- High Precision Positioning: Utilizes a 1.8kw absolute value servo motor to achieve high precision positioning and repeat positioning, ensuring accurate movement of stage machinery.

- Strong Pulling Force: Maximum pulling force can reach 2200kg, suitable for various scenarios on hanging and ground tracks.

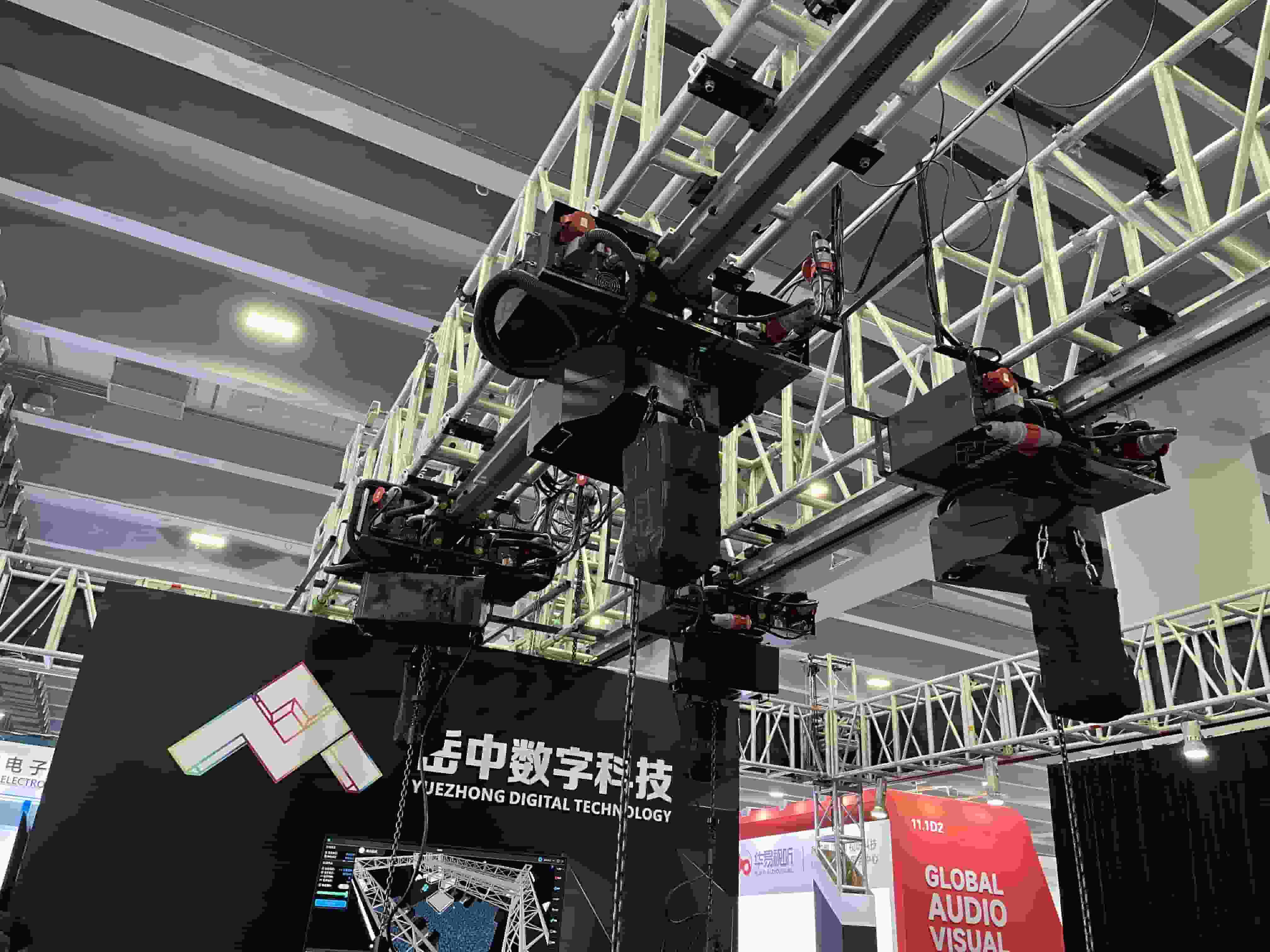

- Flexible Configuration: When moving items are overweight or oversized, it can be used in conjunction with a slave trolley or multiple power trolley to further enhance the system's load capacity.

- Self-Locking Function: All aerial powered carts come with a self-locking feature. If needed, users can adjust the clutch mechanism on the cart to disengage the trolley’s gears from the track rack, allowing manual movement of the cart to any position.

- Removable Hoist Hook: All trolley (including slave trolley) are equipped with a hoist hook underneath, compatible with CNC servo hoists. The hoist connection includes both load cell and non load cell, available as options. The hoist hook is easy to assemble and disassemble, and the bottom of the trolley is flat after removal, allowing connections with various frameworks.

- Clutch Mechanism on Power Trolley: Facilitates installation and positioning.

- Intelligent Control: Deeply integrated intelligent control system supports multi-screen coordinated control and CNC servo hoist linkage operation.

- Safe and Reliable: All components have a safety factor of over 2 times, with key components exceeding 3 times, ensuring the safety of equipment and personnel.

- Low Noise: Under standard speed and load, hanging track operation noise ≤ 55dB, ground track operation noise ≤ 65dB, providing a comfortable user environment.

- Electrical Box Suspension: The electrical box can be suspended on the side of the trolley for easy management and maintenance.

Product Advantages

(1) High Precision Positioning

The high precision positioning capability of the absolute value servo motor ensures precise control of stage machinery in various complex movements. Whether it’s stage lifting, sliding, or rotation, the system can achieve millimeter-level positioning accuracy, providing an exceptional visual effect for stage performances.

(2) Multi-Cart Formation Synchronization

Through EtherCAT real-time bus technology, the modular stage moving track cart system can achieve high-precision synchronous control of multiple carts in formation. In large stage performances, multiple track trolley can operate simultaneously, ensuring smoothness and consistency in scene transitions.

(3) Flexible Modular Design

The design of the modular trolley system allows the system to quickly adapt to various stage layouts and performance needs, enabling configuration of single or multiple trolley according to on-site arrangements. The flexible combination of standard modules and expansion options not only improves installation efficiency but also reduces maintenance costs, providing great convenience for the rental market.

(4) Strong Load Capacity

The high load capacity and strong pulling force of the power trolley meet the sliding needs of large stage machinery setups. Whether it’s heavy props or large backdrops, the system can handle them easily, ensuring the smooth progress of stage performances.

(5) High Safety and Reliability

The design of the safety factor for all components and the braking clutch function provide dual guarantees for the safe operation of stage machinery. The low noise design and convenient installation method further enhance the user experience, making it an ideal choice in the field of stage machinery.

Application Scenarios

(1) Large Stage Performances

The modular sliding trolley is suitable for various large stage performances, such as concerts, operas, and dance dramas. Its high precision positioning and multi-trolley formation synchronization capabilities can achieve complex stage movements, providing the audience with a stunning visual experience.

(2) Dynamic Exhibition Display

In the exhibition field, this system can be used for dynamic displays, showcasing large exhibits and complex backdrops. Its flexible modular design and strong load capacity can quickly adapt to different exhibition needs, enhancing the appeal and interactivity of the exhibition.

(3) Film and Television Special Effects Scenes

In film production, the modular stage moving track cart system can be used for the construction and filming of special effects scenes. Its high precision control and low noise design can meet the high requirements for scenes in film shooting, providing strong technical support for special effects production.