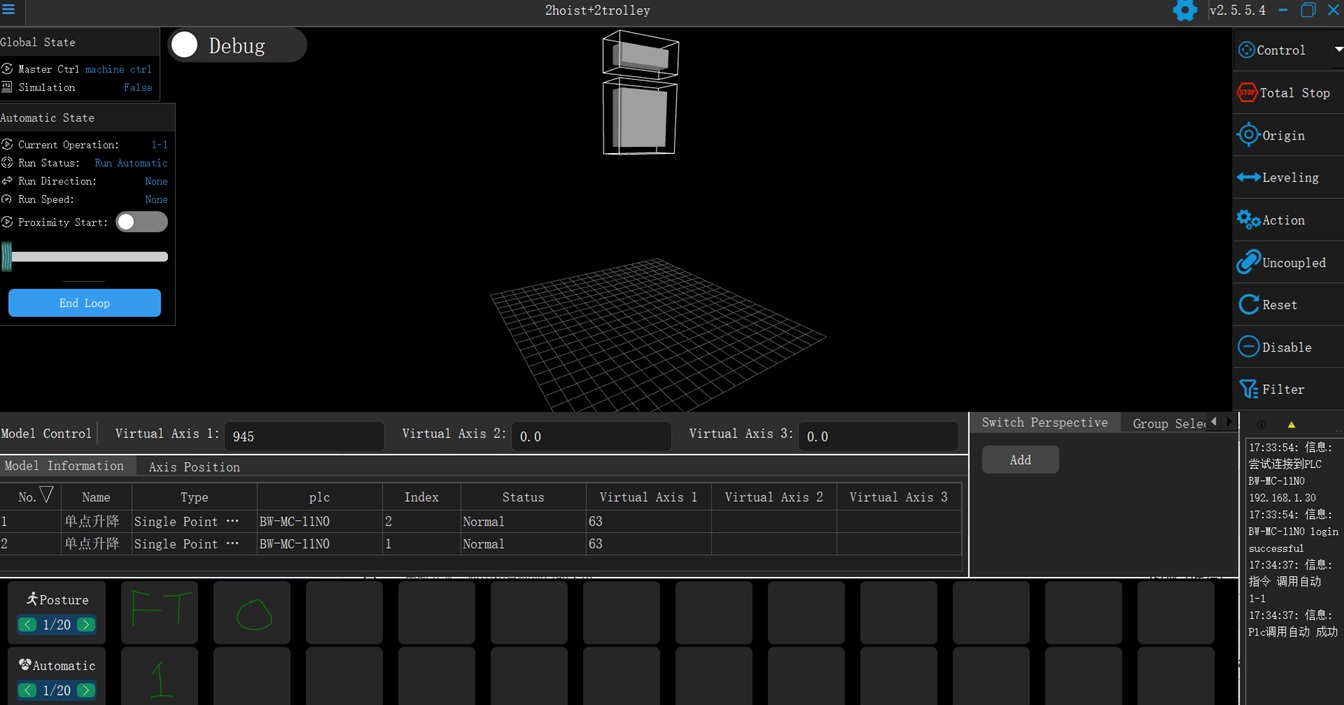

3D view and running data

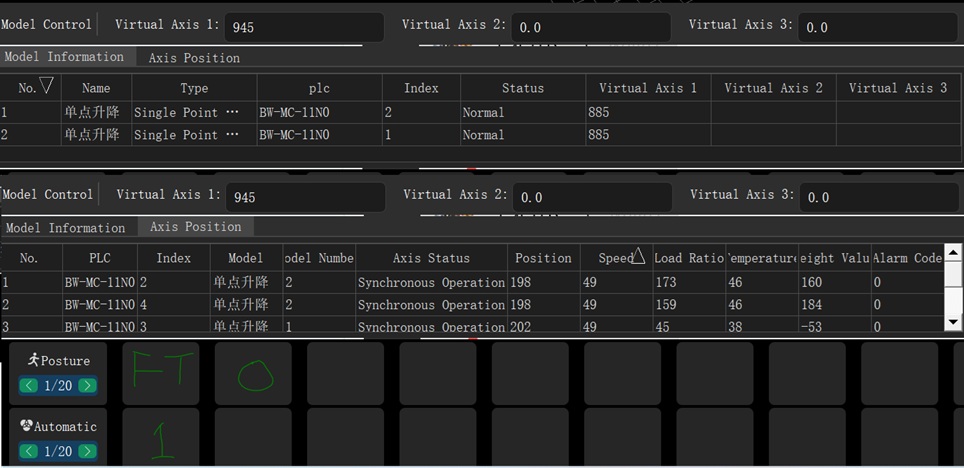

3D Monitoring & Virtual Axis Control

1. Real-Time 3D Visualization

2. Virtual Axis Mode

3. Collision Prevention

4. Data Synchronization

-

Virtual and physical motor data displayed side-by-side

-

Real-time performance monitoring

-

Automatic deviation alerts

Technical Advantages

| Category |

Specification |

| System Compatibility |

Windows/Linux |

| Cloud Storage |

Programs and models stored in cloud-based standardized mechanical library |

| Configuration Interface |

- Motor bus topology setup

- Motion/limit parameter configuration |

| Programming Interface |

- Preset motion editing

- Timeline keyframing |

| Operation Interface |

- Motion programming

- Posture playback

- Absolute positioning

- Mechanical monitoring |

| Action Storage |

360 static motions + 360 dynamic motions per project |

| Control Capacity |

- 256 axes maximum

- 128 axes in ring network |

| Controller Support |

1 main controller connection |

| Position Accuracy |

1mm |

| Time Accuracy |

0.1s |

| Language Support |

Chinese/English |