We, Bonve have rich experience in the

confectionery and sweet food industry. As the domestic first-class positive

displacement pump manufacturer, we know how to take customers' needs into

consideration. Considering the viscosity and temperature of food, our pumps

will make different changes according to each product, such as adding

insulation jacket.

What pump we offer?

Bonve offers the broadest range of its Rotary

Lobe Pumps for confectionery and sweet food industry. As an excellent pump

manufacturer, our hard technical barriers have become a powerful help for our Bonve

pumps reform and innovation. So far, Bonve pumps have developed to the fourth

generation and are mature.

Typical mediums to be transferred

Biscuit Cream, Fat, Cocoa Butter, Cocoa

Mass, Condensed Milk, Fondant, Glucose Sugar Syrup, High-Boiled, Jellies, etc.

How pump works?

The even rotation of

the rotor pair creates a vacuum on the priming side of the pump, which can be

defined by the direction of rotation of the drive. This vacuum draws the liquid

into the pump chamber. With further rotation, the pumped medium is conveyed

past the pump wall into the pressure area. Up to six chamber charges are

displaced with each drive rotation– depending on the rotor type. When the

rotor is at a standstill, the pump seals off almost completely.

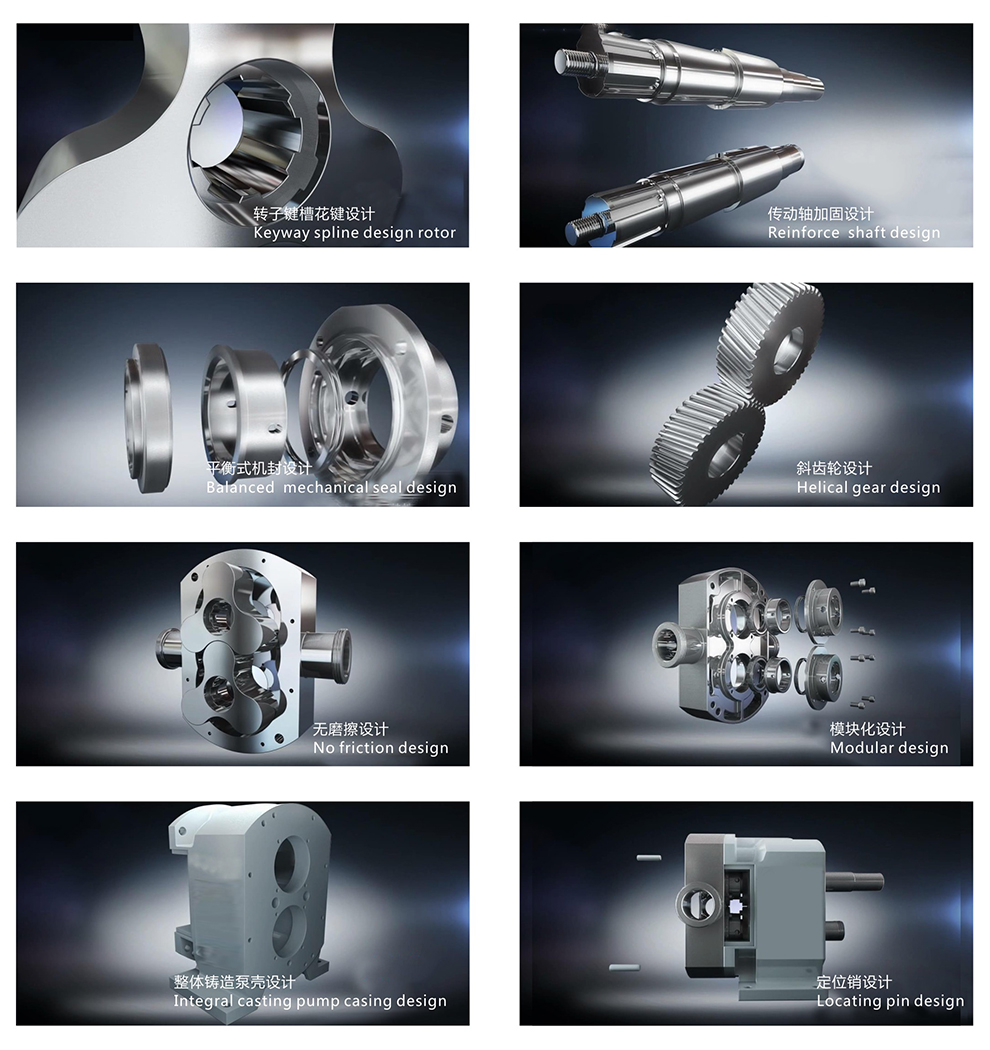

Pump

main structure

Structure

advantage

Advantages of pumps

used in confectionery industry

-

It can transport smoothly at 250 degrees Celsius

-

Gap is kept between the rotors and between the rotor

and the pump body, no friction, long life.

-

Simple assembling and disassembling, easy to

maintenance and clean, strong resistance to wearing.

-

High efficiency and energy-saving, low failure rate,

reliable sealing and low noise.

-

Special materials are used to pump materials with

solid granules, like sludge and sewage.

-

Capable to pump the viscous materials upto 1.5 million

cps and pulp with the solid volume of 60%.

-

Heating & cooling pumps is of built-in structure,

with well heat conductivity.

Who

used our pumps?

How

to choose our pump?

|

Selection Guideline

|

|

Liquid

name:___________

|

|

Viscosity: cp Density:_______ Temperature: ℃ PH

value:________

|

|

Solid content:_______ Max. size of particle:_______

|

|

Capacity: Max. required__________ L/H Working required__________ L/H

|

|

Discharge pressure: Max. required__________ Mpa Working required__________ Mpa

|

|

Connection type required: Thread[ ] Clamp[ ]

|

|

Installation type: Fixed [ ] Movable[ ]

|

|

Voltage: V Frequency: Hz

|

|

Liquid contact material: SS304[ ] 316[ ] 316L[ ]

|

|

Special

request_____________________________________

|

|

Order qty.

|

Thanks

for your trust and love to our rotary lobe pump for your confectionery

application. More details please contact our sales engineer - Mr. Andre Chen

Email: bvsales2@bonvepumps.com

Tel :

0086-574-87769810

Mobile: 0086-15888591452