Prefabricated branch power cable 0.6/1kV

MAIN KEYWORDS

Prefabricated branch power cable, sub-branch power cables, prefabricated branch cables, mother power cable with son power cable, FZ-VV power cables, FZ-VV22 power cables, FZ-YJV power cables, FZ-YJV22 power cables.

PRODUCTS APPLICATION

Prefabricated branch cable is a new product of low voltage distribution system. It has the advantages of safe and reliable power supply, excellent insulation performance, simple laying and installation, low distribution cost, wide application range, many varieties, low requirements for installation environment and convenient design. Compared with bus slot, it has more functions, such as seismic, waterproof, flame retardant and fireproof, and avoids the tedious process of bus slot installation and maintenance. It is an ideal replacement for ordinary cables and bus slots.

Prefabricated branch cables are mainly used in medium and high-rise buildings, but also widely used in office buildings, hotels, hospitals, shopping centers, factories, mines, highways, tunnels, airports, Bridges, cultural and sports venues and other buildings.

PRODUCTS FEATURES

With better reliability in safe power supply

1. Conductor of main cable has no connector, better continuity to reduce failure point.

2. Branch connectors adopt mechanical manufacturing for whole process.

3. Good branch connector structure, small contact resistance and short manufacturing process, keep contact resistance from growing larger owing to copper wire being oxidized in air.

4. Great moisture-resistant performance with high seal-ability contact. Adopt fire resistant branch cable and assure normal power supply for 90 minutes when during fire.

Cost-Effective

1. Low construction cost compared with bus-ducts

2. Space-saving

3. Low installation cost owing to easy installation

4. Free maintenance

PRODUCTS STRUCTURE

---Conductor Material

Pure annealed copper wire, solid class 1, or strand class 2.

---Insulation Material (inner insulation)

PVC (polyvinyl chloride), XLPE (Cross-linked Polyethylene)

---PVC Insulation Colour

2C: brown, blue

3C: brown, blue, yellow/green

4C: brown, blue, black, yellow/green,

5C: brown, blue, black, grey, yellow/green

Remark: we will choose other colors according to the customer request.

---XLPE Insulation Colour

Natural color with colored PP tape

---Filler Material

Fiberglass tape, or PVC (Polyvinyl chloride).

---Inner Sheath (Cabling Material)

Non-woven fabrics, or PVC (Polyvinyl chloride)

---Sheath Material (out insulation)

PVC (polyvinyl chloride)

---Sheath Colour

Black, or others.

---Core Number

2~5 cores, 2C~5C.

---Voltage Rate(U0/U)

0.6/1kV, 600/1000V (Um: 1.2kV).

---Working Temperature

PVC Insulation: -15℃~+70℃.

XLPE Insulation: -15℃~+90℃.

---Minimum Bending Radius

Fixed: 12 x Out Diameter.

---Production Standard

GB/T 12706, IEC 60502, JG/T 147-2002, JB/T 10636-2006.

---Products Delivery

Within 7-15 working days as soon as we received the deposit.

PRODUCTS INSTALLATION

1. Lay out the cable tray on the wire rack (generally put the cable downstairs and pull the cable up);

2. The hoisting rope is connected to the cable through the winding machine;

3. Start the winding machine to lift up the cable (manual lifting is also available);

4. When the cable net sleeve or lifting head reaches the top of the floor, hang the net sleeve or lifting head on the hook prepared;

5. Fix the branch cable according to the regulations with special fixture;

6. Connect the branch head to the ammeter or distribution box;

7. Connect the main cable to the distribution box;

Note: laying can also be laid down from the top of the floor.

PRODUCTS USE-GUIDE

1. In order to prevent damage to cables, collision should be prevented during transportation and laying;

2. When the ambient temperature is lower than 0℃, the cable should be preheated before laying;

3. The minimum bending radius shall not be less than 20 times of the actual outer diameter of the cable;

4. For XLPE insulated PVC sheathed prefabricated branch cable, the maximum allowable continuous running temperature shall not exceed 90℃, the short-circuit temperature shall not exceed 250℃, and the short-circuit time shall not exceed 5 seconds;

5. For PVC insulated PVC sheathed prefabricated branch cable, the maximum allowable continuous running temperature shall not exceed 70℃, the short-circuit temperature shall not exceed 160℃, and the short-circuit time shall not exceed 5 seconds;

6. All branch connection parts shall be in the straight section of the line;

7. The precast branch cables laid on the line shall be fastened within 24 hours;

8. When fixing the single-core cable, the eddy current effect should be prevented, and the use of conductive metal clamps is prohibited;

9. During laying and installation, the branch lines shall not be subject to tension.

REMARK

---The above information is only for

you reference, for the formal technical data, please refer to the actual cables.

---The product can have flame retardant, fire-resistant

or Low Smoking Zero Halogen properties.

---The OEM or OBM service

will be accepted, but the customer should be provided the authorization letter to

us in advance, and the authorization letter must be true and valid.

---Hante Cable:

Embrace New Times, Co-create Xintiandi; Focus on Quality, Foremost Service.

---Hante Cable: Good

Material, Reasonable Weight, Enough Length, well-known brand wins your trust.

