1 Product Parameters

|

Specifications

|

|

Type

|

PU/PIR Sandwich Roofing Panel

|

|

Density

|

40~45kg/m³

|

|

Thickness

|

40/50/60/75/80/100/120/150/200mm

|

|

Metal skin thickness

|

0.4~0.8mm

|

|

Panel Effective Width

|

1000mm for wall and roof

|

|

Skin material

|

PPGL,PPGI,Stainless steel,aluminum coil

|

|

Pre-painted

|

PE/SMP/HDP/PVDF etc.

|

|

Fireproof Grade

|

B1

|

|

Thermal Conductivity

|

≤0.023/≤0.02

|

|

Temperature Range

|

40~43/40~50℃

|

|

Length

|

Max 11.9m or Customized.

|

|

Customized design is welcomed.

|

2 Product Features

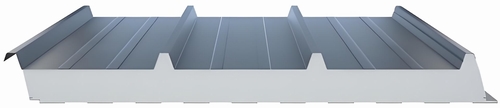

PU/PIR Sandwich Roof Panel Product Features

The panel integrates rigid polyurethane/polyisocyanurate (PU/PIR) foam core with dual corrosion-resistant facings, offering optional aluminum foil or steel layers to withstand extreme humidity/chemical exposure. Its quadruple-corrugated profile enhances bending resistance (axial load capacity: 3.5-6.0 kN/m²), enabling up to 25% purlin reduction while maintaining structural integrity. Featuring an interlocking edge design with 15° angled seams, the system achieves IP65-rated weatherproof performance. The integrated thermal insulation (λ=0.022-0.024 W/m·K) combined with Class A fire certification (EN 13501-1) eliminates secondary fireproofing layers. Pre-coated steel surfaces provide UV-resistant color retention (20-year warranty) with 12+ RAL options, minimizing on-site material waste. Installation efficiency exceeds traditional methods by 40%, with 1,200mm standard width panels reducing joint counts. Complies with ASTM C1289 and EN 14509 standards for long-term durability in -40°C to +120°C environments.

Allowable span and heat transfer coefficient of PROPANEL polyurethane roof Sandwich panel(allowable deformation f ≤ L/240)

|

Thickness (mm)

|

Heat transfer (W/m2k)

|

Weight (kg)

|

Load P=KN/m2

|

0.60

|

0.80

|

1.00

|

1.20

|

1.50

|

|

30

|

0.32

|

9.32

|

L(m)

|

2.60

|

2.30

|

2.08

|

1.91

|

1.72

|

|

50

|

0.31

|

10.15

|

L(m)

|

3.59

|

3.17

|

2.85

|

2.61

|

2.33

|

|

75

|

0.21

|

11.18

|

L(m)

|

4.64

|

4.07

|

3.66

|

3.34

|

2.96

|

|

100

|

0.19

|

12.22

|

L(m)

|

5.57

|

4.88

|

4.38

|

3.99

|

3.53

|

|

120

|

0.16

|

13.05

|

L(m)

|

6.28

|

5.49

|

4.92

|

4.48

|

3.97

|

|

150

|

0.11

|

14.30

|

L(m)

|

7.30

|

6.39

|

5.73

|

5.22

|

4.62

|

Note:0.5mm outer steel sheet and 0.4mm inner steel sheet.

3 Packing and Loading

Packing of Sandwich Panels are typically packed in two ways: with pallets and without pallets, each offering distinct advantages.

Packing with Pallets

Using pallets makes loading and unloading much easier, reducing labor costs and handling time. The panels are securely stacked on wooden or steel pallets, preventing damage and ensuring stability during transit. Palletized packing is especially beneficial for large orders, as it allows forklifts to move the panels quickly, minimizing manual work.

Packing without Pallets

For shipments where space optimization is a priority, packing without pallets is a preferred option. Without pallets, more panels can fit into a shipping container, maximizing capacity and reducing transportation costs. This method is commonly used when minimizing shipping expenses is the main concern.

Transportation

PU sandwich panels are usually shipped in standard sea freight containers. Whether palletized or not, the panels are carefully arranged to prevent movement and damage during transit. Proper securing methods, such as strapping and protective wrapping, are used to ensure the panels arrive at their destination in excellent condition.

4 Project cases of PU Roofing Sandwich Panels

Project cases of PU Roofing Sandwich Panels--Mexico cold storage project 5000 square meters

5 RFQS of PU/PIR Roofing Sandwich Panels

Ⅰ. Q: What thickness options are available for PU/PIR roofing sandwich panels?

A: Our PU/PIR roofing sandwich panels are available in 30mm, 50mm, 75mm, and 100mm thicknesses, with custom sizes available upon request to meet your specific insulation requirements.

Ⅱ. Q: How does the thermal insulation performance of PU/PIR roofing panels compare to other materials?

A: PU/PIR roofing sandwich panels offer superior thermal insulation with R-values 30-40% higher than EPS or mineral wool panels, significantly reducing energy costs in all climate conditions.

Ⅲ. Q: What is the installation process for PU/PIR roofing sandwich panels?

A: Installation is quick and simple with our lightweight PU/PIR panels featuring tongue-and-groove connections, reducing labor costs by up to 50% compared to traditional roofing methods.

Ⅳ. Q: What fire safety ratings do your PU/PIR roofing sandwich panels have?

A: Our PU/PIR roofing panels are manufactured to achieve Class B fire ratings per ASTM E84 standards, with PIR panels offering enhanced fire resistance and minimal smoke development.

Ⅴ. Q: What is the weight difference between PU/PIR roofing panels and traditional roofing materials?

A: PU/PIR roofing sandwich panels weigh approximately 10-12 kg/m², making them 60-70% lighter than concrete or clay alternatives while maintaining excellent structural integrity.