1 Product Parameters

|

Specifications

|

|

Type

|

PU-Rock wool Cold Storage Sandwich Panel

|

|

Density

|

40~45kg/m³

|

|

Thickness

|

40/50/60/75/80/100/120/150/200mm

|

|

Metal skin thickness

|

0.4~0.8mm

|

|

Panel Effective Width

|

1000mm for wall and roof

|

|

Skin material

|

PPGL,PPGI,Stainless steel,aluminum coil

|

|

Pre-painted

|

PE/SMP/HDP/PVDF etc.

|

|

Fireproof Grade

|

B1

|

|

Thermal Conductivity

|

≤0.023/≤0.02

|

|

Temperature Range

|

40~43/40~50℃

|

|

Length

|

Max 11.9m or Customized.

|

|

Customized design is welcomed.

|

2 Product Features

Unparalleled thermal insulation performance with our PU-Rock Wool Cold Storage Sandwich Panel. With a thermal conductivity of 0.019-0.022w/m·k, this panel boasts the lowest thermal conductivity in the industry, ensuring optimal energy efficiency and reduced energy consumption. Our proprietary high-pressure continuous foaming technology creates a uniform and dense foam structure, resulting in a closed cell rate of 97% and low water absorption.

Not only does our panel excel in insulation, but it also offers excellent fire resistance, meeting national standard 8624-2012 B1 level. The non-fluorinated raw materials used in our production process ensure a zero-room temperature effect, eliminating the risk of environmental pollution.

Our proprietary airtight structure technology eliminates "cold steam bridge" and ensures a seamless integration of adjacent plates, resulting in superior airtight performance. This technology is specifically designed for air conditioning warehouses, providing a reliable and efficient insulation solution.

By choosing our PU-Rock Wool Cold Storage Sandwich Panel, you can enjoy significant energy savings of up to 30%, reduced operating costs, and a reduced carbon footprint. Our panel is also easy to install, with a prefabricated design that meets all-weather construction needs.

Key Features:

Excellent thermal insulation performance

Excellent fire resistance

Non-fluorinated raw materials for environmental protection

Proprietary airtight structure technology

Easy and quick installation

Energy savings of up to 30%

3 The Technical Specifications of Cold Storage Sandwich Panel

|

Thickness /mm

|

Temperature difference between inside and outside/℃

|

Height of wall panel/m

|

Length of roof panel/m

|

Applicable cold storage temperature/℃

|

|

100

|

30

|

5

|

4.45

|

-15

|

|

125

|

35

|

5.5

|

5.2

|

-20

|

|

150

|

50

|

6

|

5.85

|

-25

|

|

175

|

65

|

6.5

|

6.3

|

-30

|

|

200

|

75

|

7

|

6.8

|

-40

|

Maintain optimal temperatures for your perishable goods with our high-performance PU-Rock wool Cold Storage Sandwich Panel. Engineered for exceptional thermal insulation, this panel utilizes a core of polyurethane (PU) and rock wool to deliver superior energy efficiency and temperature stability. The integrated rock wool also provides excellent fire resistance, ensuring the safety of your stored products.

Our cold storage panels are ideal for constructing reliable and efficient cold rooms, freezers, and chillers. Different panel thicknesses cater to specific temperature requirements for various food items. Thicker panels offer enhanced insulation for deep-freezing applications, while thinner options are suitable for chilled storage. This versatility makes our insulated sandwich panels perfect for preserving a wide range of goods, from fresh produce to frozen meats.

Built for durability and longevity, our PU-Rock wool panels offer a robust and reliable solution for your cold storage needs. Experience the benefits of superior insulation, fire protection, and adaptable design with our premium cold storage sandwich panels. Contact us today to find the perfect thickness and specifications for your specific food storage requirements.

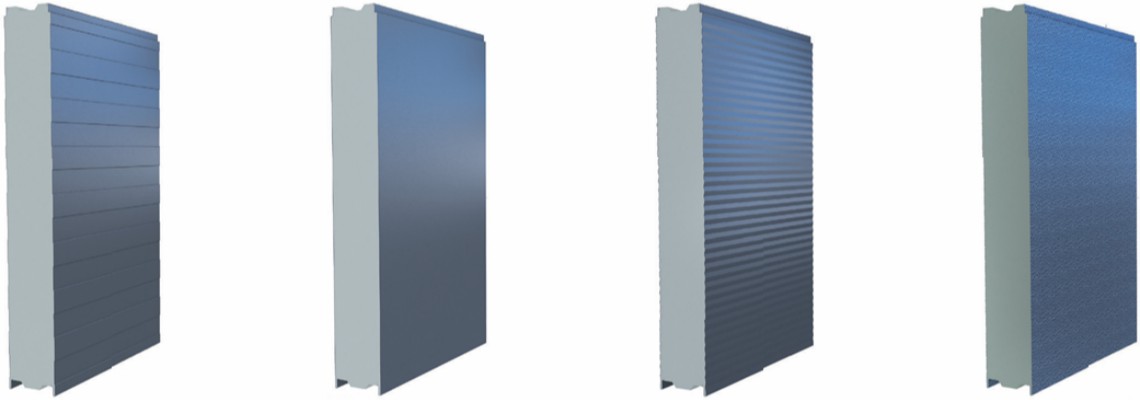

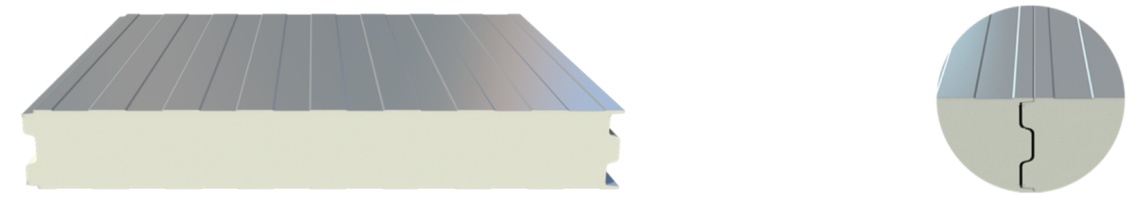

4 Plate Type and Node Figure

Cold storage board plug-in interface-C type

Cold storage board plug-in interface-E type

5 Application Areas of Cold Storage Panels

In the intricate world of food preservation, the panel excels in supporting rapid freezing processes, maintaining pristine conditions for meat, seafood, and produce throughout processing and storage facilities. Pharmaceutical and biological research environments benefit from its precise temperature management, ensuring the integrity of sensitive medicines, vaccines, and scientific specimens.

The panel's superior thermal barrier creates an optimal microclimate for dairy product storage, protecting nutritional quality and extending shelf life. Cold chain logistics receive a significant upgrade, with transportation vehicles now equipped to maintain consistent temperatures during long-distance transportation. Indoor cold storage facilities can now achieve unprecedented energy efficiency, reducing operational costs while guaranteeing product safety.

Beyond thermal performance, the panel's inherent fire-resistant characteristics provide an additional layer of safety, meeting stringent industrial safety standards. Its robust construction prevents heat transfer, minimizes condensation risks, and offers long-term durability in challenging environmental conditions.

From food processing plants to specialized medical storage, Propanel's Cold Storage Sandwich Panel represents a comprehensive solution that bridges advanced material science with critical industrial temperature management needs.