MAIN ADVANTAGE

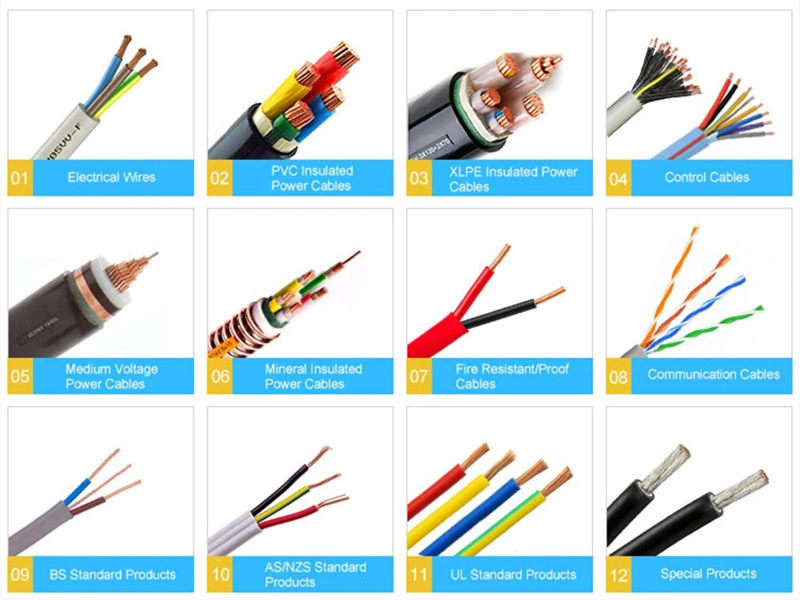

HOT-SELLING PRODUCTS

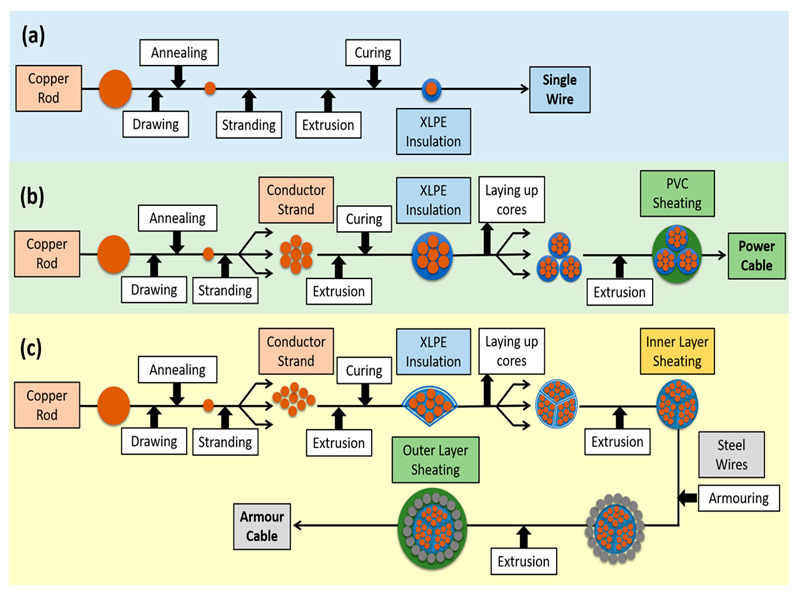

RAW MATERIAL

PRODUCTION PROCESS

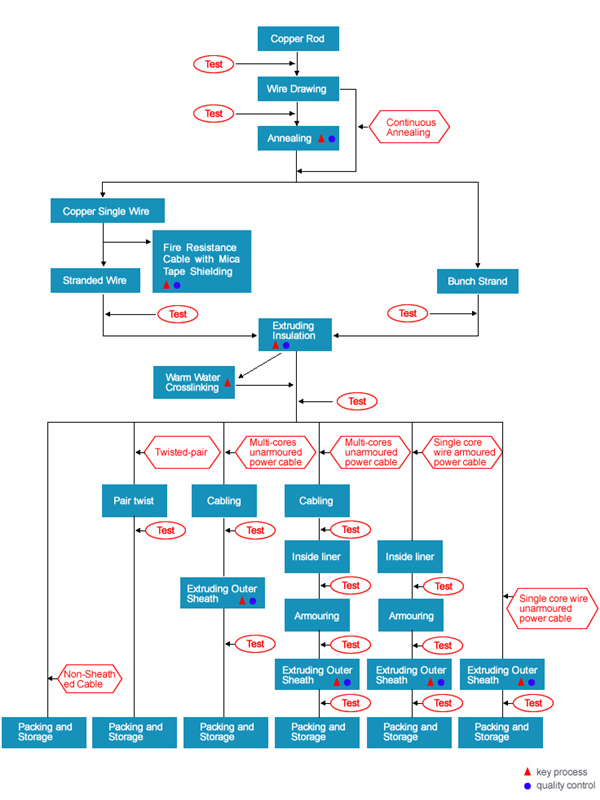

INSPECTION PROCESS

FREQUENTLY ASKED QUESTIONS

1. Are you the manufacturer or

trading company?

Wuhan Xitiandi Electrical Technology Co., Ltd (Hante Cable), is

the professional in wire and cables manufacturer. We can control your

order from the first begining to the last. Welcome to visit Hante Cable,

we'll pick you up in Wuhan airport or high-speed Railways Station.

2. How can I get a sample to test your

quality?

Hante Cable can provide the free sample to you, but you will pay the express

charges.

3. What’s your Minimum Order Quantity?

For electrical wire, the MOQ is 1000 meters; for power cable, the MOQ is 200

meters; of cources, the MOQ can be negotiated. But in order to save the

shipment space and cost for you, Hante cable suggests that the MOQ of electrical wires

should be more than 3000 meters, and the MOQ of power cable should be more than

500 meters.

4. Can I get a discount?

It depends on your quantity, we can make a discount and afford the freight. Pls

kindly contact us.

5. Does your company accept OEM production?

Yes, could print your company name, we even custom the quality card to promote

your company.